Let me pose a question to you. What would your aquarium look like if you spent 3-4 years planning it? Would you have a fish room? Would your aquarium be an integral component of your home that blended into your décor in an aesthetically pleasing manner? Would you have a special place for fish towels other than on the floor next to your tank? Follow along with me and I’ll show you what I came up with within the constraints of the layout of my house. For a little background on me and how I got to this point, please see my post in the Meet and Greet Forum here.

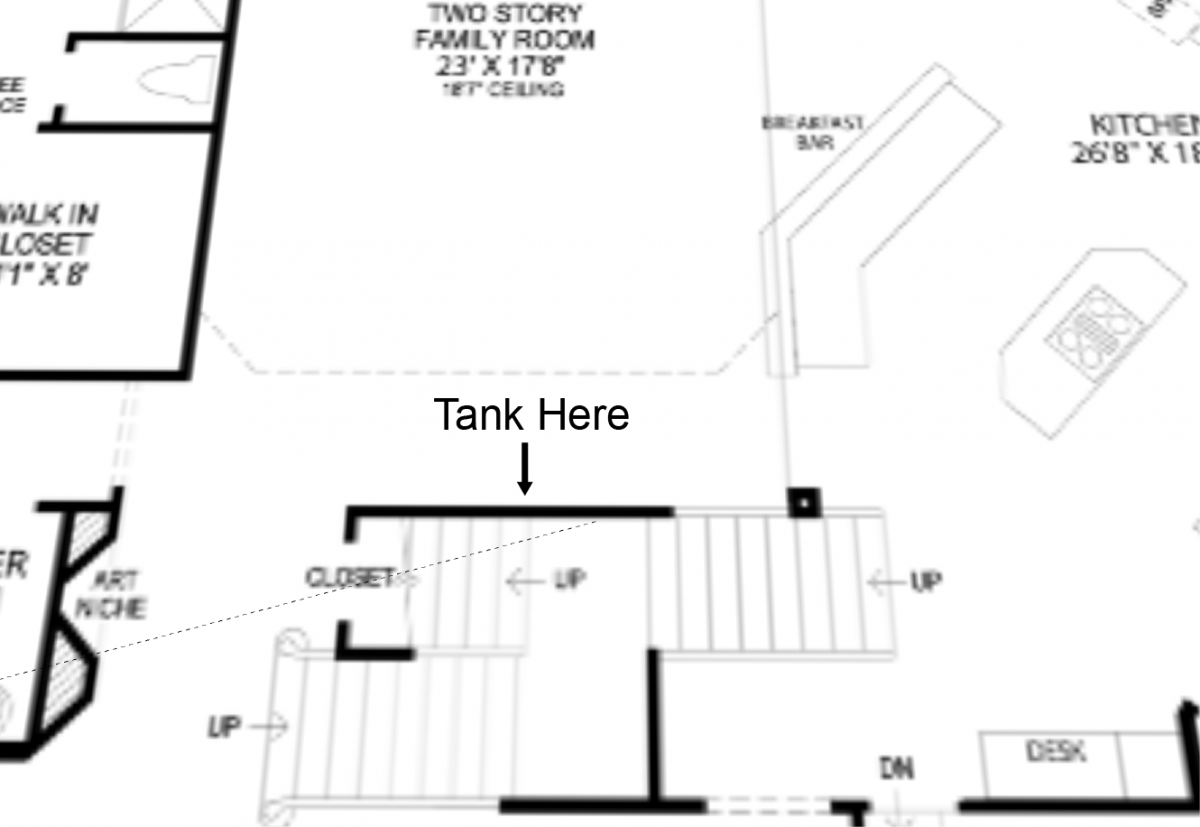

In 2004, my wife and I bought a little plot of land in North Texas and began construction of a house that we hoped to stay in at least until our children were through high school and off to college. We only had one daughter (Age 1) at the time but there was another one planned for the not-to-distant future. Construction of the house was completed 2005, which also happened to correspond to me shutting down my existing aquarium and going without a tank so we could get settled in the new house. During construction of our new home, my wife and I identified a wall in the family room where we could put an aquarium that also allowed access to a closet under the stairs. Can you say fish room?!

While the house was being framed, I had the builder rough-in a 48” (122 cm) header on the chosen wall that would make it easier for me to make an opening whenever I got around to installing an aquarium. Below is a close-up of the header as well as the potential tank wall in context to the remainder of the living space.

Header, close-up.

Header, relationship to living space.

For those of you who may have trouble visualizing the space without sheet rock/dry wall applied, here is a rendering in SketchUp to give you an idea of how that wall would look and the relation to access to the area under the stairs.

Wall for tank placement, viewed from breakfast bar.

Wall for tank placement, closet area access.

