- Joined

- Jul 16, 2009

- Messages

- 3,184

- Reaction score

- 4,821

First and foremost -

DISCLAIMER: I am posting this AS IS - These are not instructions or advice. If you modify a piece of equipment, the design, implementation and responsibility for doing it safely and correctly are all yours. If you don't know exactly what you are doing then you are better of not doing it.

I have a JBJ 1/10 horsepower Chiller. the built in hysteresis is +/- 1 degree Fahrenheit. That means that if the chiller is set at 77 degrees, it will START chilling at 78 degrees and STOP chilling at 76 degrees. That is a 2 degree temperature swing. In my system, on a hot day the chiller may cycle 4-6 times a day. That is a LOT of temperature movement.

The hysteresis is not adjustable. However, I have a GHL Profilux 4 controller that can be set to as low as +/- .13 degrees Fahrenheit. This is a much tighter temperature band. The chiller will run more often, but the temperature swings will be MUCH smaller.

The issue is that if the chiller is plugged into an external temperature controller, then the whole chiller powers on and off with each controller cycle. The chiller has a built in timer that will not let it "chill" for several minutes after turning on. This also means that the display will be "off" with the chiller is off.

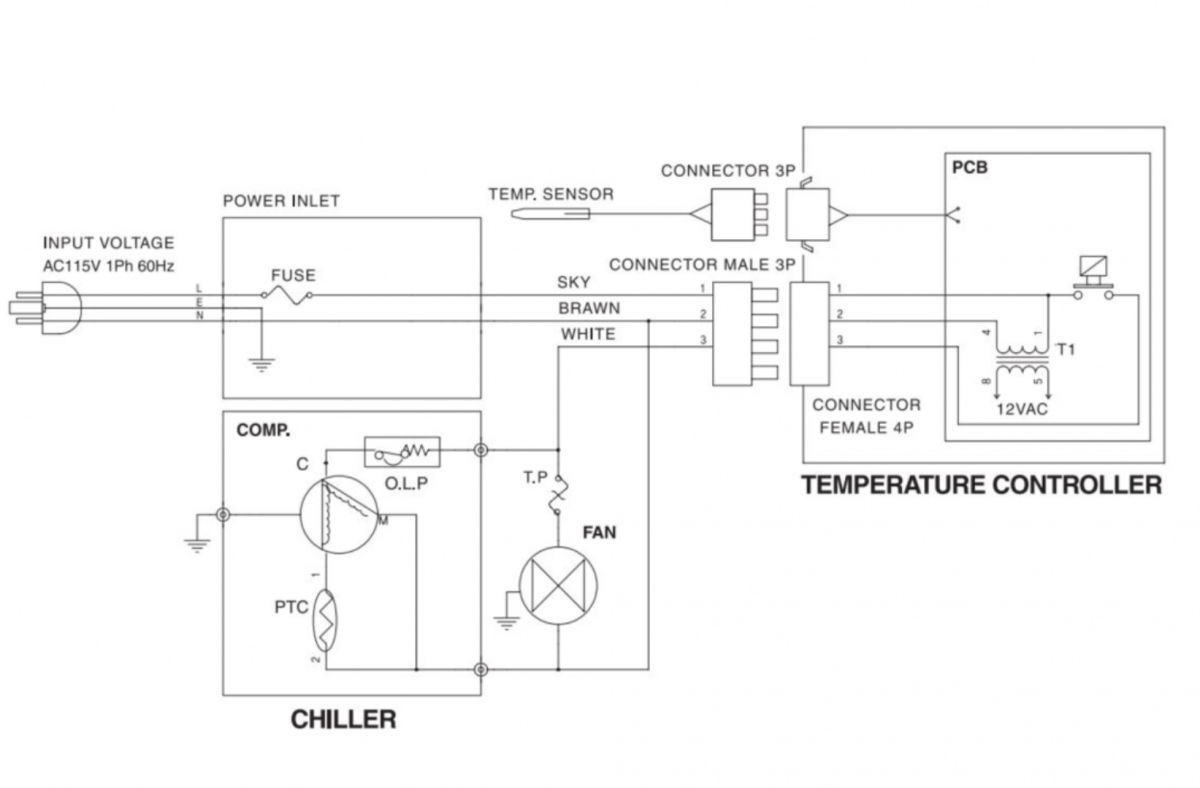

Here is the schematic for the chiller. NOTE THAT IT IS WRONG!!!!!!!

