Wife involvement.....at least I can blame someone else!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RFBF's 90 Gallon Déjà vu All Over Again

- Build Thread

- Thread starter redfishbluefish

- Start date

- Tagged users None

Better than the 1st version....atleast i think it is. Are you gonna putty it up? Or go with plastic dowels for the support?Wife involvement.....at least I can blame someone else!

Btw, my wife is the one who aqua-scaped my tank.....no shame in it my friend

Thanks for the reply Marcus....I'm not good at doing this kind of artsy stuff....and I've got to get this rock wet...so it's going to be what it's going to be. Here's another variation:

As far as actually building, my preference is simply using plastic hanger pieces with no concrete/epoxy, if I can get away with it. This way it's easy to dismantle, if needed.

As far as actually building, my preference is simply using plastic hanger pieces with no concrete/epoxy, if I can get away with it. This way it's easy to dismantle, if needed.

Almost Ready to Move the Tank/Stand Back into Position

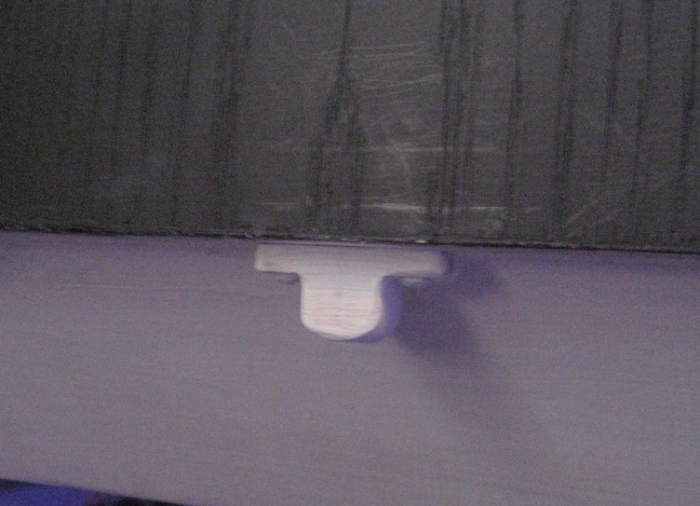

Plumbing is done! But before moving the tank and stand back into position I wanted to do a couple things on the backside. One of the things that had bugged me over the years were the wires on the backside of the stand that simply drooped along the back of the stand. I know, no one could see it, but it still bugged me. To fix this I made plastic hooks to hold the wires. I first made two....and then a third....and finally a fourth. These were simply made by cutting a short piece of 1 inch PVC and putting a cut in the pipe. Half the pipe was then heated with a heat gun for about a minute and then using a small scrape of wood, pressed against a piece of plate steel.

These were roughed up with a piece of sandpaper and siliconed to the back of the tank. Here they are being held by a piece of tape until the silicone cures a bit.

Plumbing is done! But before moving the tank and stand back into position I wanted to do a couple things on the backside. One of the things that had bugged me over the years were the wires on the backside of the stand that simply drooped along the back of the stand. I know, no one could see it, but it still bugged me. To fix this I made plastic hooks to hold the wires. I first made two....and then a third....and finally a fourth. These were simply made by cutting a short piece of 1 inch PVC and putting a cut in the pipe. Half the pipe was then heated with a heat gun for about a minute and then using a small scrape of wood, pressed against a piece of plate steel.

These were roughed up with a piece of sandpaper and siliconed to the back of the tank. Here they are being held by a piece of tape until the silicone cures a bit.

Had fun making the wire hangers above. Could have easily purchased hangers, but the satisfaction of DIY'ing is so well worth the half hour to make these, and a bit more time to silicone the hangers to the tank.

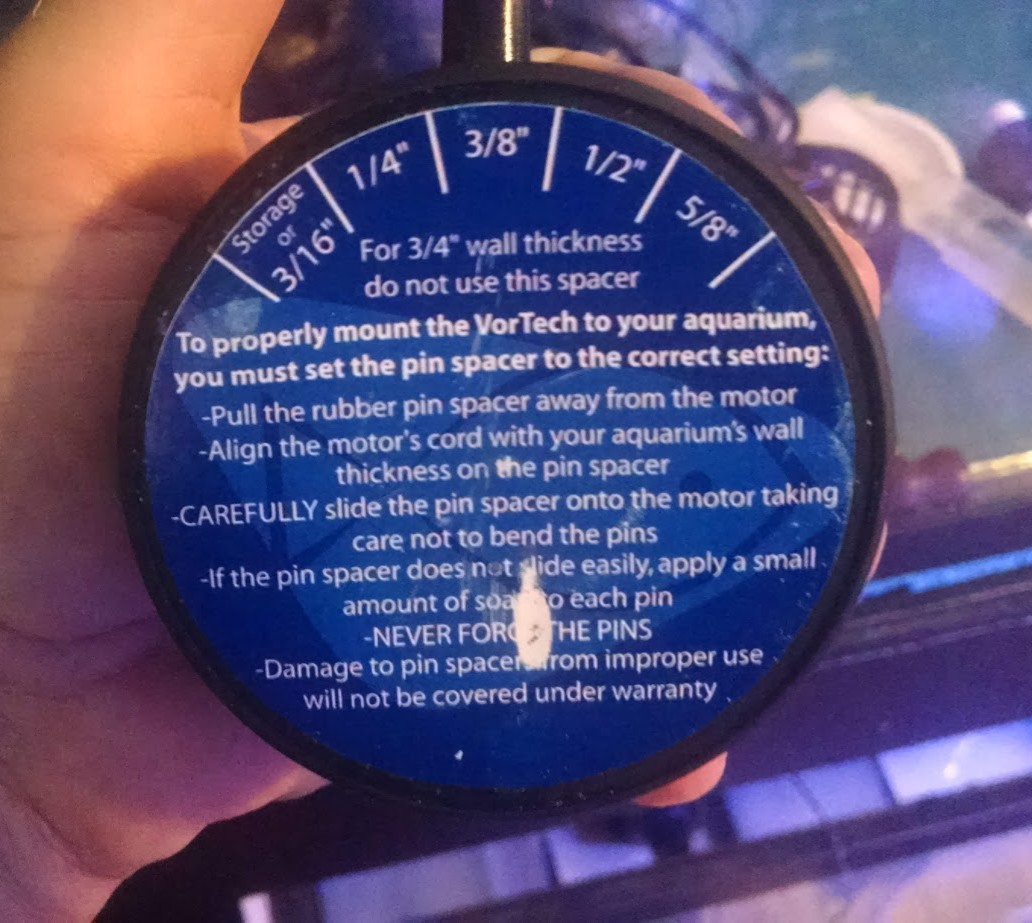

Now all I need to do is pull the wires off three Vortech controllers to re-trace them through the hangers, set the old MP40's to 3/8 inch glass, and I'm done. Maybe another hour.....NOT!

Changing the thickness for three of the MP40's was a breeze, while one took almost two hours to get the three prongs of the spacers to fit. Had to get one of my small round files to file the holes until the prongs fit. And that's using lubricant as well. Now all set for 3/8 inch thickness.

Also readjusted the screws holding the power strip I keep on the far side of the tank..,

I think the only thing left before moving the tank in place is to lube the rubber parts with Leslie's lube.

Now all I need to do is pull the wires off three Vortech controllers to re-trace them through the hangers, set the old MP40's to 3/8 inch glass, and I'm done. Maybe another hour.....NOT!

Changing the thickness for three of the MP40's was a breeze, while one took almost two hours to get the three prongs of the spacers to fit. Had to get one of my small round files to file the holes until the prongs fit. And that's using lubricant as well. Now all set for 3/8 inch thickness.

Also readjusted the screws holding the power strip I keep on the far side of the tank..,

I think the only thing left before moving the tank in place is to lube the rubber parts with Leslie's lube.

reef lover

It's a reef thing....

View Badges

Excellence Award

Reef Tank 365

Hudson Valley Reef Keepers

Hospitality Award

518 Reefers

My Tank Thread

Nice!

Tank/Stand Back Up Against the Wall

Jacked up the stand/tank and pivoted it back into position.

The pivot point must have been slightly different from when I moved it out, because the stand was now about an inch and a half shifted to the right. I put my butt up against the end of the stand and nudged it that back that 1 1/2. Dropped it down from the jack, and done!

Rock coming in tomorrow, weather permitting.

Jacked up the stand/tank and pivoted it back into position.

The pivot point must have been slightly different from when I moved it out, because the stand was now about an inch and a half shifted to the right. I put my butt up against the end of the stand and nudged it that back that 1 1/2. Dropped it down from the jack, and done!

Rock coming in tomorrow, weather permitting.

- Joined

- Feb 21, 2017

- Messages

- 497

- Reaction score

- 248

Tank/Stand Back Up Against the Wall

Jacked up the stand/tank and pivoted it back into position.

