Full disclosure, I barely know what I'm doing, but after sleuthing the forums I've clobbered something together that works for me.

Parts used:

2x Phlizon 165W Dimmable Full Spectrum Aquarium LED Lights (No WiFi, just dumb lights)

Raspberry pi 4B

Raspberry Pi Prototyping Board HAT by MakerSpot

LM2596 Buck Converter

22 AWG wire

Old Dell Laptop power supplies that got sacrificed for the project (19.5V / 3.34A)

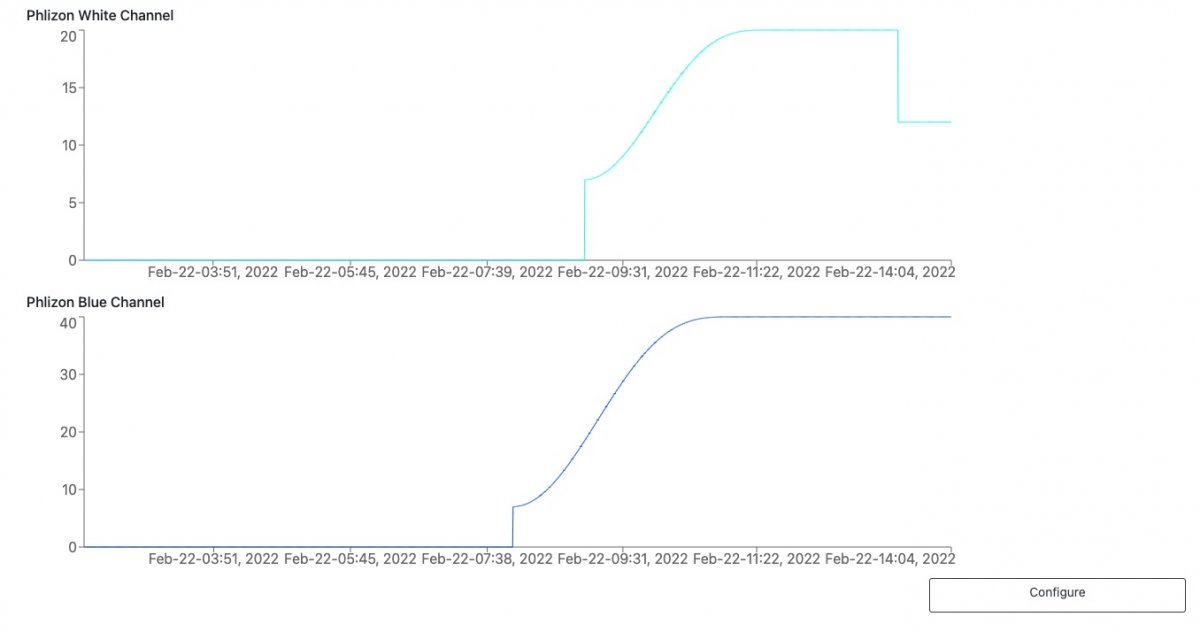

The reason for the project was to gain control of the individual channels, as well as be able to ramp up / down the channels individually on a schedule. I was turning the lights on (both blue and white) at the same time without ramp time with a smart outlet (I'm still using the smart outlet, read below).

I did a poor job of taking pictures during the build, but I'll share what I have.

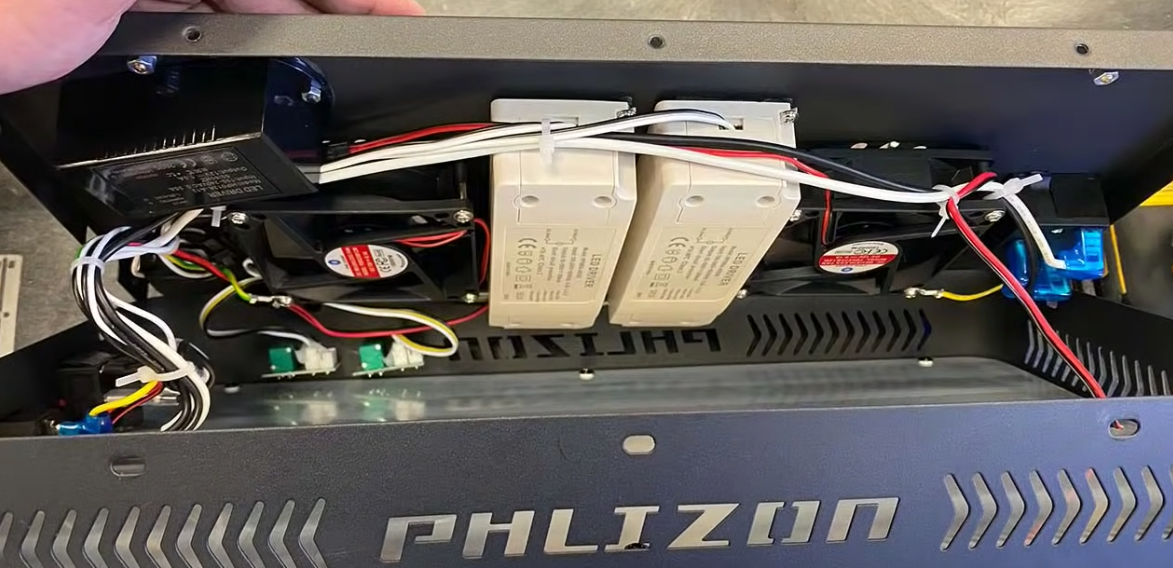

The internals (credit to BRS Black Box LED Battle Royale as I didnt snap a pic while working on it):

