Thanks! It's easy to apply with some practice as well.That red vinyl looks really nice with the cabinet

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NXE's Red Sea Reefer Peninsula 500

- Build Thread

- Thread starter NXE

- Start date

- Tagged users None

ATO Reservoir

With the addition of a filter roller and skimmer, I did not have space in the sump compartment to use the included glass Red Sea RO reservioir, so I picked up a 25L water jerrycan:

These are cheap (£8), drinking water safe and readily available. The container stores sufficient RODI water for a week of evaporation from my tank, which is perfect.

The neck of the jerrycan was too narrow for the Tunze Osmolator pump to pass through, but I found a 12V water pump intended for caravan/motorhomes (it's a Reich Easy 14) that was slim enough and inexpensive:

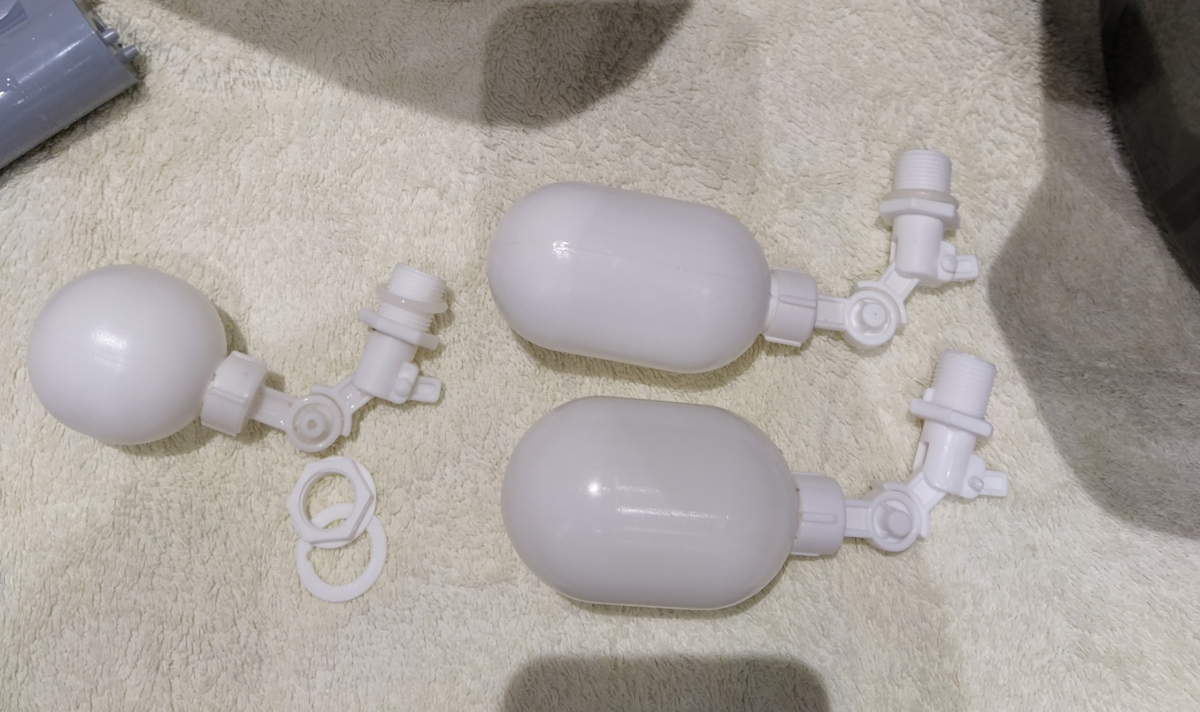

I have not had any issues with this pump, despite it running dry a few times. To prevent the container from overflowing when being filled, I added a float valve on the inlet (I had to try a few to find one that would fit through the neck of the jerrycan, this one was the winner: DIGITEN Float Valve 1/4 Inch):

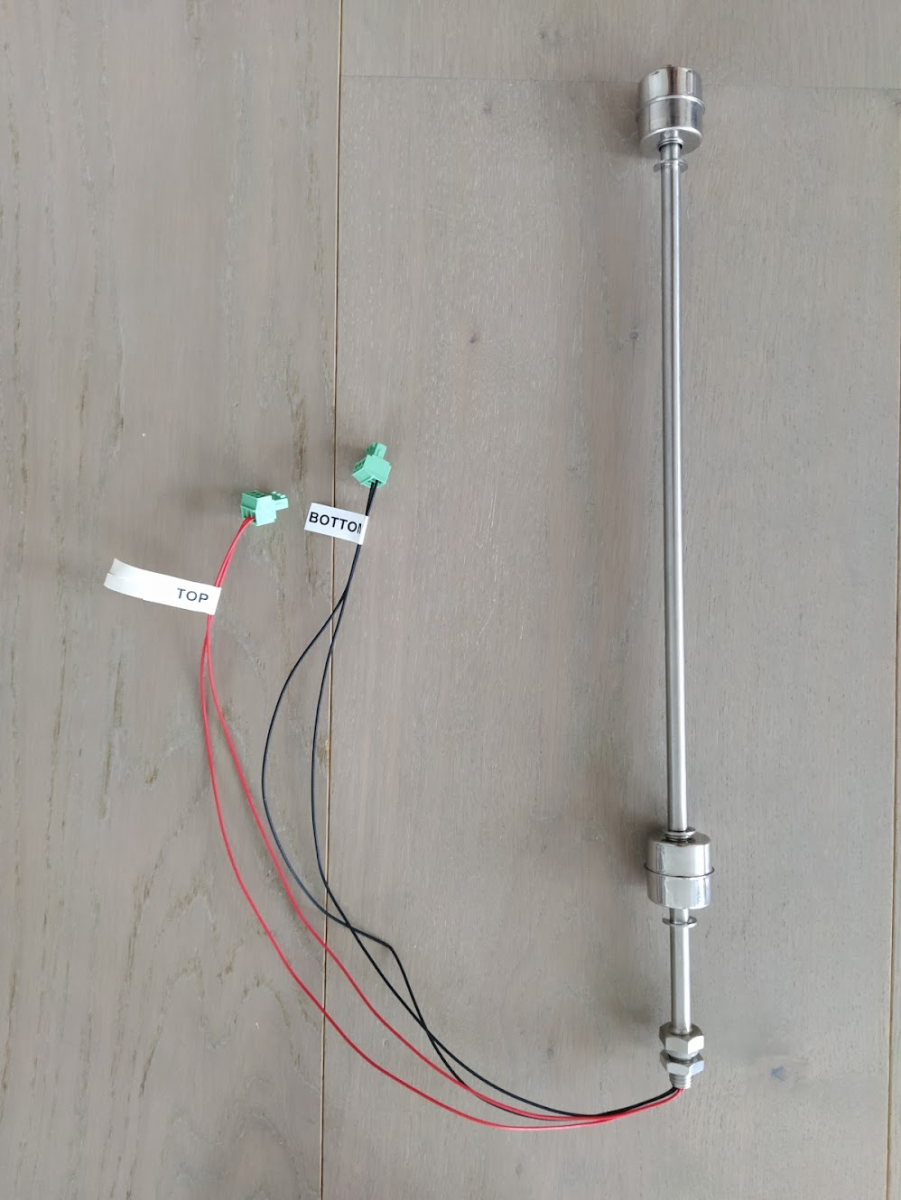

To monitor levels within the ATO container I also added some float switches:

These are wired into my reef-pi controller so that I receive notifications when the reservoir is running low:

I designed and 3d printed a small bracket that clips on to the sump wall to hold the RO and dosing lines in place:

The only issue that I have with this setup is that because the jerrycan is taller than the sump, the top 20% of the container will siphon into the sump even after the pump stops running. This is not a huge issue because it does not raise the water level too much and I cannot imagine it has any noticable affect on salinity in a tank this large, but it could be prevented by adding a siphon break.

With the addition of a filter roller and skimmer, I did not have space in the sump compartment to use the included glass Red Sea RO reservioir, so I picked up a 25L water jerrycan:

These are cheap (£8), drinking water safe and readily available. The container stores sufficient RODI water for a week of evaporation from my tank, which is perfect.

The neck of the jerrycan was too narrow for the Tunze Osmolator pump to pass through, but I found a 12V water pump intended for caravan/motorhomes (it's a Reich Easy 14) that was slim enough and inexpensive:

I have not had any issues with this pump, despite it running dry a few times. To prevent the container from overflowing when being filled, I added a float valve on the inlet (I had to try a few to find one that would fit through the neck of the jerrycan, this one was the winner: DIGITEN Float Valve 1/4 Inch):

To monitor levels within the ATO container I also added some float switches:

These are wired into my reef-pi controller so that I receive notifications when the reservoir is running low:

I designed and 3d printed a small bracket that clips on to the sump wall to hold the RO and dosing lines in place:

The only issue that I have with this setup is that because the jerrycan is taller than the sump, the top 20% of the container will siphon into the sump even after the pump stops running. This is not a huge issue because it does not raise the water level too much and I cannot imagine it has any noticable affect on salinity in a tank this large, but it could be prevented by adding a siphon break.