The pivot point must have been slightly different from when I moved it out, because the stand was now about an inch and a half shifted to the right. I put my butt up against the end of the stand and nudged it that back that 1 1/2. Dropped it down from the jack, and done!

Rock coming in tomorrow, weather permitting.

Getting closer to get it wet buddy!!!!!

The Cure has Begun!

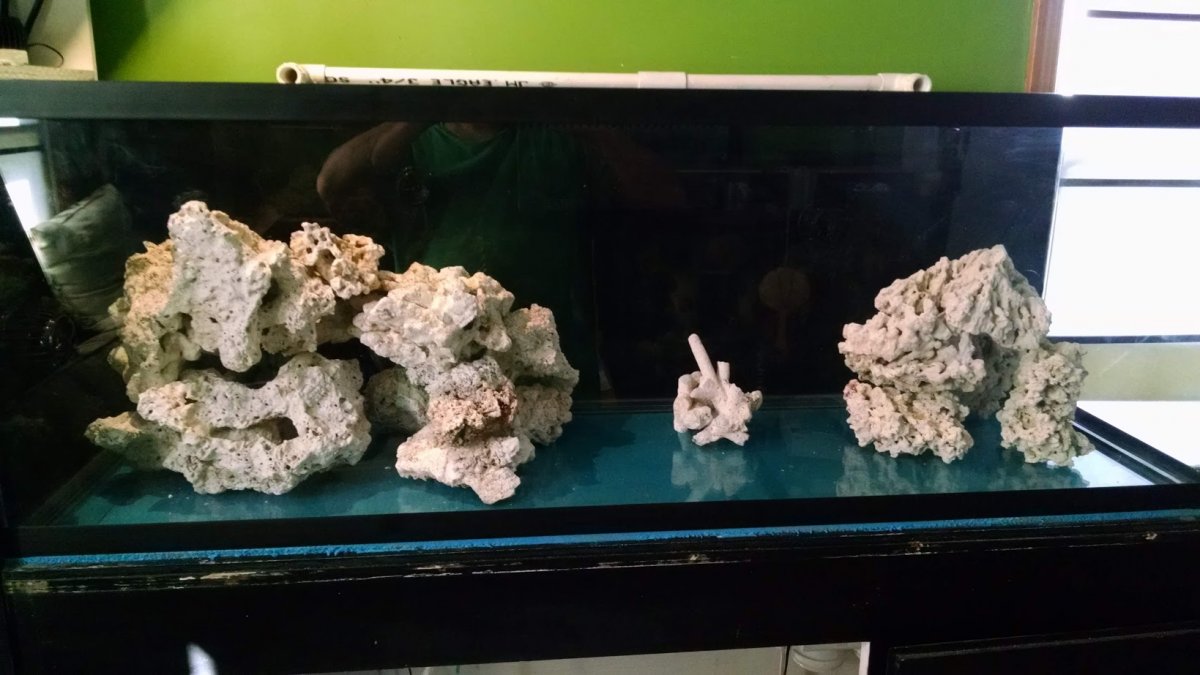

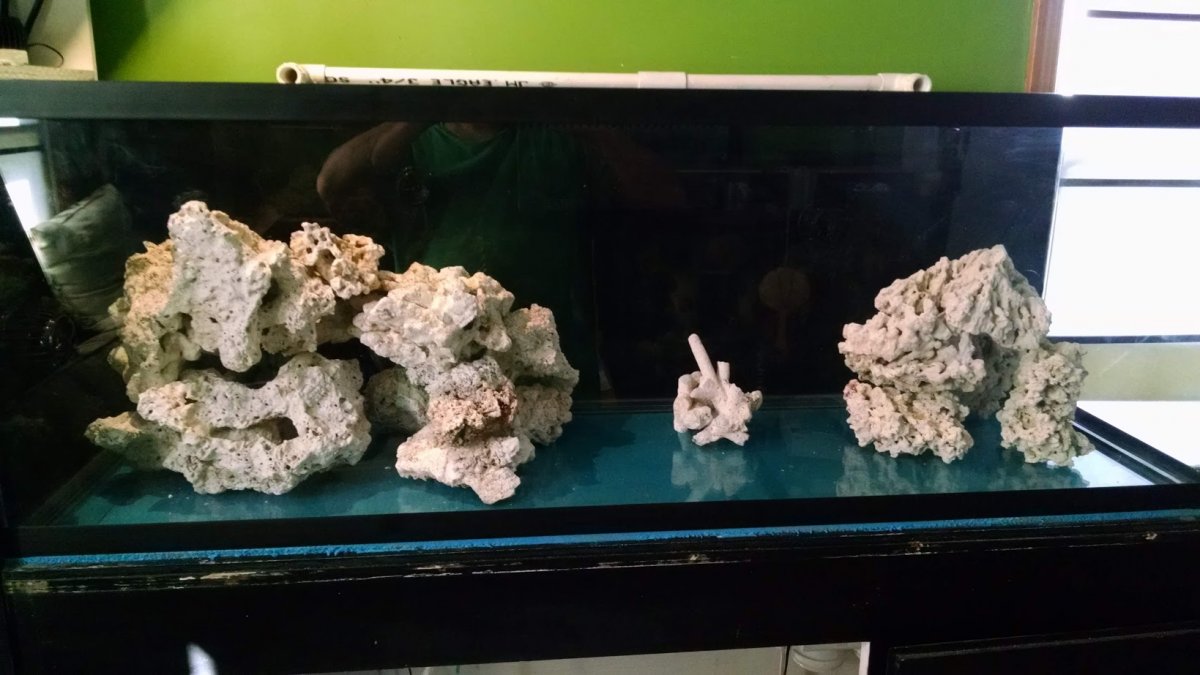

Rock went into the tank....still not happy, but not waiting any longer.

First 50 gallons of water.....RO/DI running now making more....still playing with rock:

Rock went into the tank....still not happy, but not waiting any longer.

First 50 gallons of water.....RO/DI running now making more....still playing with rock:

- Joined

- Feb 21, 2017

- Messages

- 497

- Reaction score

- 248

The Cure has Begun!

Rock went into the tank....still not happy, but not waiting any longer.

First 50 gallons of water.....RO/DI running now making more....still playing with rock:

Wohoo!!!!

A little over 75 gallons and the water is up to just under the sawteeth of the overflow.

I was surprised that the 1/2 inch foam under the tank only compressed a little over an 1/8 inch....and that's 645 pounds in water weight alone.

I was surprised that the 1/2 inch foam under the tank only compressed a little over an 1/8 inch....and that's 645 pounds in water weight alone.

- Joined

- Feb 21, 2017

- Messages

- 497

- Reaction score

- 248

A little over 75 gallons and the water is up to just under the sawteeth of the overflow.

I was surprised that the 1/2 inch foam under the tank only compressed a little over an 1/8 inch....and that's 645 pounds in water weight alone.

Paul are you going to use something to help speed up the cycle process?

