- Joined

- Mar 8, 2019

- Messages

- 19

- Reaction score

- 14

So.. after jerking around with cubes and nano tanks for years because of career, moves, Etc. I have finally been able to cross off a bucket list item: first class 120+ gallon reef tank!

So, before I get into my thoughts so far, here is the equipment list for this build.

Tank

Red Sea Peninsula 650

Equipment

Apex 2016

Reef Octopus Elite 150int

Apex Cor 20 return

Simplicity dc1000 (Algae Scrubber)

Clear Water cw100

Finnex heater

Apex Dos

Tunze ATO

(2) Maxspect 350 gyre

Nyos Torque 1.0

Lights

(3) Radion xr30 g4 pro

Water station

(2) Norwesco 65g upright

Pan world 50px pump with 3/4” Penducter on salt side.

Spectrapure max 90 5 stage plumbed into house main

Misc schedule 80

I am going to try to not go into too much minutiae about packing, unpacking, unboxing, basic assembly etc.. and try to stay focused on my challenges and lessons learned. Hopefully, it will save someone some headache at worst and avoid disaster at best.

Unpacking and Assembly

First, let me say that the quality of the tank and cabinet is top notch. I’ve been running an Elos midi for the last year or so and I can honestly say that the 650 tank itself is on par if not better in some regards than the Elos and the the Red Sea cabinet blows Elos completely out of the water. (No pun intended). All of the Red Sea components are good quality. The tank seams are perfect. The glass has only a very, very minor tint of green when looking down the glass from the top. Everything fits together as perfect as CNC mass produced furniture can and the finish is top notch.

That said...

- Save all of the stainless screws that you need to remove to unpack the tank. There are 3 different sizes and all high quality. I used quite a few of them to mount assorted equipment inside the cabinet and other odds and ends.

- It’s not in any documentation but... key pieces to the cabinet are UNDER the 500lb tank. So you CANNOT build the stand and then move the tank. Do yourself a favor and pick up 4 glass suction handles. Can’t remember what they’re called but I think I paid 40 dollars for 4 from amazon. Hands down, best 40 bucks I have spent in this hobby.

- IMPORTANT. The tank has plastic bulkheads that are pre installed and hang below the bottom of the tank about 1/4 inch. So... when you are moving the tank to get to the cabinet pieces DO NOT drag the tank or put it on the garage floor or house flooring. Tempered glass is strong but brittle. My solution was to have my wife and I basically pick the bulkhead side up with the suction handles and slide it over so the bulkhead fittings we’re hanging over the side of the shipping pallet.

- The instructions are a big ambiguous about how to assemble the stand based on choosing left side or right side doors. I screwed up the base rails and had to backtrack to get it right. Only advice here is to make sure you can see the pre drilled holes on the top rail and bottom rail as you’re looking through the “doors”. These holes are where you attach the panels that make up the “front” of the tank.

- The lock nuts on the leveling feet should be removed before screwing them in. They really

aren’t necessary, lowers the tank a little to get rid of that nasty gap and makes leveling a whole lot easier. Also, screw the feet all the way in. Again, no reason to leave room for adjustment “up”. You will most certainly introduce “pilot induced oscillation “ if you leave more than one axis for adjusting 50 dang screw levelers.

-The doors, oh, the doors. The instructions say “slide and click the doors into place.” Lol. Not sure about the other reefer series but for the 650, the geometry on the door hinges is weird. It kind of lifts forward and out. Not sure how to explain it but long story short.... I could not for the life of me get the doors to slide and click. My solution was to attach the hinges to the cabinet and leave the door off. I put the hinge in the closed position, lined up the door and seated the hinge inside the door hole and then screw the door side in. Lol. I’m probably a dum dum and missing something stupid. IDK. Would love to hear if anyone cracked the code on these.

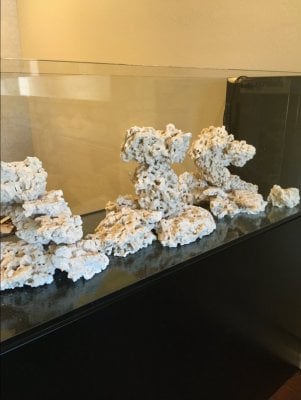

That’s it for now but I will follow up with my rockscape challenges and solutions along with some more pics. Didn’t think anyone would be interested in seeing a big black box so not too many of the cabinet without the tank.