Battery Backup

To add battery backup for my return and flow pumps, I followed @Taxus812's incredibly useful writeup: https://www.reef2reef.com/threads/solar-generator-for-backup-power.621771/

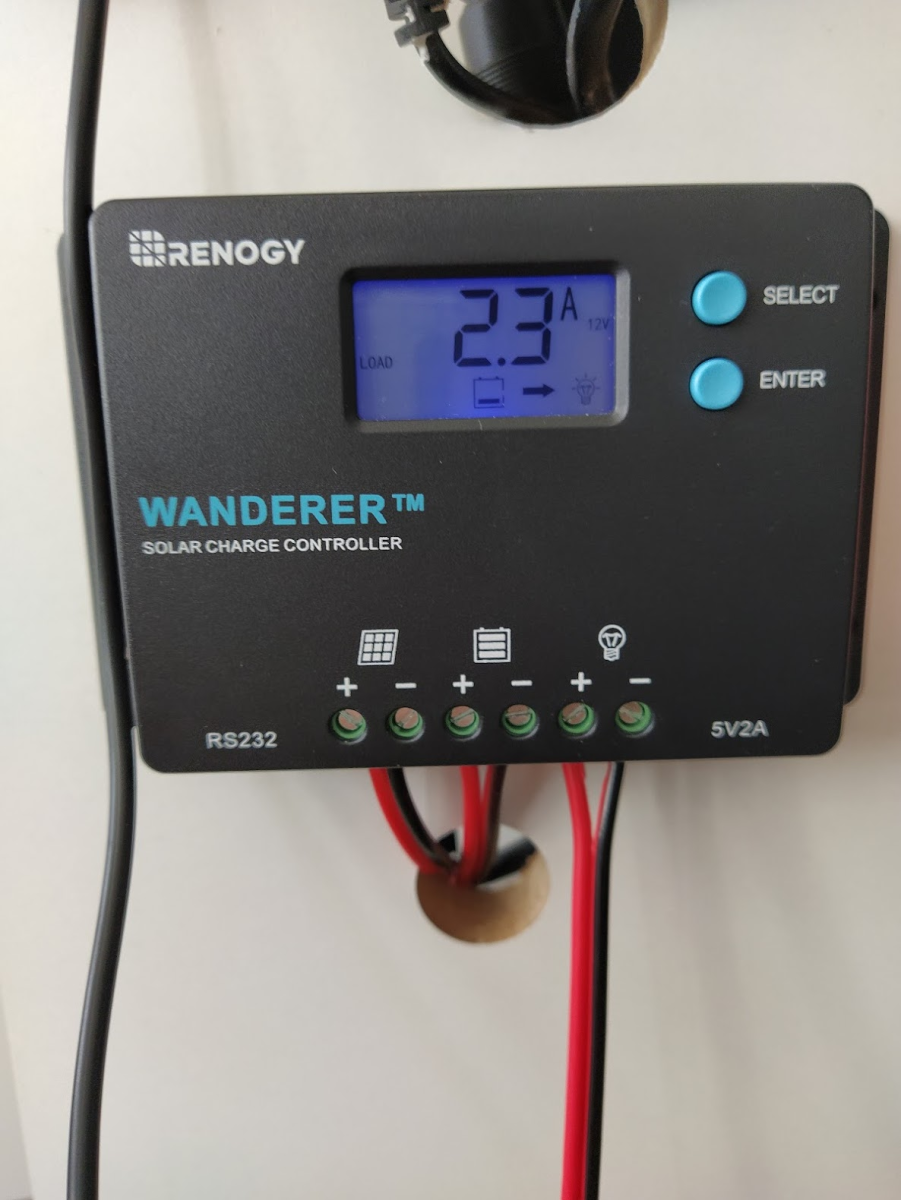

I purchased the same inexpensive Renogy solar charge controller to keep the battery charged and maintained:

While this is intended for charging a 12V battery from solar panels, it works equally well if the input load is supplied by a small power brick. I used a 15V power supply (the input load needs to be higher than 12V to charge the battery fully), but the controller can handle higher voltages so you could also use a spare 16V or 24V power supply. The controller also has an output connector which can be set to provide power only when there is no input load (i.e. if there is a power failure).

For the battery itself, I went with a Yuasa Y24-12i, which is a 24Ah 12V sealed battery. It takes up a fair amount of space:

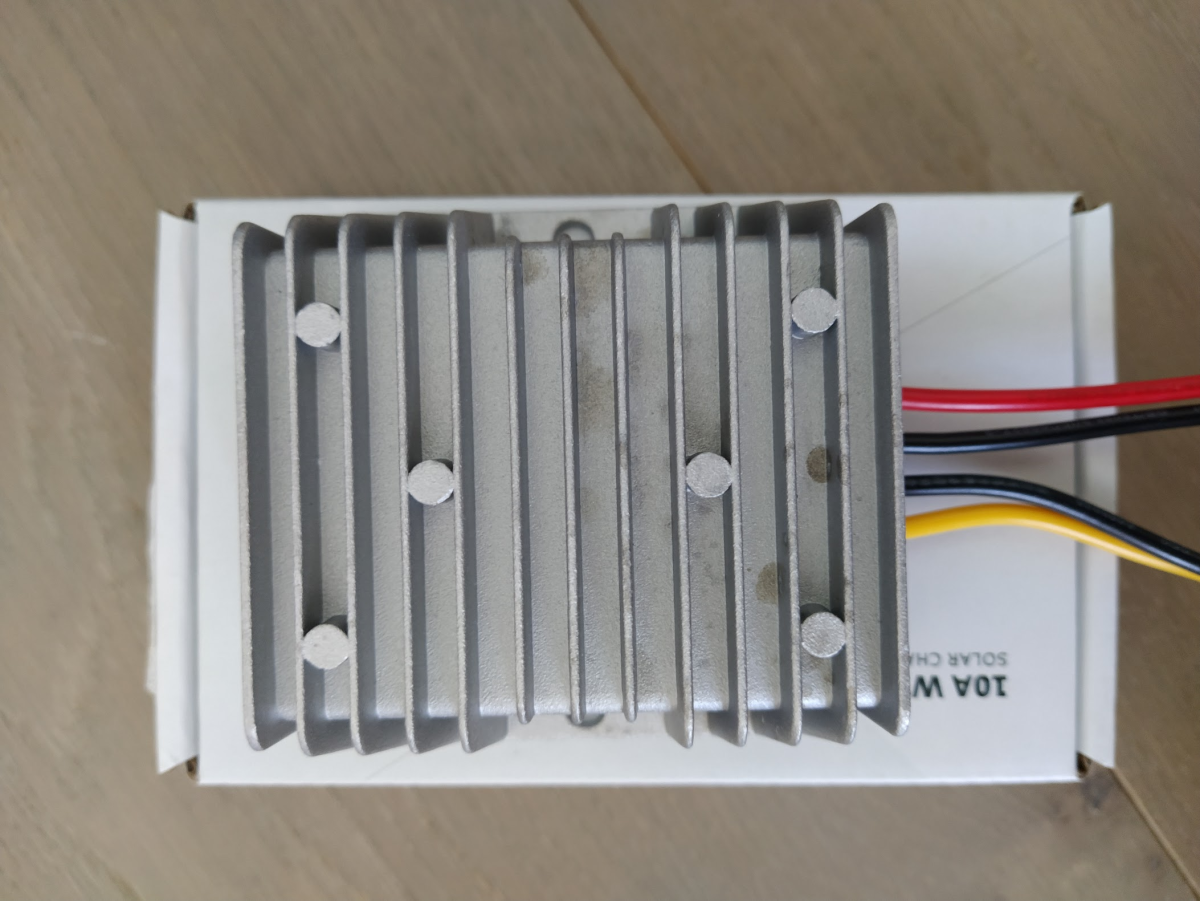

The Vectra M1 battery backup input needs to be 24V, so I bought a fairly chunky step-up convertor:

Finding the right sized jack for the Vectra M1 input was a little difficult, but I eventually discovered a usb cable with the appropciate jack that I could cut off and re-use:

Success! The Vectra M1 running on backup power alone:

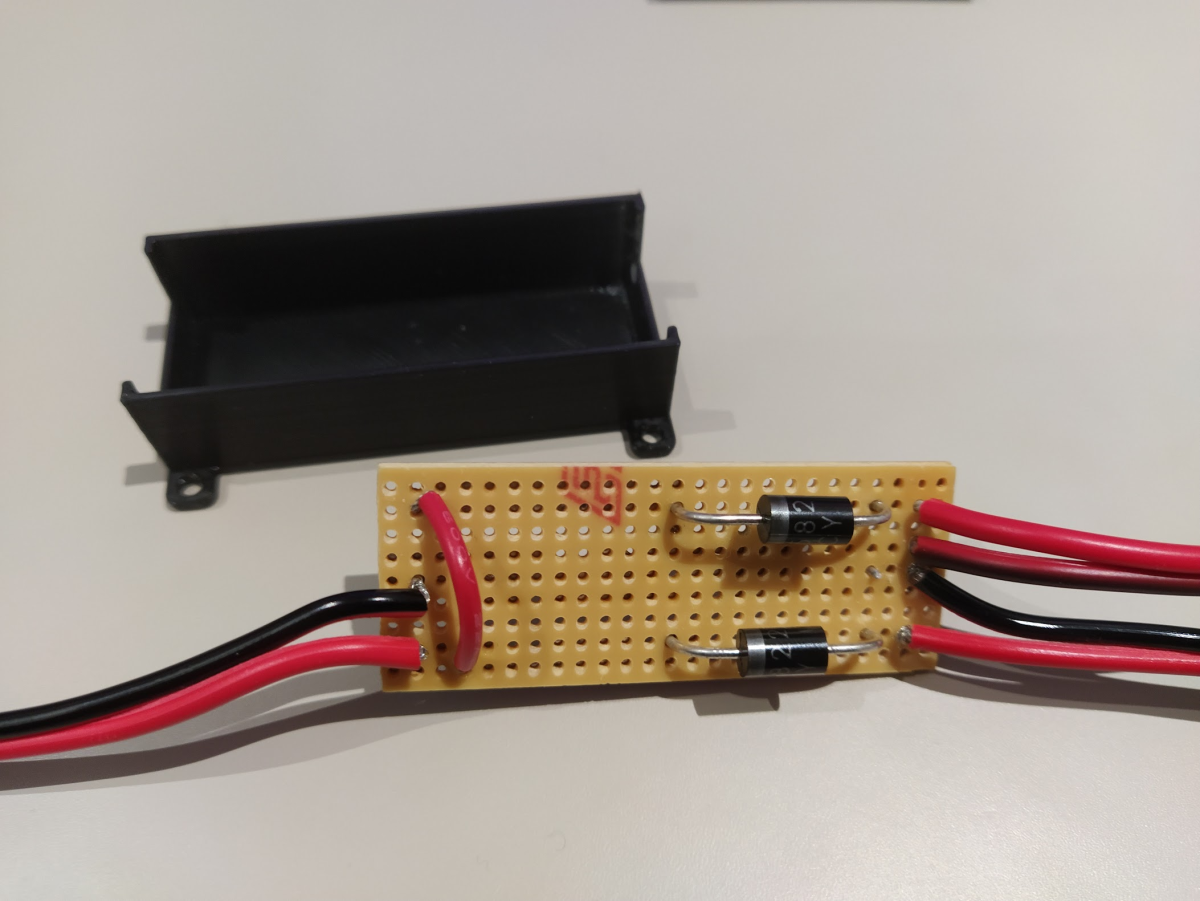

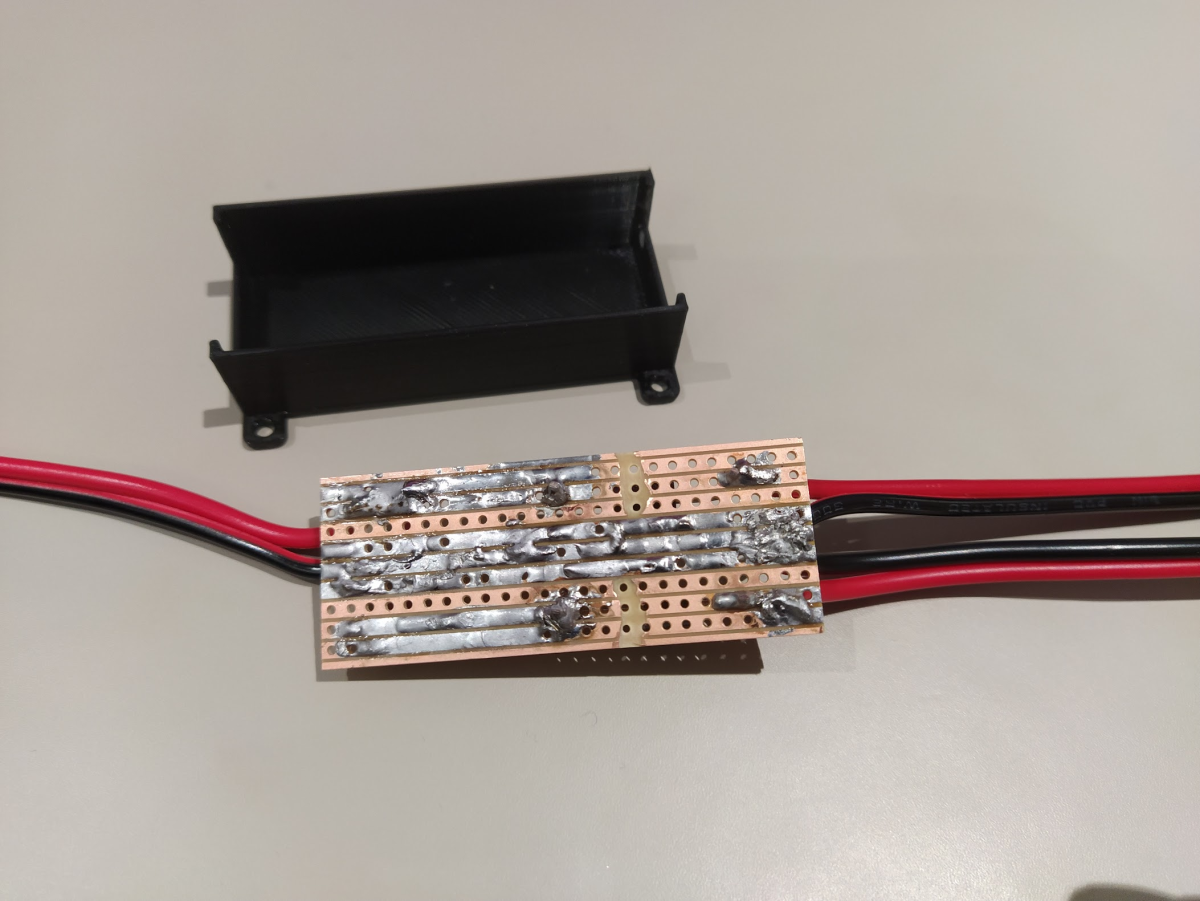

Adding battery backup to the Icecap 4K gyres was a little more difficult because the controller does not have a battery backup input, even though it has a battery power mode. The controller usually runs at 24V, but can run at 12V in 'low power' mode. Therefore, you need a way to connect both the mains-powered 24V input and battery-powered 12V input to the same power input socket without them intefering. My solution was to make a simple switching circuit using two Schottky diodes (I used 1N5822s):

This takes the 12V and 24V supplies on the right hand side and outputs a single supply to the controller, which will either be 24V or 12V depending whether the 24V input is live or not. The way this works (at least in my very basic understanding) is that the diodes only allow current to flow forwards and will not allow current flow at all if the voltage after the diode is higher that before. So if the 24V input is active, no current will flow from the 12V supply (and current from the 24V supply will not backfeed), but if the 24V supply fails current will immediately start to flow from the 12V input.

To add battery backup for my return and flow pumps, I followed @Taxus812's incredibly useful writeup: https://www.reef2reef.com/threads/solar-generator-for-backup-power.621771/

I purchased the same inexpensive Renogy solar charge controller to keep the battery charged and maintained:

While this is intended for charging a 12V battery from solar panels, it works equally well if the input load is supplied by a small power brick. I used a 15V power supply (the input load needs to be higher than 12V to charge the battery fully), but the controller can handle higher voltages so you could also use a spare 16V or 24V power supply. The controller also has an output connector which can be set to provide power only when there is no input load (i.e. if there is a power failure).

For the battery itself, I went with a Yuasa Y24-12i, which is a 24Ah 12V sealed battery. It takes up a fair amount of space:

The Vectra M1 battery backup input needs to be 24V, so I bought a fairly chunky step-up convertor:

Finding the right sized jack for the Vectra M1 input was a little difficult, but I eventually discovered a usb cable with the appropciate jack that I could cut off and re-use:

Success! The Vectra M1 running on backup power alone:

Adding battery backup to the Icecap 4K gyres was a little more difficult because the controller does not have a battery backup input, even though it has a battery power mode. The controller usually runs at 24V, but can run at 12V in 'low power' mode. Therefore, you need a way to connect both the mains-powered 24V input and battery-powered 12V input to the same power input socket without them intefering. My solution was to make a simple switching circuit using two Schottky diodes (I used 1N5822s):

This takes the 12V and 24V supplies on the right hand side and outputs a single supply to the controller, which will either be 24V or 12V depending whether the 24V input is live or not. The way this works (at least in my very basic understanding) is that the diodes only allow current to flow forwards and will not allow current flow at all if the voltage after the diode is higher that before. So if the 24V input is active, no current will flow from the 12V supply (and current from the 24V supply will not backfeed), but if the 24V supply fails current will immediately start to flow from the 12V input.

DIY Doser

I dose Aquaforest Components 123+ to maintain alk, calc and mag and vinegar to reduce nitrate. To dose them I picked up a Jebao DP-4S, which is designed to be a slave expansion unit for the DP-4 and thus is inexpensive because it does not contain a controller, just the pump heads. You can see how empty and simple the stock unit is:

The DP-4S won't work without a master unit or something else to control it. Originally, I was going to keep the DP-4S as-is and use an external adaptor to drive the dosing heads from my Robo-Tank controller running reef-pi. @Michael Lane sells a suitable adapter on his Tindie store, which is discussed here: https://www.reef2reef.com/threads/controlling-jebao-dp4-s.646234/

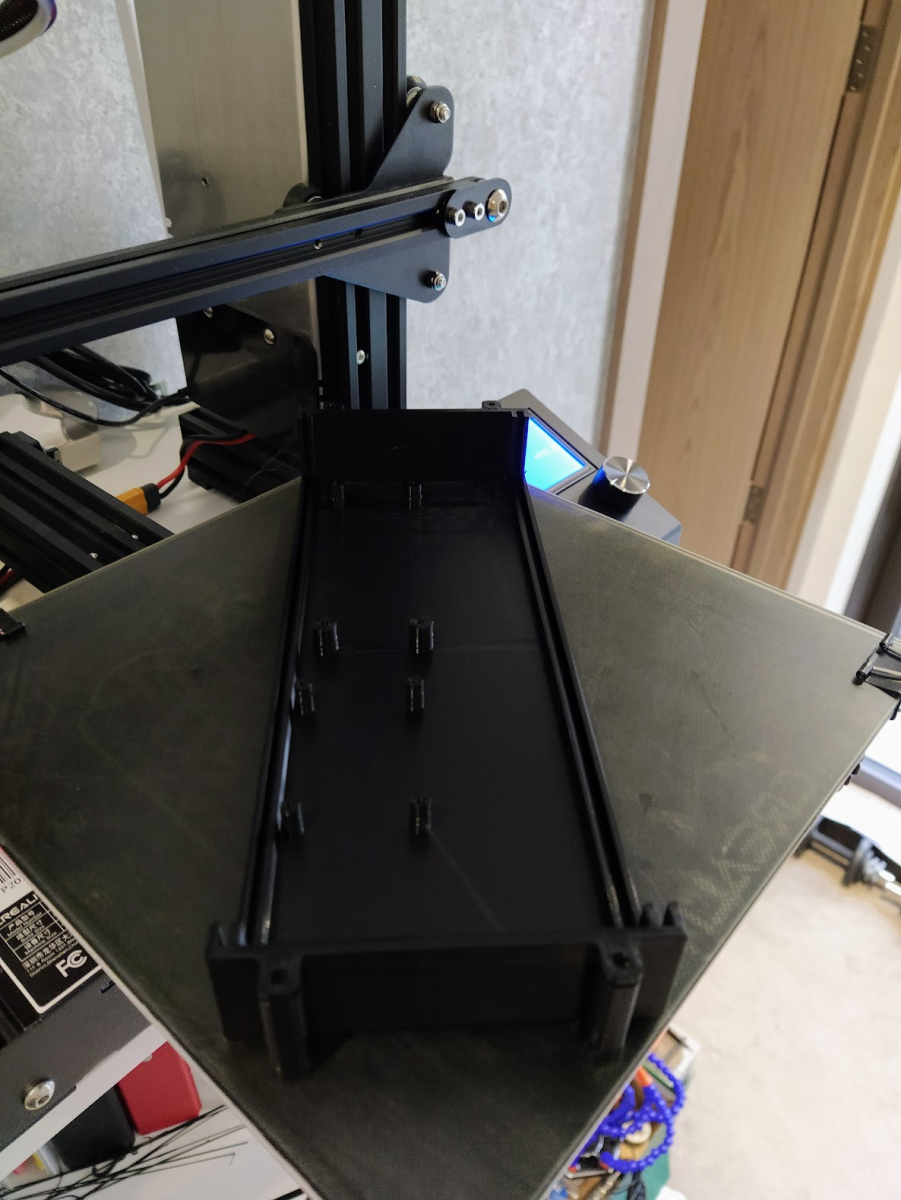

However, as space started to become very tight in my cabinet I realised I would have to downsize the doser. This also meant I could replace the cheap-looking Jebao housing with something that looked a bit better. I designed and 3d printed a new enclosure that would also house the small motor driver board to drive the dosing heads (https://www.thingiverse.com/thing:5925958):