As you can see from the pictures, the height of the landing for the stairs precluded a full in-wall tank. This is most apparent in the framing pictures and also meant that the majority of what will become the fish room does not accommodate a normal sized adult in the fully upright position. As a result, I planned for a partially in-wall tank. The idea was to have the tank recessed ~4” (10 cm) into the wall with the remainder jutting out into the room as a traditional aquarium would look. This approach would allow for a deeper tank front-to-back while minimizing protrusion of the tank into the walkway that passes in front of this wall.

Between moving, working, raising a child, having another child, and life in general, it wasn't until 3 years after closing on the house (2008) that I started to seriously contemplate installing an aquarium. It’s not that I didn’t think about it and plan over those three years, it’s just that there was a fair amount of inertia to start a project that would disrupt the major living area of the house and had an absolute requirement NOT to look like my first aquarium (at least on the outside).

The design had to be holistic and take into account not only the needs of the critters, but also the design aesthetic that we had chosen for our home. I also had to pay attention to the fact that I’m going to have in excess of 200 gallons (757 liters) of water hanging out in my house with all the attendant concerns about leaks, humidity, water damage, etc. Likewise, consideration needed to be given to the fact that I really dislike visible equipment when I’m looking into my window on the sea. My design parameters for the tank centered on having pumps and other vital equipment hidden as much as possible. I had 4 Tunze Turbelle 6100s from my previous tank sitting in a box in my garage that would be used for this tank.

Concealing these pumps was a significant consideration when I designed the aquarium. I needed to come up with a way to keep these pumps as unobtrusive as possible. They are effective, but bulky and tend to detract from the aquarium viewing experience. I also wanted to have a Tunze-style wavebox integrated into the tank.

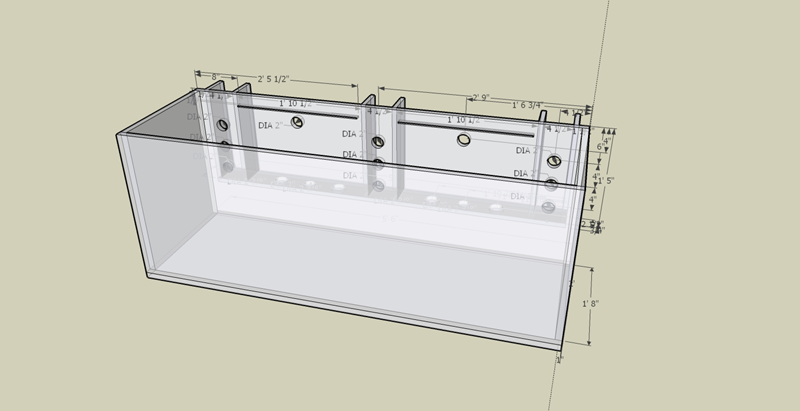

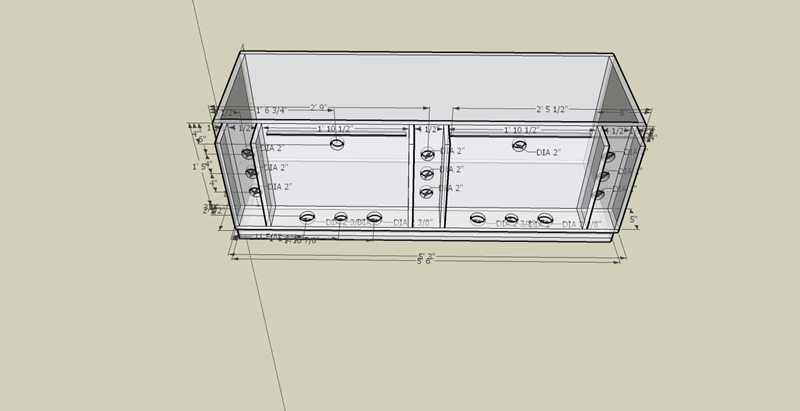

Pictured below is the final aquarium design that I arrived at.

ar

ar

Aquarium, front.

Aquarium, back.

To minimize intrusion, the Streams will be housed behind the back wall in the three "Stream Boxes" (left, center, and right). Each of the three holes in these boxes was cut so that the front port of the Stream could be slid into the hole (see single Stream photo above). I also had caps constructed for these holes, thereby allowing one of the boxes to have two of the three holes plugged to function as a wave box if desired. This approach keeps the Streams out of the viewing area and should not have a significant impact on flow given the nature of propeller pumps.

The tank has dual overflows that were built to be used Herbie-style. The water path to the overflows are ¼” slits to make them less obtrusive and still function to keep any critters from going for a ride into the sump. The holes underneath these slits returns from the sump.

After the plan was completed, I conferred with James (Acrylics on RC) at Envision Acrylics in Oregon and the tank was ordered on 07/1/2008 (a little over a year after my second daughter was born).

I ended up increasing the front-to-back dimensions from 22” (56 cm) to 24” (61 cm) after the plans were sent to James. The final tank dimensions were 66" long x 26" high x 24" deep (168 cm x 66 cm x 61 cm), excluding the overflow/Stream box. The main tank was specified at 1” (25 mm) acrylic to eliminate the need for a center support. The Stream and overflow boxes were constructed of ¾” (19 mm) acrylic with ½” (13 mm) internal acrylic dividers. The back wall of the tank was made from black acrylic, with the remainder being clear.