After taking the chiller apart and becoming utterly confounded with what I saw. It would appear that the line FUSE is on the NEUTRAL side (BRAWN/BROWN). The SKY (LINE) connection is the one tied directly to the COMPRESSOR and FAN and the WHITE wire (SWITCHED WIRE) is the NEUTRAL. The "C" marking on the compressor stands for "common" and is ALWAYS fed by LINE and not NEUTRAL. "M" is the motor winding and the one with "PTC" is the start winding

While this does not change the operation per-say, it does present a deviation from standards. We would typically FUSE and SWITCH the HOT conductor. That way if the fuse blows, the components inside of the machine are no longer live. Likewise in this setup, the compressor and fan ALWAYS have HOT going to them, so even when not running have live voltage to them.

Therefore, in the drawing above the "L" that is connected to "FUSE" and "SKY" is actually "N" (neutral) and the BRAWN/BROWN wire.

"N" in the schematic is actually "L" and NOT connected to BRAWN/BROWN but actually connected to "SKY".

So CONTRARY TO THE SCHEMATIC - this how is the chiller is setup.

SKY = LINE (120V) (mis-marked "N" on drawning)

BROWN = NEUTRAL (120V) (mis-marked "L" on drawing.)

When the controller calls for cooling the WHITE wire is connected to the BROWN (the nuetral) - thus energizing the fan and compressor by completing the circuit.

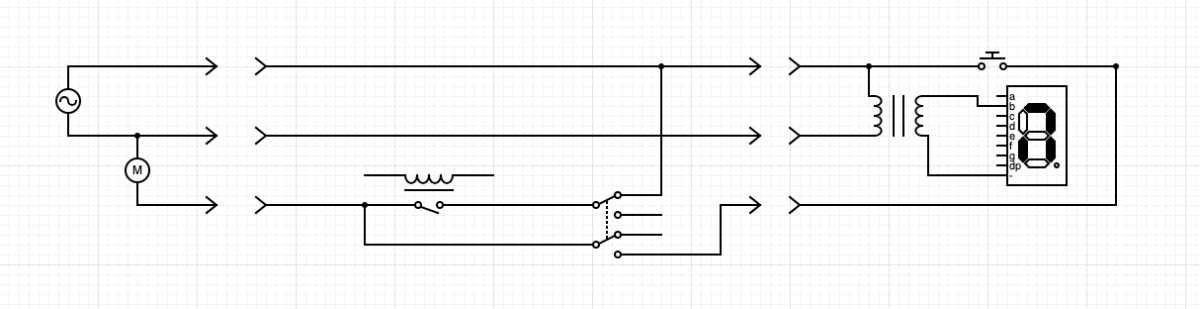

The modification is rather simple. I built a relay module with a DPDT switch to go in between the "Power Inlet and Comp." and "Temperature Controller" sections shown in the schematic above.

The DPDT switch simply allows the RELAY to control the compressor OR the built in temperature controller to control the compressor. In the drawing below the top line is NEUTRAL (BROWN). The middle line is HOT (SKY) and the bottom line SWITCHED NEUTRAL (WHITE).

Left is the Power Inlet - middle is the new module and right is the temperature controller. You can see that the relay coil is not shown connected here. In my case it is a 120V relay and connected to a switched port on my Profilux power bar.