I think it came out pretty well, and is much more compact than the original:

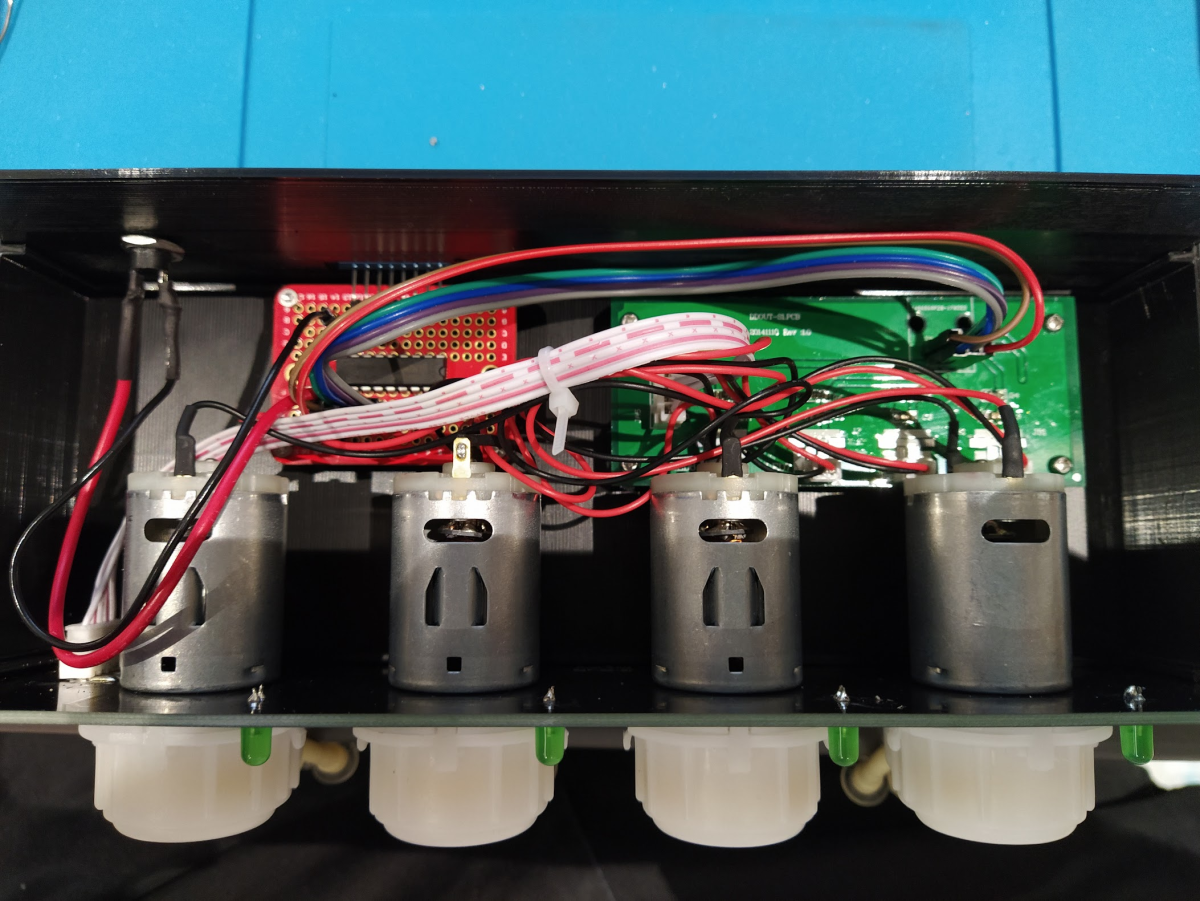

As you can see, there is little wasted space inside the new enclosure:

The red PCB is the motor driver – it uses an inexpensive ULN2803 chip to drive each dosing head and is controlled by PWM signals from my reef-pi controller. The header pins for the PWM signal (the ULN2803 could actually drive up to 8 dosing heads) and 12V power jack are at the back:

Hooked up inside the cabinet:

The doser has worked flawlessly for the last couple of years and the total cost was about £30, which compares rather favourably to commercial offerings costing upwards of £300.

I dose Aquaforest Components 123+ to maintain alk, calc and mag and vinegar to reduce nitrate. To dose them I picked up a Jebao DP-4S, which is designed to be a slave expansion unit for the DP-4 and thus is inexpensive because it does not contain a controller, just the pump heads. You can see how empty and simple the stock unit is:

The DP-4S won't work without a master unit or something else to control it. Originally, I was going to keep the DP-4S as-is and use an external adaptor to drive the dosing heads from my Robo-Tank controller running reef-pi. @Michael Lane sells a suitable adapter on his Tindie store, which is discussed here: https://www.reef2reef.com/threads/controlling-jebao-dp4-s.646234/

However, as space started to become very tight in my cabinet I realised I would have to downsize the doser. This also meant I could replace the cheap-looking Jebao housing with something that looked a bit better. I designed and 3d printed a new enclosure that would also house the small motor driver board to drive the dosing heads (https://www.thingiverse.com/thing:5925958):

I think it came out pretty well, and is much more compact than the original:

As you can see, there is little wasted space inside the new enclosure:

The red PCB is the motor driver – it uses an inexpensive ULN2803 chip to drive each dosing head and is controlled by PWM signals from my reef-pi controller. The header pins for the PWM signal (the ULN2803 could actually drive up to 8 dosing heads) and 12V power jack are at the back:

Hooked up inside the cabinet:

The doser has worked flawlessly for the last couple of years and the total cost was about £30, which compares rather favourably to commercial offerings costing upwards of £300.

Dosing Containers

Being extremely space limited I went with the VOSS 800ml glass bottles for my dosing containers. I add some push-fit connector bulkheads to the lids and also drilled a very small hole to prevent a vacuum forming:

I used some acrylic tube inside the bottles:

I printed a simple holder (https://www.thingiverse.com/thing:5925997) to keep the bottles together and they fit perfectly in the remaining space in the stand:

Connected up to the doser:

It's a tight fit with the ATO reservoir added as well:

Being extremely space limited I went with the VOSS 800ml glass bottles for my dosing containers. I add some push-fit connector bulkheads to the lids and also drilled a very small hole to prevent a vacuum forming:

I used some acrylic tube inside the bottles:

I printed a simple holder (https://www.thingiverse.com/thing:5925997) to keep the bottles together and they fit perfectly in the remaining space in the stand:

Connected up to the doser:

It's a tight fit with the ATO reservoir added as well:

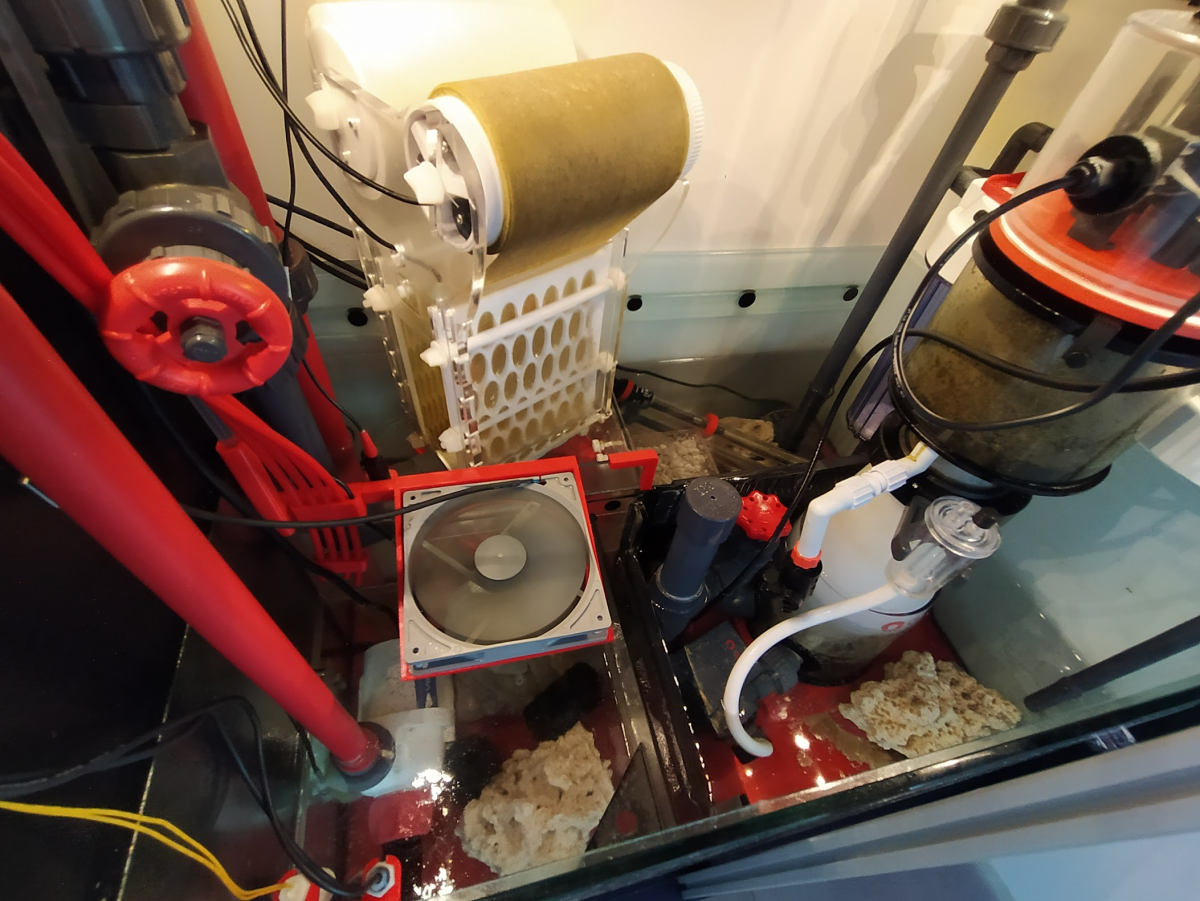

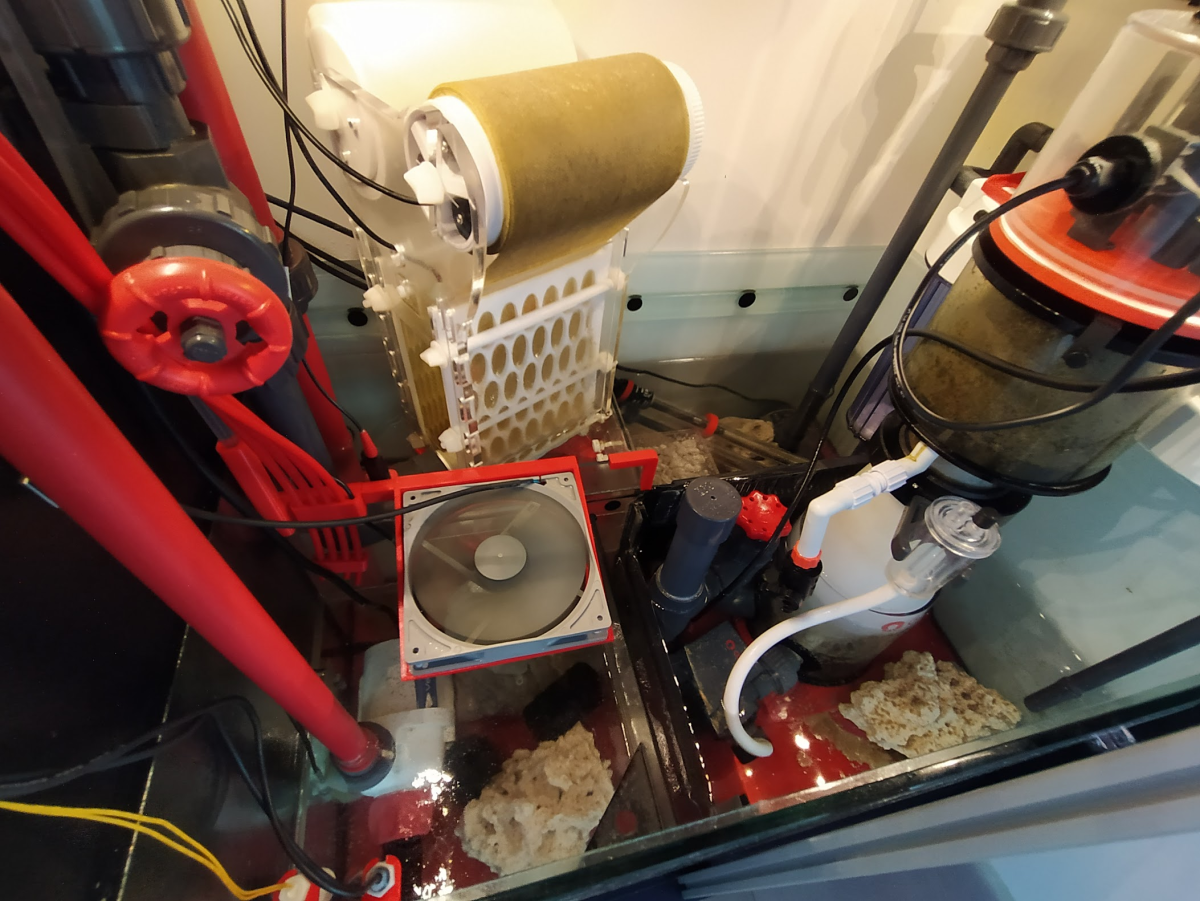

Clarisea SK-5000 Modifications

I made a couple of modications/improvements to my Clarisea SK-5000 over the last couple of years.

