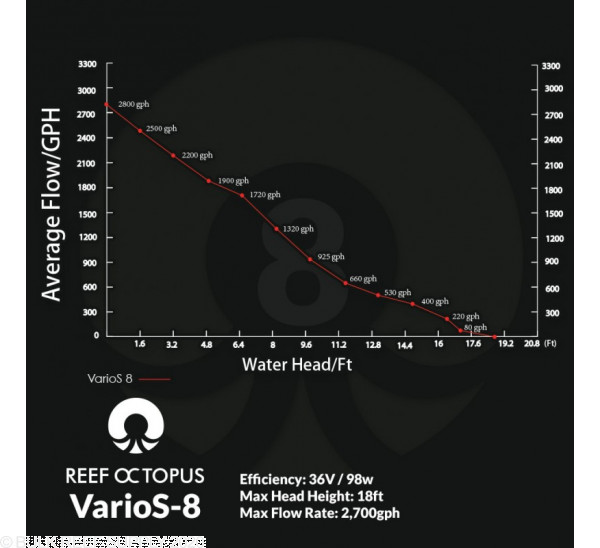

So after many weeks of waiting and a couple days of figuring out how to set the Profilux 4 up, I was finally able to get a reading from my 9000l/h flow sensor. I have the flow sensor installed before a UV sterilizer off a manifold and currently all the water is going through the sensor before entering the display tank. The pump I’m using is a Varios8 rated at 2700gph. So tell me why the flow sensor is giving me a reading of 450gph with the Varios8 on max power. I know some pressure is lost due to the plumbing, but that much?? Am I doing something wrong!?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flow Sensor 9000l/h

- Thread starter RaymondsWorlddd

- Start date

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

The GPH of the pump is based on optimal performance with 0 head loss maximum pipe size (oversized) usually with no reductions or elbows.

What size in your output pipe? How far away is the flow sensor? (Just want to make sure no turbulence). How many elbows? Can you take a picture on the placement?

If you have to go to your sump to your tank and let’s say it 4ft your going to see your GPH drop by 1000 GPH and that at optimal performance without no elbows no reductions.

What size in your output pipe? How far away is the flow sensor? (Just want to make sure no turbulence). How many elbows? Can you take a picture on the placement?

If you have to go to your sump to your tank and let’s say it 4ft your going to see your GPH drop by 1000 GPH and that at optimal performance without no elbows no reductions.

In addition to Ditto's comments also ensure that your flow sensor is toggled to the 9000l/h, I believe their smaller sensor is the default.

First have to say great plumbing job!! Very, Very neat and yes the 45 degrees are much better then 90.

The output of your pump the pump is 1.25" and you reduced it to 3/4" right out off the pump therefore you already will have head loss.

For example if you were using 0.75” tubing at a length of 5 feet and are trying to achieve a flow rate of 1000 gph, you would have an additional 3.25 feet of head pressure (0.65 x 5 feet) on your return pump. Again this is not 100% exact but provides and idea of the head pressure that needs to be calculated when using different size piping.

For example ¾” Tubing and Smaller: Add 1 foot of head pressure for every 90-degree turn.

For example 1” Tubing and Larger: Add 1/2 foot of head pressure for every 90-degree turn.

Filters: Approximately 2 to 4 feet of additional head pressure

Chillers: Approximately 2 to 4 feet of additional head pressure

UV Sterilizers: Approximately 1 to 2 feet of additional head pressure

Total Head Pressure = Pump Lift Distance + Diameter and Length of Return Tubing + Pipe Fittings + Inline Equipment

Good Website to helps calculate your head pressure: https://pentairaes.com/pump-calculator

It is best to use as large of a tube or pipe that is possible as this will minimize the amount of head pressure on your pump, and allow you to use smaller pumps.

The output of your pump the pump is 1.25" and you reduced it to 3/4" right out off the pump therefore you already will have head loss.

For example if you were using 0.75” tubing at a length of 5 feet and are trying to achieve a flow rate of 1000 gph, you would have an additional 3.25 feet of head pressure (0.65 x 5 feet) on your return pump. Again this is not 100% exact but provides and idea of the head pressure that needs to be calculated when using different size piping.

For example ¾” Tubing and Smaller: Add 1 foot of head pressure for every 90-degree turn.

For example 1” Tubing and Larger: Add 1/2 foot of head pressure for every 90-degree turn.

Filters: Approximately 2 to 4 feet of additional head pressure

Chillers: Approximately 2 to 4 feet of additional head pressure

UV Sterilizers: Approximately 1 to 2 feet of additional head pressure

Total Head Pressure = Pump Lift Distance + Diameter and Length of Return Tubing + Pipe Fittings + Inline Equipment

Good Website to helps calculate your head pressure: https://pentairaes.com/pump-calculator

It is best to use as large of a tube or pipe that is possible as this will minimize the amount of head pressure on your pump, and allow you to use smaller pumps.

There used to be a head calculator that had the flow curves from a number of pumps in it so you could see what flow you would get with your pump. I have not been able to find it any more.

Similar threads

- Replies

- 21

- Views

- 645

- Replies

- 1

- Views

- 97

- Replies

- 2

- Views

- 307