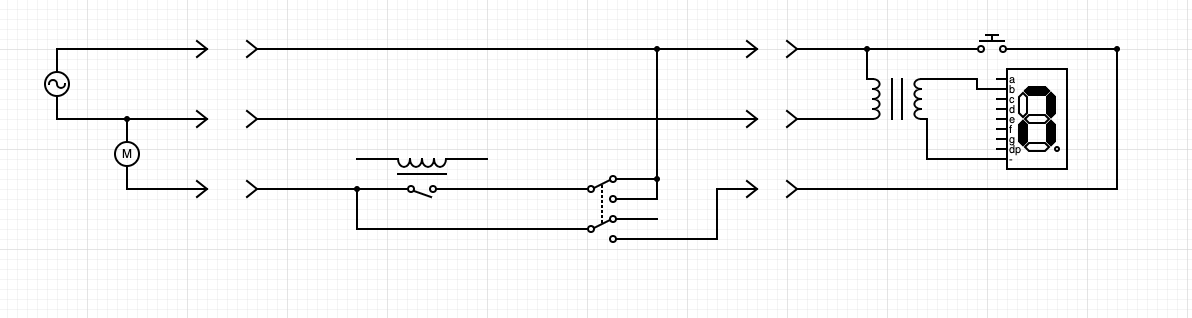

I considered an alternate approaches but decided against them for various reasons. In the schematic below, the top switch position allows for ONLY external control. The bottom switch position allows for EITHER the external or internal temperature controller to turn the chiller on, but BOTH must be off for the chiller to turn off. While these feels like a fail-safe it is confusing and the actual temperature band is hard to map out between the two competing controllers and their set point and hysteresis settings. There are others (not shown) as well.

I will post photos of the modification if I get a chance.

DISCLAIMER: I am posting this AS IS - These are not instructions or advice. If you modify a piece of equipment, the design, implementation and responsibility for doing it safely and correctly are all yours. If you don't know exactly what you are doing then you are better of not doing it.

I have a JBJ 1/10 horsepower Chiller. the built in hysteresis is +/- 1 degree Fahrenheit. That means that if the chiller is set at 77 degrees, it will START chilling at 78 degrees and STOP chilling at 76 degrees. That is a 2 degree temperature swing. In my system, on a hot day the chiller may cycle 4-6 times a day. That is a LOT of temperature movement.

The hysteresis is not adjustable. However, I have a GHL Profilux 4 controller that can be set to as low as +/- .13 degrees Fahrenheit. This is a much tighter temperature band. The chiller will run more often, but the temperature swings will be MUCH smaller.

The issue is that if the chiller is plugged into an external temperature controller, then the whole chiller powers on and off with each controller cycle. The chiller has a built in timer that will not let it "chill" for several minutes after turning on. This also means that the display will be "off" with the chiller is off.

Here is the schematic for the chiller. NOTE THAT IT IS WRONG!!!!!!!

After taking the chiller apart and becoming utterly confounded with what I saw. It would appear that the line FUSE is on the NEUTRAL side (BRAWN/BROWN). The SKY (LINE) connection is the one tied directly to the COMPRESSOR and FAN and the WHITE wire (SWITCHED WIRE) is the NEUTRAL. The "C" marking on the compressor stands for "common" and is ALWAYS fed by LINE and not NEUTRAL. "M" is the motor winding and the one with "PTC" is the start winding

While this does not change the operation per-say, it does present a deviation from standards. We would typically FUSE and SWITCH the HOT conductor. That way if the fuse blows, the components inside of the machine are no longer live. Likewise in this setup, the compressor and fan ALWAYS have HOT going to them, so even when not running have live voltage to them.

Therefore, in the drawing above the "L" that is connected to "FUSE" and "SKY" is actually "N" (neutral) and the BRAWN/BROWN wire.

"N" in the schematic is actually "L" and NOT connected to BRAWN/BROWN but actually connected to "SKY".

So CONTRARY TO THE SCHEMATIC - this how is the chiller is setup.

SKY = LINE (120V) (mis-marked "N" on drawning)

BROWN = NEUTRAL (120V) (mis-marked "L" on drawing.)

When the controller calls for cooling the WHITE wire is connected to the BROWN (the nuetral) - thus energizing the fan and compressor by completing the circuit.

The modification is rather simple. I built a relay module with a DPDT switch to go in between the "Power Inlet and Comp." and "Temperature Controller" sections shown in the schematic above.

The DPDT switch simply allows the RELAY to control the compressor OR the built in temperature controller to control the compressor. In the drawing below the top line is NEUTRAL (BROWN). The middle line is HOT (SKY) and the bottom line SWITCHED NEUTRAL (WHITE).

Left is the Power Inlet - middle is the new module and right is the temperature controller. You can see that the relay coil is not shown connected here. In my case it is a 120V relay and connected to a switched port on my Profilux power bar.

I considered an alternate approaches but decided against them for various reasons. In the schematic below, the top switch position allows for ONLY external control. The bottom switch position allows for EITHER the external or internal temperature controller to turn the chiller on, but BOTH must be off for the chiller to turn off. While these feels like a fail-safe it is confusing and the actual temperature band is hard to map out between the two competing controllers and their set point and hysteresis settings. There are others (not shown) as well.

I will post photos of the modification if I get a chance.

Last edited: