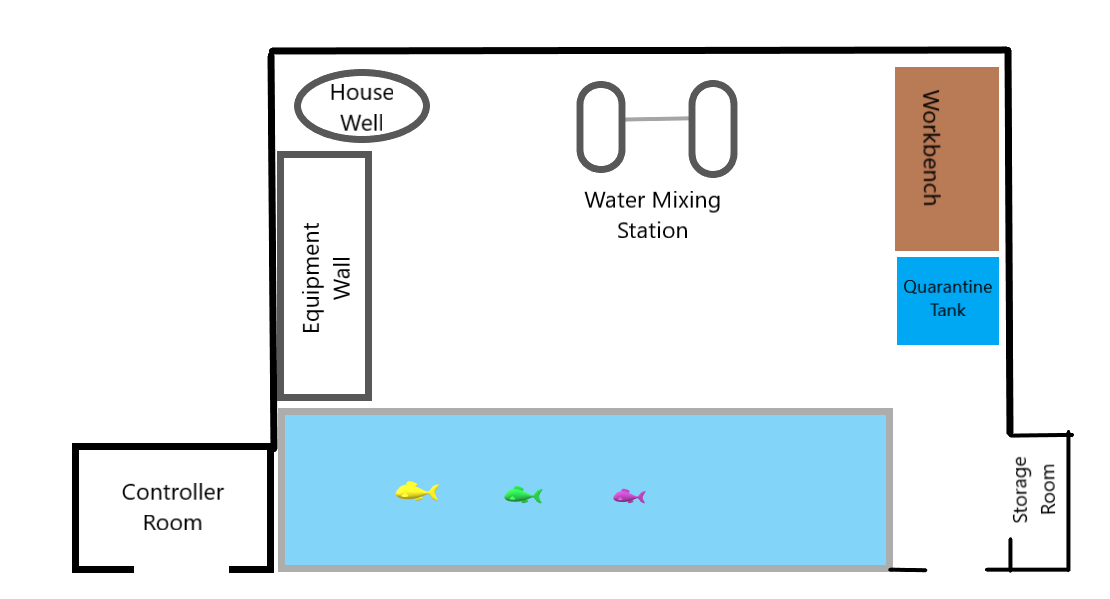

Tank Room Layout

Now that all the tank plumbing is installed and tested, I can turn my attention to the installation of all the equipment. Like many others that have done a new tank build, one of the biggest challenges we all face is how to maximize the available working space to fit all the equipment, controllers, water mixing station, quarantine/frag tanks etc. At the bottom of this post, I've included a very simple drawing that shows the reef tank placement and how I'm going to try and maximize the space for all my equipment. My overall main room available floor space is: 10'L x13'W (this includes the space used by the tank: 96"L x 34"W x 26"H) . Additionally, there is a smaller room for the controller equipment.

Here is a list of all the equipment that needs to be installed:

- 1 BRS 7 Stage RO Sytsem

- 1 Aquatec RO Booster Pump

- 1 57 Watt Aqua Ultraviolet UV Sterilizer

- 1 BRS Carbon Reactor - Deluxe

- 1 BRS GFO Reactor - Deluxe

- 1 BRS Air Filter (ozone generator)

- 1 Apex Controller Head Unit

- 2 Apex 832 Energy Bars

- 1 Apex Automatic Feeding System

- 1 Apex Display Module

- 3 Apex Dosing Fluid Metering Systems

- 2 Apex Dual Reservoir Systems

- 1 Apex Trident Water Analyzer

- 2 Abyzz A200 Controllers

- 1 Bubble King Supermarin 250 Protein Skimmer Controller

- 2 Aqua Logic Digital Temperature Controllers

- 2 Ecotech Vortech MP60 Controllers and leave room for possibly two more controllers (future expansion, depending on long term water flow requirements)

- 1 Red Octopus Various-8 Controller (used for reactors and UV light and potential future chiller)

- 2 65 Gallon Water Storage Tanks along with one Sicce Syncra 7.0 Controller Pump for mixing saltwater and pumping saltwater to MT

- Wall space for one large display computer tablet (probably going to get a 20" tablet) to use with Apex System

- 1 40G Quarantine Tank (24"L x 20"W)

- 1 Workbench (60"L x 24"W). Don't know what I'd do without a workbench area. This bench has been a work-horse throughout the build project

In my next post I'll show you pics on how my installation is coming along for all of this equipment. Here is the drawing that shows the layout of the overall room space.

Now that all the tank plumbing is installed and tested, I can turn my attention to the installation of all the equipment. Like many others that have done a new tank build, one of the biggest challenges we all face is how to maximize the available working space to fit all the equipment, controllers, water mixing station, quarantine/frag tanks etc. At the bottom of this post, I've included a very simple drawing that shows the reef tank placement and how I'm going to try and maximize the space for all my equipment. My overall main room available floor space is: 10'L x13'W (this includes the space used by the tank: 96"L x 34"W x 26"H) . Additionally, there is a smaller room for the controller equipment.

Here is a list of all the equipment that needs to be installed:

- 1 BRS 7 Stage RO Sytsem

- 1 Aquatec RO Booster Pump

- 1 57 Watt Aqua Ultraviolet UV Sterilizer

- 1 BRS Carbon Reactor - Deluxe

- 1 BRS GFO Reactor - Deluxe

- 1 BRS Air Filter (ozone generator)

- 1 Apex Controller Head Unit

- 2 Apex 832 Energy Bars

- 1 Apex Automatic Feeding System

- 1 Apex Display Module

- 3 Apex Dosing Fluid Metering Systems

- 2 Apex Dual Reservoir Systems

- 1 Apex Trident Water Analyzer

- 2 Abyzz A200 Controllers

- 1 Bubble King Supermarin 250 Protein Skimmer Controller

- 2 Aqua Logic Digital Temperature Controllers

- 2 Ecotech Vortech MP60 Controllers and leave room for possibly two more controllers (future expansion, depending on long term water flow requirements)

- 1 Red Octopus Various-8 Controller (used for reactors and UV light and potential future chiller)

- 2 65 Gallon Water Storage Tanks along with one Sicce Syncra 7.0 Controller Pump for mixing saltwater and pumping saltwater to MT

- Wall space for one large display computer tablet (probably going to get a 20" tablet) to use with Apex System

- 1 40G Quarantine Tank (24"L x 20"W)

- 1 Workbench (60"L x 24"W). Don't know what I'd do without a workbench area. This bench has been a work-horse throughout the build project

In my next post I'll show you pics on how my installation is coming along for all of this equipment. Here is the drawing that shows the layout of the overall room space.