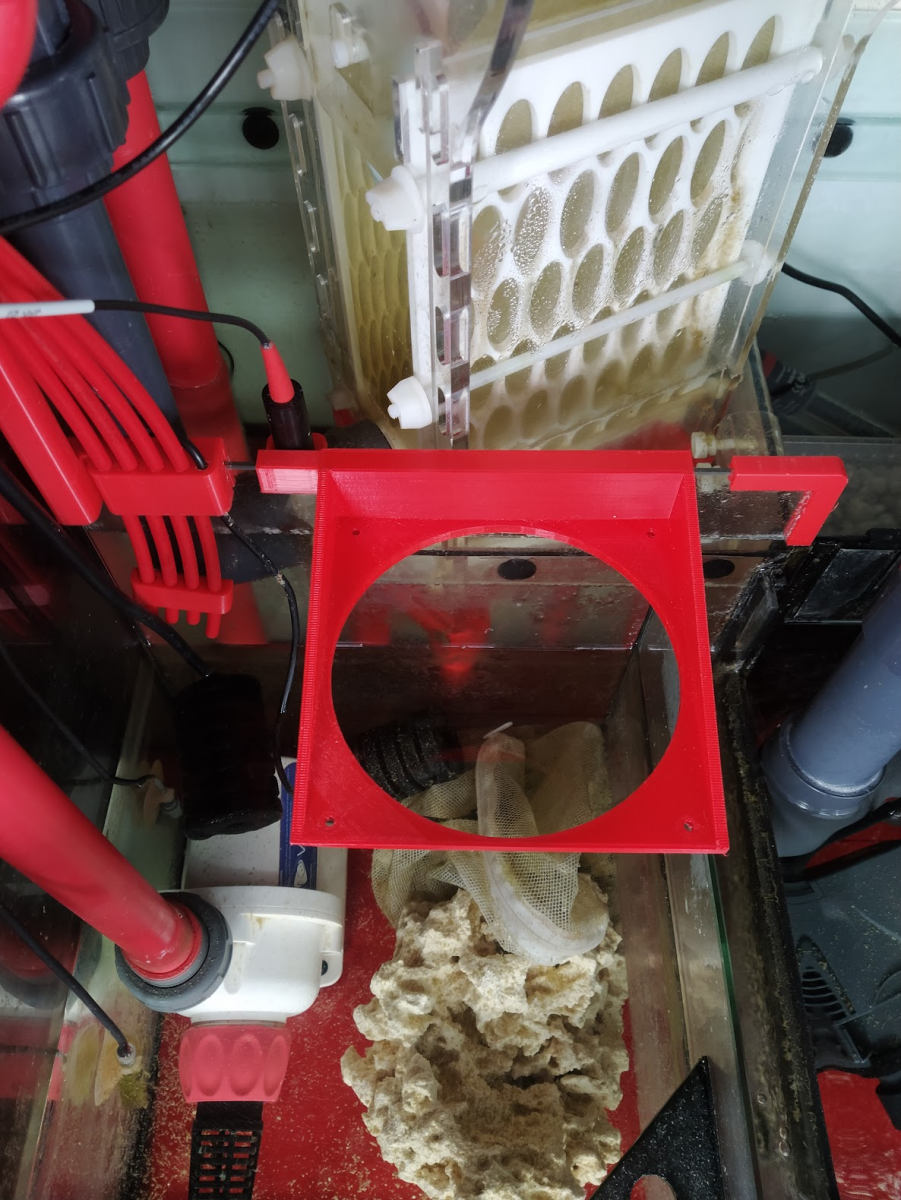

Stand

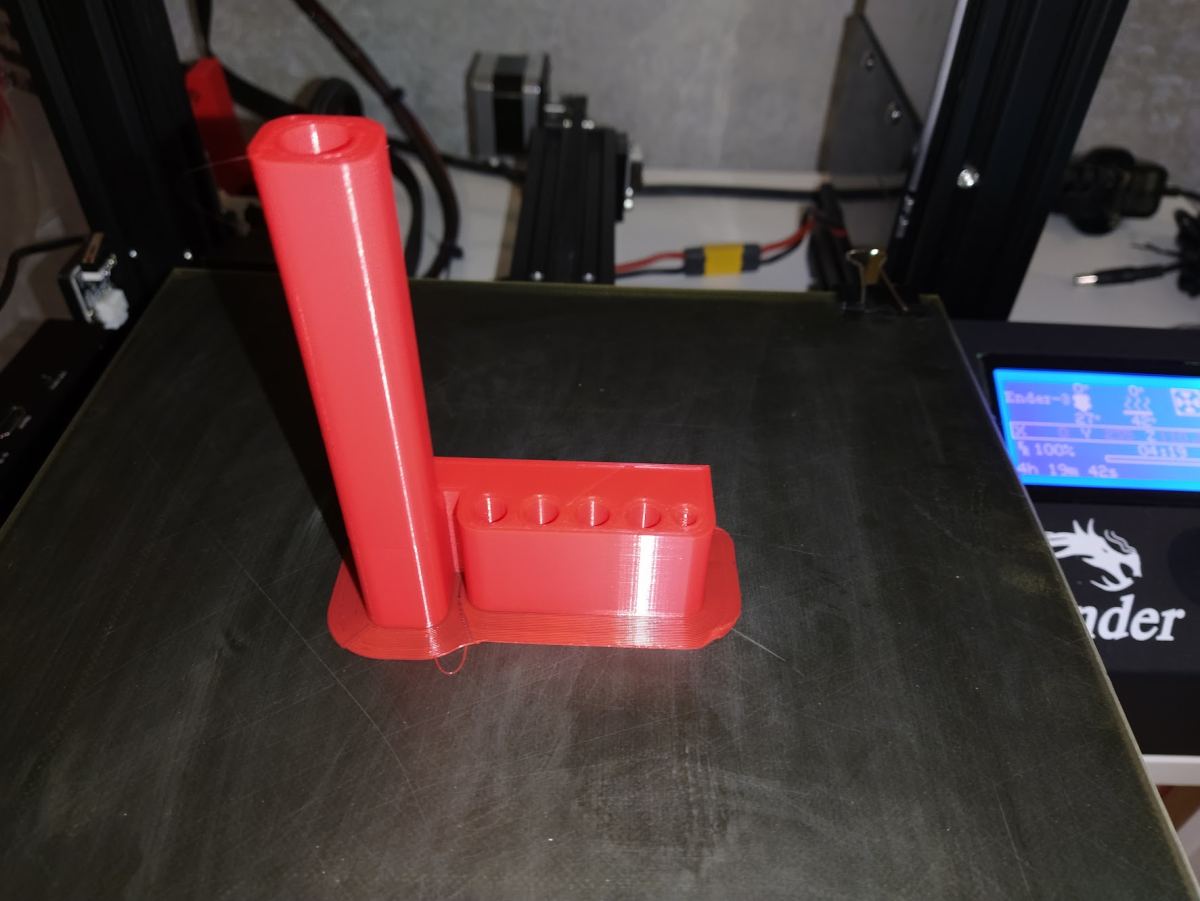

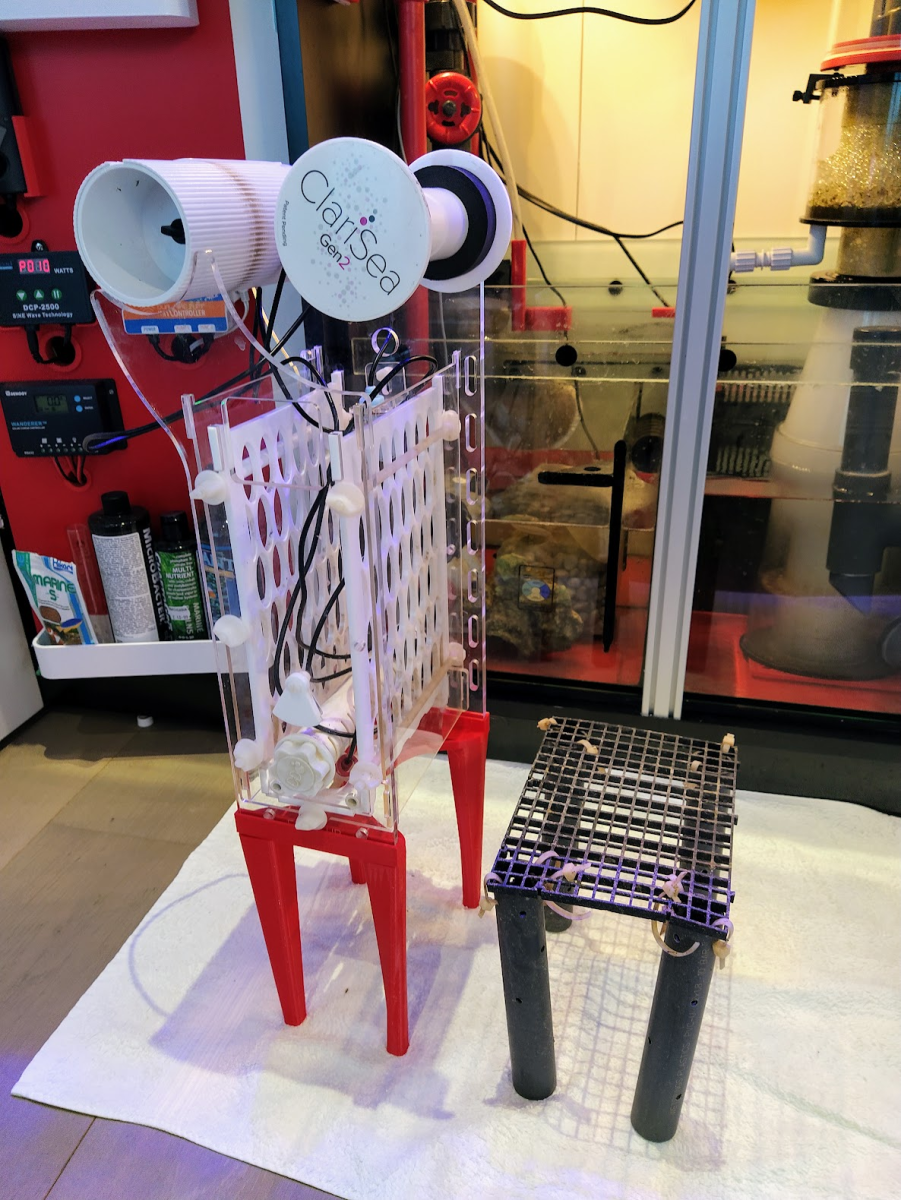

The first was to upgrade the flimsy stand I originally constructed from egg crate and PVC pipe to a 3d printed stand that I designed (https://www.thingiverse.com/thing:5933105):

The new stand is a vast improvement on the old and makes it much easier to take the Clarisea in and out of the sump for cleaning.

Motor cruciform upgrade

The other modification I have made arose from an issue with the used filter fleece bunching up as it got closer to the end of the roll, allowing water to bypass the filter:

This seems to be a fairly common problem and the manufacturer will supply a spacer tube to resolve the issue if you contact them (https://www.theaquariumsolution.com...sk5000-fleece-forming-ridge-centre-dirty-roll). However, while the spacer did stop the roll bunching up, it seemed to put more stress on the motor and resulted in the plastic cruciform, which connects to the motor shaft, breaking as it got towards the end of the first roll after adding the spacer:

The manufacturer sent me a replacement cruciform that has clearly been upgraded to make it stronger and while this did not break, it slipped off the motor shaft as it got towards the end of the roll. I noticed from the D-D website that on the newer Clarisea units, the screw which attaches the cruciform to the motor shaft passes all the way through the shaft rather than merely sitting in a small indentation on the shaft: https://www.theaquariumsolution.com/motor-my-clarisea-looks-it-struggling-pull-fleece-through

My Gen2 came with the v1 cruciform, but the v2 and v3 cruciforms are both designed so that the screw passes through the shaft.

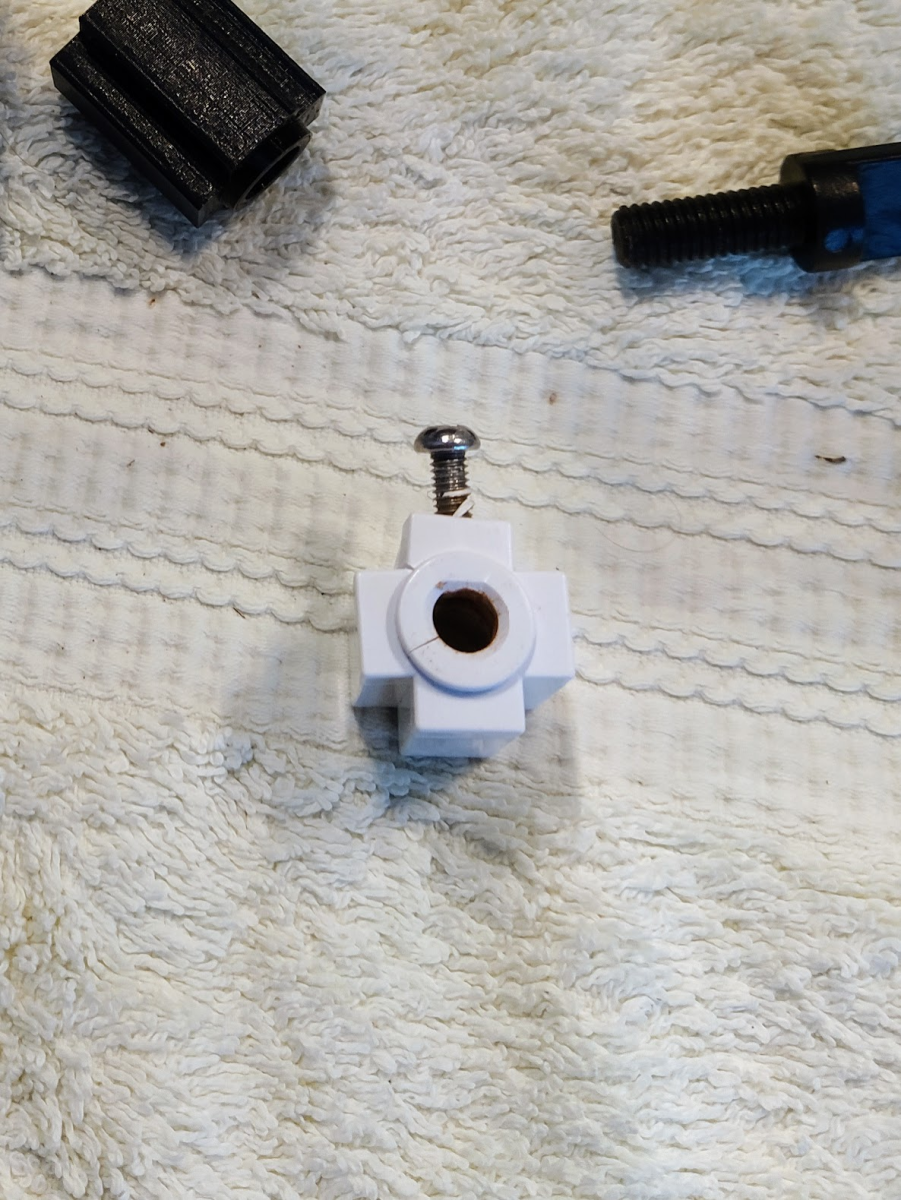

I decided to try to drill a hole through the motor shaft of my Clarisea to match the newer design. I do not have a bench drill, so used my cordless drill, going very slowly and adding small amounts of lubricating oil to prevent the bit being dulled. It took a while, but eventually I managed to drill through the shaft:

With the hole drilled, I could then attach the replacement cruciform to the shaft with a long bolt, which I secured with a nut on the other side for good measure:

Since making this upgrade, I have not had any issues with the motor strugging to pull the fleece through the roller or with the cruciform snapping. It looks like D-D have fixed this issue as standard on the newer Gen3 units.

I made a couple of modications/improvements to my Clarisea SK-5000 over the last couple of years.

Stand

The first was to upgrade the flimsy stand I originally constructed from egg crate and PVC pipe to a 3d printed stand that I designed (https://www.thingiverse.com/thing:5933105):

The new stand is a vast improvement on the old and makes it much easier to take the Clarisea in and out of the sump for cleaning.

Motor cruciform upgrade

The other modification I have made arose from an issue with the used filter fleece bunching up as it got closer to the end of the roll, allowing water to bypass the filter:

This seems to be a fairly common problem and the manufacturer will supply a spacer tube to resolve the issue if you contact them (https://www.theaquariumsolution.com...sk5000-fleece-forming-ridge-centre-dirty-roll). However, while the spacer did stop the roll bunching up, it seemed to put more stress on the motor and resulted in the plastic cruciform, which connects to the motor shaft, breaking as it got towards the end of the first roll after adding the spacer:

The manufacturer sent me a replacement cruciform that has clearly been upgraded to make it stronger and while this did not break, it slipped off the motor shaft as it got towards the end of the roll. I noticed from the D-D website that on the newer Clarisea units, the screw which attaches the cruciform to the motor shaft passes all the way through the shaft rather than merely sitting in a small indentation on the shaft: https://www.theaquariumsolution.com/motor-my-clarisea-looks-it-struggling-pull-fleece-through

My Gen2 came with the v1 cruciform, but the v2 and v3 cruciforms are both designed so that the screw passes through the shaft.