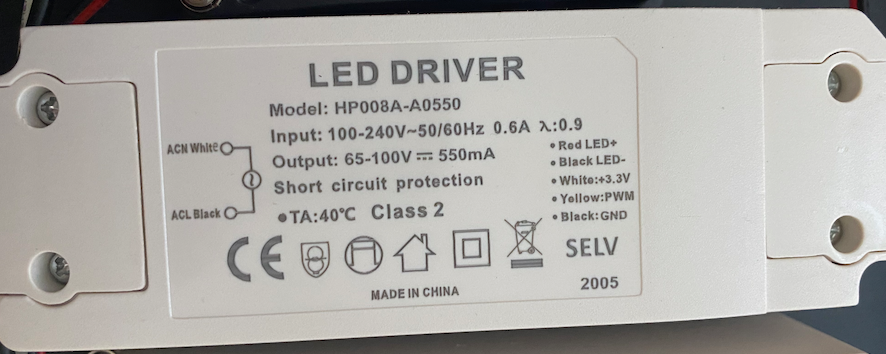

The Blue and White channels are controlled by two of these:

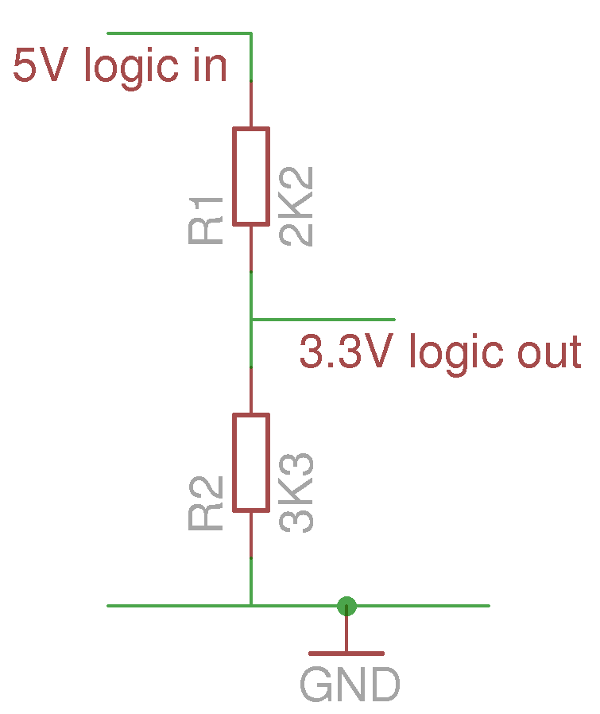

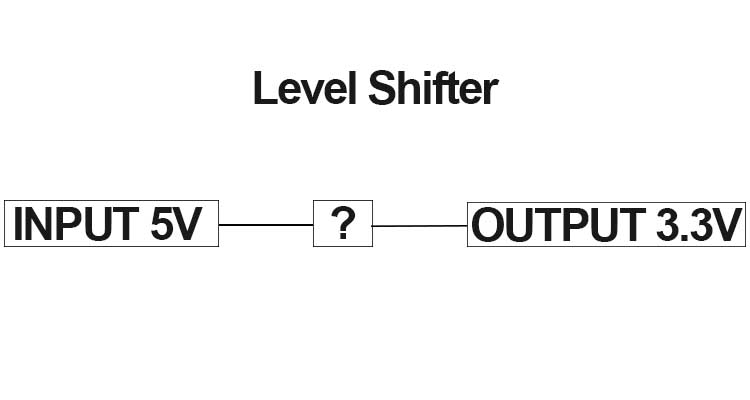

Conveniently, they are PWM and 3.3V.

I left the main power to the drivers as is, and wired the 3.3V, PWM and GND for the White Channel drivers to GPIO 18. and The same for the Blue Channel drivers to GPIO 19.