Given the dimensions and thickness of acrylic used, the tank volume was a little over 146 gallons (553 liters).

Now, you may be asking yourself how I’m going to fit a 66” long tank into a 48” long hole.

Next up…delivery!

Osler

In 2004, my wife and I bought a little plot of land in North Texas and began construction of a house that we hoped to stay in at least until our children were through high school and off to college. We only had one daughter (Age 1) at the time but there was another one planned for the not-to-distant future. Construction of the house was completed 2005, which also happened to correspond to me shutting down my existing aquarium and going without a tank so we could get settled in the new house. During construction of our new home, my wife and I identified a wall in the family room where we could put an aquarium that also allowed access to a closet under the stairs. Can you say fish room?!

While the house was being framed, I had the builder rough-in a 48” (122 cm) header on the chosen wall that would make it easier for me to make an opening whenever I got around to installing an aquarium. Below is a close-up of the header as well as the potential tank wall in context to the remainder of the living space.

Header, close-up.

Header, relationship to living space.

For those of you who may have trouble visualizing the space without sheet rock/dry wall applied, here is a rendering in SketchUp to give you an idea of how that wall would look and the relation to access to the area under the stairs.

Wall for tank placement, viewed from breakfast bar.

Wall for tank placement, closet area access.

As you can see from the pictures, the height of the landing for the stairs precluded a full in-wall tank. This is most apparent in the framing pictures and also meant that the majority of what will become the fish room does not accommodate a normal sized adult in the fully upright position. As a result, I planned for a partially in-wall tank. The idea was to have the tank recessed ~4” (10 cm) into the wall with the remainder jutting out into the room as a traditional aquarium would look. This approach would allow for a deeper tank front-to-back while minimizing protrusion of the tank into the walkway that passes in front of this wall.

Between moving, working, raising a child, having another child, and life in general, it wasn't until 3 years after closing on the house (2008) that I started to seriously contemplate installing an aquarium. It’s not that I didn’t think about it and plan over those three years, it’s just that there was a fair amount of inertia to start a project that would disrupt the major living area of the house and had an absolute requirement NOT to look like my first aquarium (at least on the outside).

The design had to be holistic and take into account not only the needs of the critters, but also the design aesthetic that we had chosen for our home. I also had to pay attention to the fact that I’m going to have in excess of 200 gallons (757 liters) of water hanging out in my house with all the attendant concerns about leaks, humidity, water damage, etc. Likewise, consideration needed to be given to the fact that I really dislike visible equipment when I’m looking into my window on the sea. My design parameters for the tank centered on having pumps and other vital equipment hidden as much as possible. I had 4 Tunze Turbelle 6100s from my previous tank sitting in a box in my garage that would be used for this tank.

Concealing these pumps was a significant consideration when I designed the aquarium. I needed to come up with a way to keep these pumps as unobtrusive as possible. They are effective, but bulky and tend to detract from the aquarium viewing experience. I also wanted to have a Tunze-style wavebox integrated into the tank.

Pictured below is the final aquarium design that I arrived at.

Aquarium, front.

Aquarium, back.

To minimize intrusion, the Streams will be housed behind the back wall in the three "Stream Boxes" (left, center, and right). Each of the three holes in these boxes was cut so that the front port of the Stream could be slid into the hole (see single Stream photo above). I also had caps constructed for these holes, thereby allowing one of the boxes to have two of the three holes plugged to function as a wave box if desired. This approach keeps the Streams out of the viewing area and should not have a significant impact on flow given the nature of propeller pumps.

The tank has dual overflows that were built to be used Herbie-style. The water path to the overflows are ¼” slits to make them less obtrusive and still function to keep any critters from going for a ride into the sump. The holes underneath these slits returns from the sump.

After the plan was completed, I conferred with James (Acrylics on RC) at Envision Acrylics in Oregon and the tank was ordered on 07/1/2008 (a little over a year after my second daughter was born).

I ended up increasing the front-to-back dimensions from 22” (56 cm) to 24” (61 cm) after the plans were sent to James. The final tank dimensions were 66" long x 26" high x 24" deep (168 cm x 66 cm x 61 cm), excluding the overflow/Stream box. The main tank was specified at 1” (25 mm) acrylic to eliminate the need for a center support. The Stream and overflow boxes were constructed of ¾” (19 mm) acrylic with ½” (13 mm) internal acrylic dividers. The back wall of the tank was made from black acrylic, with the remainder being clear.

Given the dimensions and thickness of acrylic used, the tank volume was a little over 146 gallons (553 liters).

Now, you may be asking yourself how I’m going to fit a 66” long tank into a 48” long hole.

Next up…delivery!

Osler