I’ve only ever had glass, freshwater aquariums. But, for my first SW tank I wanted something different. Acrylic aquariums always looked sleek and cool to me, but they can be expensive. Building one was always a dream of mine but, again, once you get over 1/4” thick the prices shoot up.

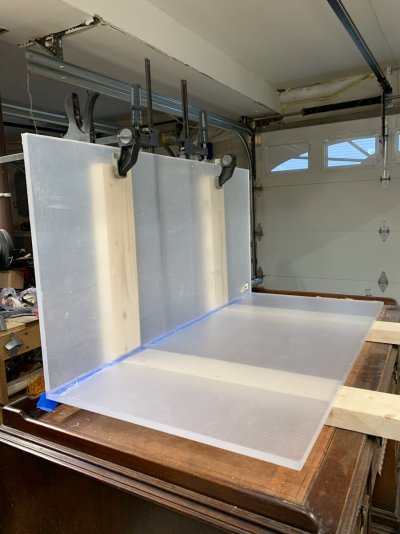

Due to an oversite at work 2, 1/2” thick, 36”x48” pieces of acrylic were accidentally ordered. My boss said I could have them, and I knew exactly what I was going to do with them!

I thought I’d document my progress and inevitably mistakes here. Maybe the info will help someone.

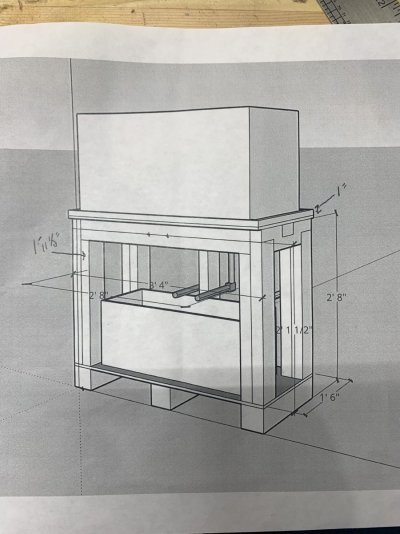

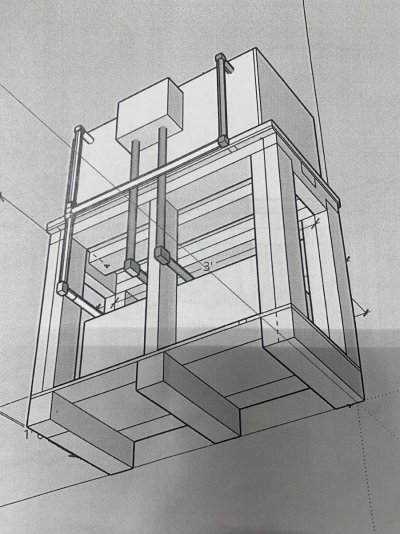

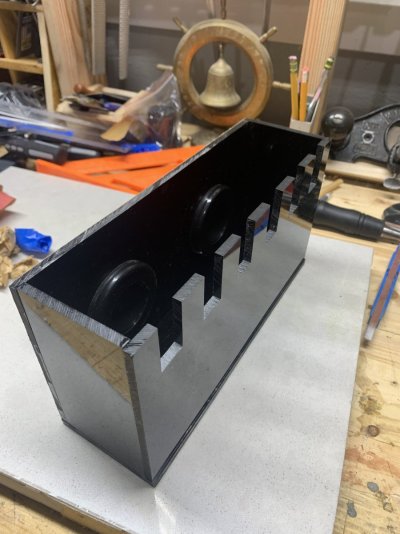

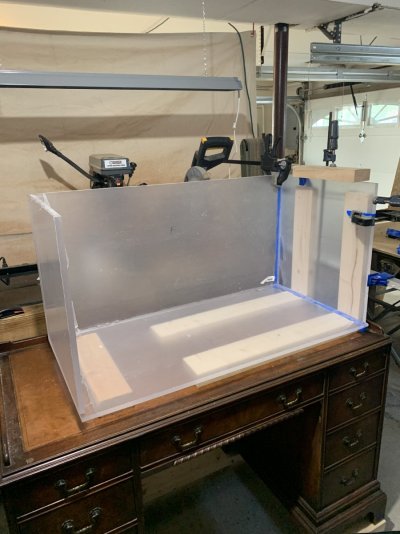

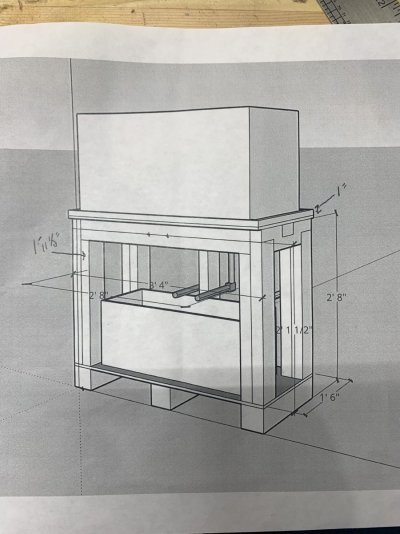

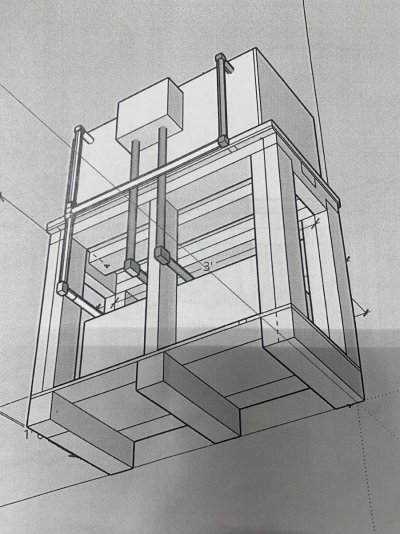

‘I started off doing TONS of research. On SW aquariums, acrylic tanks, acrylic in general, cutting, welding, plumbing, sumps, and everything else in between. I settled on making a 36"x18"x18" tank with a 20g long, glass sump. I also designed a wood stand that would accommodate the 20g sump underneath.

So, the journey begins. I’ll update this as I progress.

Due to an oversite at work 2, 1/2” thick, 36”x48” pieces of acrylic were accidentally ordered. My boss said I could have them, and I knew exactly what I was going to do with them!

I thought I’d document my progress and inevitably mistakes here. Maybe the info will help someone.

‘I started off doing TONS of research. On SW aquariums, acrylic tanks, acrylic in general, cutting, welding, plumbing, sumps, and everything else in between. I settled on making a 36"x18"x18" tank with a 20g long, glass sump. I also designed a wood stand that would accommodate the 20g sump underneath.

So, the journey begins. I’ll update this as I progress.