I decided to try to drill a hole through the motor shaft of my Clarisea to match the newer design. I do not have a bench drill, so used my cordless drill, going very slowly and adding small amounts of lubricating oil to prevent the bit being dulled. It took a while, but eventually I managed to drill through the shaft:

With the hole drilled, I could then attach the replacement cruciform to the shaft with a long bolt, which I secured with a nut on the other side for good measure:

Since making this upgrade, I have not had any issues with the motor strugging to pull the fleece through the roller or with the cruciform snapping. It looks like D-D have fixed this issue as standard on the newer Gen3 units.

Touchscreen Controller

I wanted an easy way to control equipment and runs macros on reef-pi without having to pull out my phone and login to the webinterface, so I purchased a small 5" HDMI touchscreen (made by a company called Waveshare) and mounted it alongside the pump controllers:

The mount and cover for the dispay were 3d printed (design here: https://www.thingiverse.com/thing:5933513):

The display runs some software that I wrote called Kivy Reef, which acts as a simplified touchscreen interface to reef-pi. More details are available on my other thread: https://www.reef2reef.com/threads/k...i-announcements-and-discussion-thread.865824/

The display makes it very easy to trigger my water change macro, which turns on/off all the pumps, UV, skimmer and ATO, or turn on/off individual pieces of equipment when I need to do maintenance. It also provides an easy way to quickly check the temperature and pH.

I wanted an easy way to control equipment and runs macros on reef-pi without having to pull out my phone and login to the webinterface, so I purchased a small 5" HDMI touchscreen (made by a company called Waveshare) and mounted it alongside the pump controllers:

The mount and cover for the dispay were 3d printed (design here: https://www.thingiverse.com/thing:5933513):

The display runs some software that I wrote called Kivy Reef, which acts as a simplified touchscreen interface to reef-pi. More details are available on my other thread: https://www.reef2reef.com/threads/k...i-announcements-and-discussion-thread.865824/

The display makes it very easy to trigger my water change macro, which turns on/off all the pumps, UV, skimmer and ATO, or turn on/off individual pieces of equipment when I need to do maintenance. It also provides an easy way to quickly check the temperature and pH.

Miscellaneous – Part 1

I'm getting close to wrapping up this build thread. Here are a few miscellaneous bits and pieces.

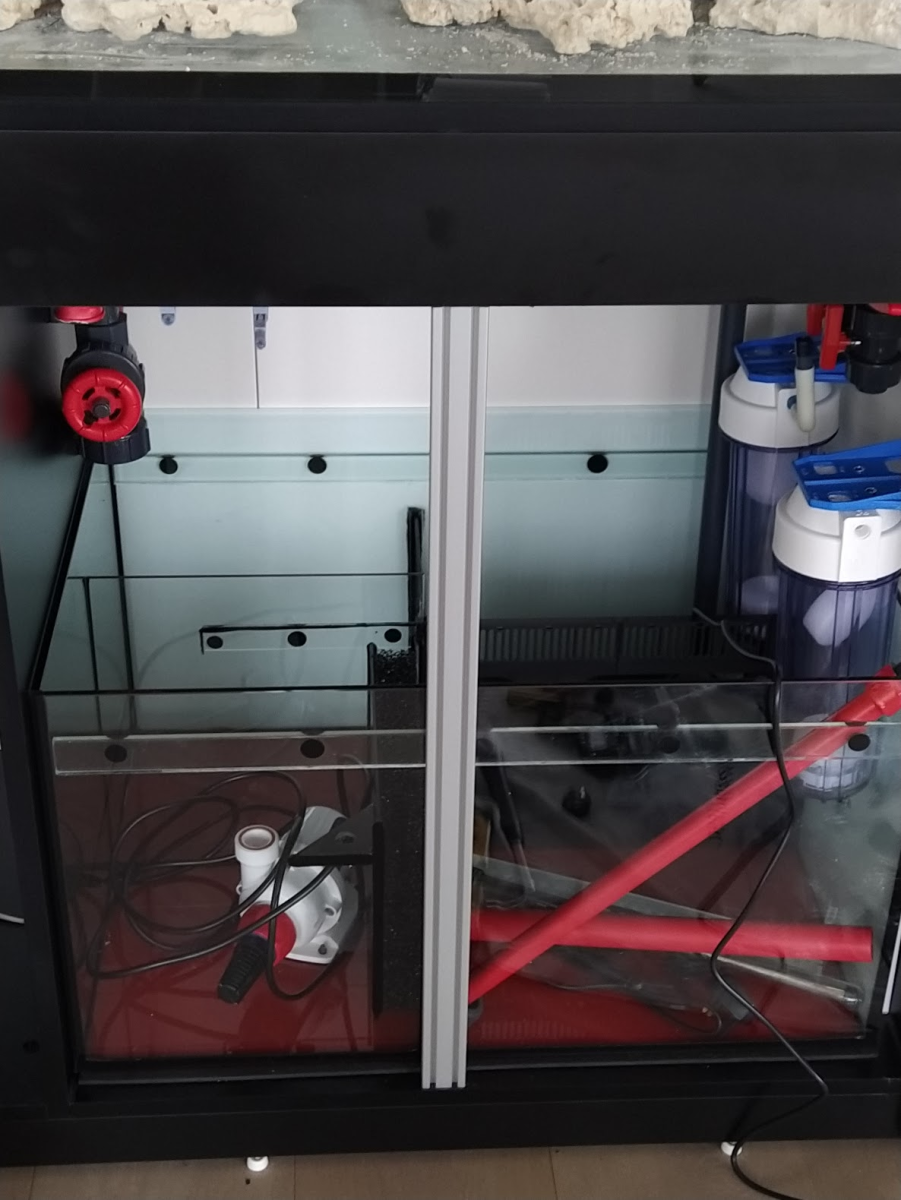

Cabinet Support

After I ordered the tank, details started to emerge about the front seam failure issue on the G1 Reefer 750 XXLs (https://www.reef2reef.com/threads/w...date-design-flaw-confirmed-by-red-sea.638896/) which was identified to be caused by a lack of support over the sump area. While the Peninsula 500 is quite a bit smaller than the 750XXL and does not have any reported issues, out of an abundance of caution I decided to add a vertical support beam using some extruded aluminium before I filled the tank:

Once the tank was filled, I could no longer move the support beam so it is definitely taking some weight and I certainly feel more confident with it installed (particularly as the tank is in an 11th floor apartment, so any leak would be a major issue).

Skimmer Upgrades

I got a deal on eBay for the Reef Octopus automatic neck cleaner for my 150-INT skimmer:

While the neck cleaner certainly improves the performance of the skimmer between cleaning, it makes cleaning significantly more time consuming because of the additional need to clean the neck cleaner itself (which becomes caked in fish poop and has a number of parts that have to be disassembled). Ultimately, I am not sure that it is worth the additional hassle and probably won't run one on my next tank.

I also made a silencer for the outflow pipe of the skimmer using some PVC pipe:

Installed in place:

The silencer works well at reducing the noise made by water running out the skimmer, but does add to the skimmer's bulk.

I'm getting close to wrapping up this build thread. Here are a few miscellaneous bits and pieces.

Cabinet Support

After I ordered the tank, details started to emerge about the front seam failure issue on the G1 Reefer 750 XXLs (https://www.reef2reef.com/threads/w...date-design-flaw-confirmed-by-red-sea.638896/) which was identified to be caused by a lack of support over the sump area. While the Peninsula 500 is quite a bit smaller than the 750XXL and does not have any reported issues, out of an abundance of caution I decided to add a vertical support beam using some extruded aluminium before I filled the tank:

Once the tank was filled, I could no longer move the support beam so it is definitely taking some weight and I certainly feel more confident with it installed (particularly as the tank is in an 11th floor apartment, so any leak would be a major issue).

Skimmer Upgrades

I got a deal on eBay for the Reef Octopus automatic neck cleaner for my 150-INT skimmer:

While the neck cleaner certainly improves the performance of the skimmer between cleaning, it makes cleaning significantly more time consuming because of the additional need to clean the neck cleaner itself (which becomes caked in fish poop and has a number of parts that have to be disassembled). Ultimately, I am not sure that it is worth the additional hassle and probably won't run one on my next tank.

I also made a silencer for the outflow pipe of the skimmer using some PVC pipe:

Installed in place:

The silencer works well at reducing the noise made by water running out the skimmer, but does add to the skimmer's bulk.

Miscellaneous – Part 2

Tank Cover

After one of my first additions to the tank (a small clown) sadly jumped while I was on holiday, I realised I needed a cover for the tank. I ordered a custom polycarbonate mesh lid from a company in the UK with a feeding hatch and cable cutouts:

It looks very clean, although does get covered in salt creep after a while.