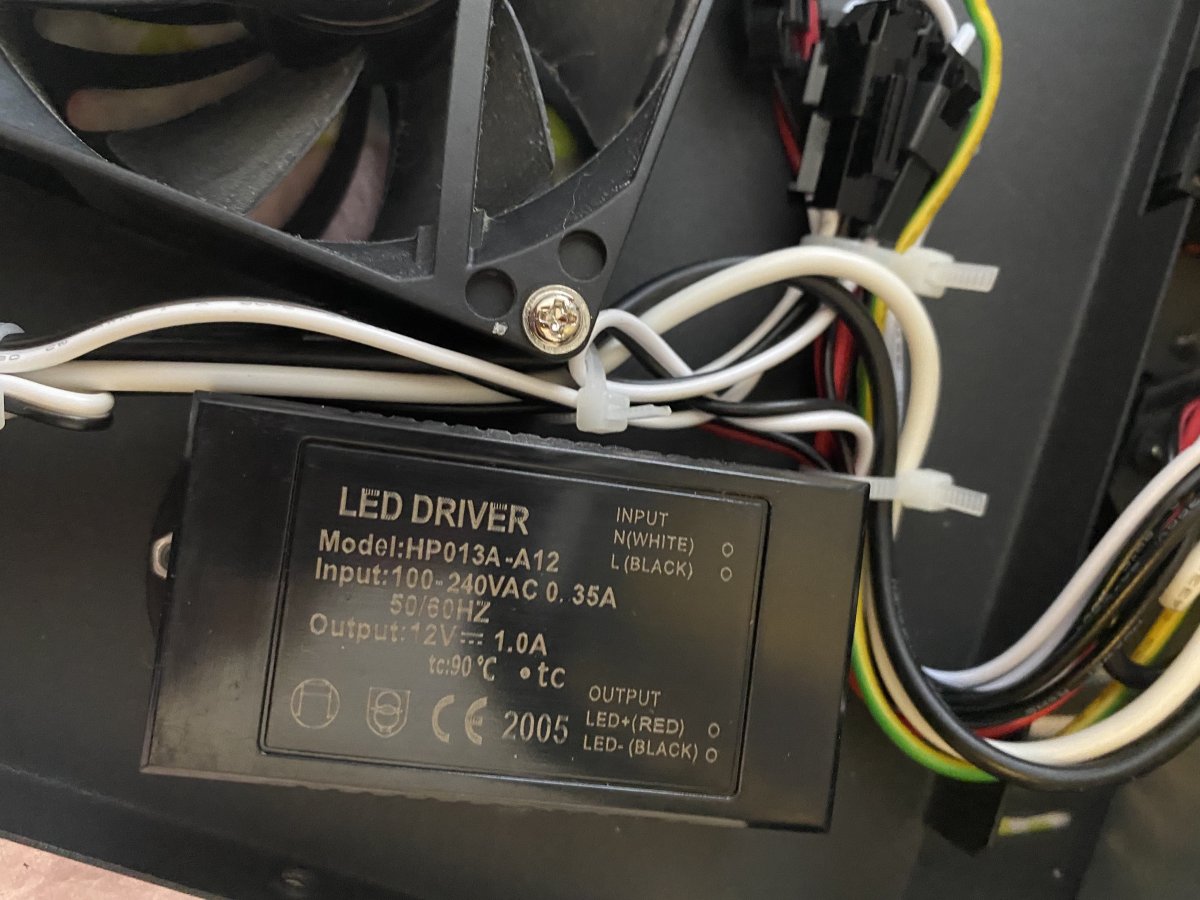

The main hitch I ran into is that the fans are controlled separately from the lights by this 12V driver. So even with the LEDs off, the fans spin away happily.

My ghetto solution right now is to use a smart outlet and turn the lights on / off just before the ramp-up and ramp-down timers come on.

Finished Product:

I've had this running for just about a week, and it's been solid. I need to 3D print a larger case for the Pi, and maybe a little case for the buck converter, but other than that I'm pretty happy with it.

Parts used:

2x Phlizon 165W Dimmable Full Spectrum Aquarium LED Lights (No WiFi, just dumb lights)

Raspberry pi 4B

Raspberry Pi Prototyping Board HAT by MakerSpot

LM2596 Buck Converter

22 AWG wire

Old Dell Laptop power supplies that got sacrificed for the project (19.5V / 3.34A)

The reason for the project was to gain control of the individual channels, as well as be able to ramp up / down the channels individually on a schedule. I was turning the lights on (both blue and white) at the same time without ramp time with a smart outlet (I'm still using the smart outlet, read below).

I did a poor job of taking pictures during the build, but I'll share what I have.

The internals (credit to BRS Black Box LED Battle Royale as I didnt snap a pic while working on it):

The Blue and White channels are controlled by two of these:

Conveniently, they are PWM and 3.3V.

I left the main power to the drivers as is, and wired the 3.3V, PWM and GND for the White Channel drivers to GPIO 18. and The same for the Blue Channel drivers to GPIO 19.

The main hitch I ran into is that the fans are controlled separately from the lights by this 12V driver. So even with the LEDs off, the fans spin away happily.

My ghetto solution right now is to use a smart outlet and turn the lights on / off just before the ramp-up and ramp-down timers come on.

Finished Product:

I've had this running for just about a week, and it's been solid. I need to 3D print a larger case for the Pi, and maybe a little case for the buck converter, but other than that I'm pretty happy with it.