I would be happy to answer any questions anyone has about the build, dimensions or whatever related to the peninsula 650.

So, before I get into my thoughts so far, here is the equipment list for this build.

Tank

Red Sea Peninsula 650

Equipment

Apex 2016

Reef Octopus Elite 150int

Apex Cor 20 return

Simplicity dc1000 (Algae Scrubber)

Clear Water cw100

Finnex heater

Apex Dos

Tunze ATO

(2) Maxspect 350 gyre

Nyos Torque 1.0

Lights

(3) Radion xr30 g4 pro

Water station

(2) Norwesco 65g upright

Pan world 50px pump with 3/4” Penducter on salt side.

Spectrapure max 90 5 stage plumbed into house main

Misc schedule 80

I am going to try to not go into too much minutiae about packing, unpacking, unboxing, basic assembly etc.. and try to stay focused on my challenges and lessons learned. Hopefully, it will save someone some headache at worst and avoid disaster at best.

Unpacking and Assembly

First, let me say that the quality of the tank and cabinet is top notch. I’ve been running an Elos midi for the last year or so and I can honestly say that the 650 tank itself is on par if not better in some regards than the Elos and the the Red Sea cabinet blows Elos completely out of the water. (No pun intended). All of the Red Sea components are good quality. The tank seams are perfect. The glass has only a very, very minor tint of green when looking down the glass from the top. Everything fits together as perfect as CNC mass produced furniture can and the finish is top notch.

That said...

- Save all of the stainless screws that you need to remove to unpack the tank. There are 3 different sizes and all high quality. I used quite a few of them to mount assorted equipment inside the cabinet and other odds and ends.

- It’s not in any documentation but... key pieces to the cabinet are UNDER the 500lb tank. So you CANNOT build the stand and then move the tank. Do yourself a favor and pick up 4 glass suction handles. Can’t remember what they’re called but I think I paid 40 dollars for 4 from amazon. Hands down, best 40 bucks I have spent in this hobby.

- IMPORTANT. The tank has plastic bulkheads that are pre installed and hang below the bottom of the tank about 1/4 inch. So... when you are moving the tank to get to the cabinet pieces DO NOT drag the tank or put it on the garage floor or house flooring. Tempered glass is strong but brittle. My solution was to have my wife and I basically pick the bulkhead side up with the suction handles and slide it over so the bulkhead fittings we’re hanging over the side of the shipping pallet.

- The instructions are a big ambiguous about how to assemble the stand based on choosing left side or right side doors. I screwed up the base rails and had to backtrack to get it right. Only advice here is to make sure you can see the pre drilled holes on the top rail and bottom rail as you’re looking through the “doors”. These holes are where you attach the panels that make up the “front” of the tank.

- The lock nuts on the leveling feet should be removed before screwing them in. They really

aren’t necessary, lowers the tank a little to get rid of that nasty gap and makes leveling a whole lot easier. Also, screw the feet all the way in. Again, no reason to leave room for adjustment “up”. You will most certainly introduce “pilot induced oscillation “ if you leave more than one axis for adjusting 50 dang screw levelers.

-The doors, oh, the doors. The instructions say “slide and click the doors into place.” Lol. Not sure about the other reefer series but for the 650, the geometry on the door hinges is weird. It kind of lifts forward and out. Not sure how to explain it but long story short.... I could not for the life of me get the doors to slide and click. My solution was to attach the hinges to the cabinet and leave the door off. I put the hinge in the closed position, lined up the door and seated the hinge inside the door hole and then screw the door side in. Lol. I’m probably a dum dum and missing something stupid. IDK. Would love to hear if anyone cracked the code on these.

That’s it for now but I will follow up with my rockscape challenges and solutions along with some more pics. Didn’t think anyone would be interested in seeing a big black box so not too many of the cabinet without the tank.

I would be happy to answer any questions anyone has about the build, dimensions or whatever related to the peninsula 650.