Cooling

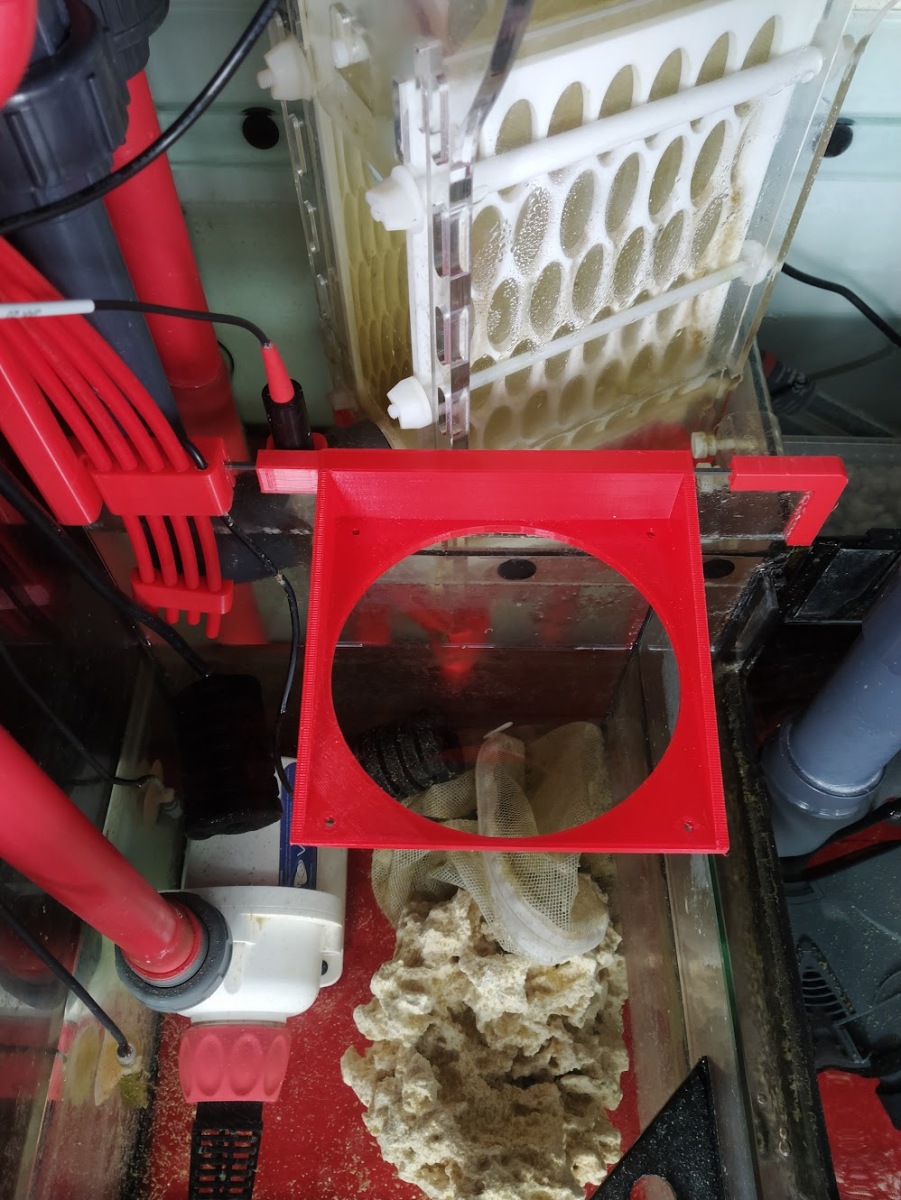

In order to keep the tank cool in the summer, I added a 140mm computer fan over the sump:

This has been sufficient to keep the tank within range in the relatively mild UK summers.

Tool Holder

I 3d printed a small bracket to hold some essential tools in the cabinet – coral feeder, algae scraper and coral tweezers:

Tank Cover

After one of my first additions to the tank (a small clown) sadly jumped while I was on holiday, I realised I needed a cover for the tank. I ordered a custom polycarbonate mesh lid from a company in the UK with a feeding hatch and cable cutouts:

It looks very clean, although does get covered in salt creep after a while.

Cooling

In order to keep the tank cool in the summer, I added a 140mm computer fan over the sump:

This has been sufficient to keep the tank within range in the relatively mild UK summers.

Tool Holder

I 3d printed a small bracket to hold some essential tools in the cabinet – coral feeder, algae scraper and coral tweezers:

DIY Light Bar - Part 1

Apologies for the lack of updates on this build thread. I will try to pick up the pace!

After installing my lights with the stock Red Sea ReefLED mounts, I quickly realised that it would be impossible to hide the cables cleanly on a peninsula tank and I did not like how visible the mounts were through the glass:

Red Sea does offer a hanging mount, but our ceilings are very high and I did not want the hassle of drilling holes in the ceiling. After some research, I came across Deven from ReefDudes' floating light bar using 8020 extruded aluminium:

I decided to make my own version with a slightly different design and ordered the parts online using a cut-to-size service.

Once everything arrived, the first step was to mark and drill holes on the side of the stand to bolt the upright bar to the stand:

In order to ensure that the metal bar does not have direct contact with the tank glass, I designed and 3D printed spacers that slot into the channel in the extrusion:

I also stuck some foam to the spacers that touch the glass.

Here is the upright bar with the spacers and fixings attached:

I also designed and printed some cable clips to keep everything tidy:

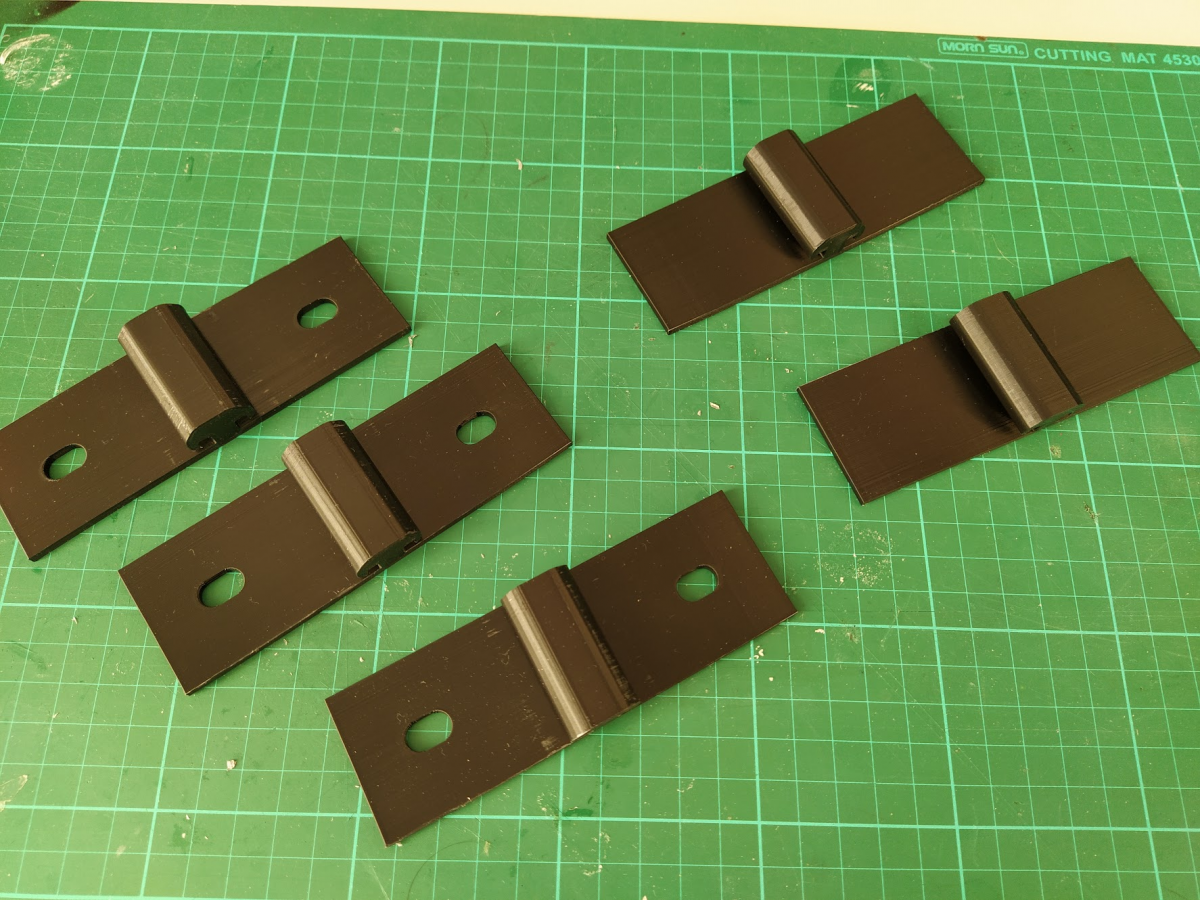

The horizontal bar is attached using angle brackets. For additional security, I decided to use two brackets:

Perflectly level!

That's all for now. In part 2, I will show how I attached the lights to bar with some custom 3D printed mounts.

Hello, as I was doing some research on how to mount the lights, I watched the same video you did and started thinking about how to make the stand but also wanted to attach it to the cabinet and not to the wall. I ran into your post and happens to be that I will be using the same lights so got your mount for them as well. I have some questions my question and would appreciate it if you could help me with:

1. Which 80/20 class bars you got the 30 or the 40? I was thinking of getting the 40 for the vertical one so it can be stronger at holding it and 30 for the horizontal one as might help to be lighter.

2. which supports did get to attach the horizontal one to the vertical stud?

3. would you mind sharing the spacer you made for it as I'm planning to do the same for my tank, I could send you some $$ if you want for them.

4. do you know the size of the screw you use to hold the stud to the cabinet?

5. do you know the lengths of both studs? I have the same peninsula as reefdudes but don't know if the vertical stud should be longer to help hold the weight of the lights

Thank you for all the help!!

Hi @eamena,Hello, as I was doing some research on how to mount the lights, I watched the same video you did and started thinking about how to make the stand but also wanted to attach it to the cabinet and not to the wall. I ran into your post and happens to be that I will be using the same lights so got your mount for them as well. I have some questions my question and would appreciate it if you could help me with:

1. Which 80/20 class bars you got the 30 or the 40? I was thinking of getting the 40 for the vertical one so it can be stronger at holding it and 30 for the horizontal one as might help to be lighter.

2. which supports did get to attach the horizontal one to the vertical stud?

3. would you mind sharing the spacer you made for it as I'm planning to do the same for my tank, I could send you some $$ if you want for them.

4. do you know the size of the screw you use to hold the stud to the cabinet?

5. do you know the lengths of both studs? I have the same peninsula as reefdudes but don't know if the vertical stud should be longer to help hold the weight of the lights

Thank you for all the help!!

Responding to you here publicly as well in case it benefits anyone else.

Here is everything I ordered for my light bar:

| Piece | Item | Quantity | Price | Link |

| Vertical bar | BLACK IR 40X40L | https://www.aluminium-profile.co.uk/black-ir-40x40l-ir02635blk | ||

| Horizontal bar | BLACK IR 40X40L | |||

| Angle support | IR 40X80 BRACKET SET | 2 | 13.08 | https://www.aluminium-profile.co.uk/40x80-bracket-kjn41132 |

| IR 40X80 BRACKET COVER CAP | 2 | 1.58 | https://www.aluminium-profile.co.uk/30x30-bracket-cover-cap-kjn41125 | |

| Connector | STANDARD CONNECTOR ELEMENT | 1 | 0.66 | https://www.aluminium-profile.co.uk/standard-connector-element-pk10-kjn37008 |

| Stand connectors | IR 40X40 ANGLE BRACKET SET | 6 | 21.12 | https://www.aluminium-profile.co.uk/40x40-angle-bracket-set-kjn41115 |

| End caps | 40X40 END CAP | 2 | 1 |

In the end, I used one 40x80 bracket and one 40x40 bracket to attach the horizontal bar to the vertical:

I used 45mm M8 bolts to attach the vertical bar to the cabinet. The vertical bar was 180cm and the horizontal bar was 115cm.

I have uploaded the spacers here: https://www.thingiverse.com/thing:6480673

Good luck with your build!

Similar threads

- Replies

- 4

- Views

- 231

- Replies

- 1

- Views

- 72

New Posts

-

-

-

Albino Crab with purple rings around its pinchers ?

- Latest: ISpeakForTheSeas

-