Juan, thanks for the comment. I don't believe the cycle will be the problem. I'm a big believer in curing rock. I think uncured rock is the cause of many of the problems new tanks see with algae, diatoms, plague of locusts, etc., after setting up a tank with dry rock and thinking they only need a cycle. The dead stuff in dry rock needs time to completely decay and leach out of the rock. If you don't do this, the decay adds nutrients that feed wild growth of algae and cyano. My cure will take the time for the cycle to complete concurrent to the cure. I'm thinking a month to a month and a half. It's now time to hurry up a wait. Now I did jump start this with a bleach soak and in addition, this rock sat outside in all weather for years. The one good thing is that, although it's only been a couple hours, I don't have that nasty smell I've smelt when starting with "dirty" dry rock.

- Joined

- Feb 21, 2017

- Messages

- 497

- Reaction score

- 248

Juan, thanks for the comment. I don't believe the cycle will be the problem. I'm a big believer in curing rock. I think uncured rock is the cause of many of the problems new tanks see with algae, diatoms, plague of locusts, etc., after setting up a tank with dry rock and thinking they only need a cycle. The dead stuff in dry rock needs time to completely decay and leach out of the rock. If you don't do this, the decay adds nutrients that feed wild growth of algae and cyano. My cure will take the time for the cycle to complete concurrent to the cure. I'm thinking a month to a month and a half. It's now time to hurry up a wait. Now I did jump start this with a bleach soak and in addition, this rock sat outside in all weather for years. The one good thing is that, although it's only been a couple hours, I don't have that nasty smell I've smelt when starting with "dirty" dry rock.

Agree 100%

Good Bye Old Tank

great progress!

finally coming together.

I also think that starting with dry rock and not curing it/ letting it go thru its ugly phases is the cause of many problems.

finally coming together.

I also think that starting with dry rock and not curing it/ letting it go thru its ugly phases is the cause of many problems.

Definitely like this aquascape better than the original “concrete dump” with similar heights.

Going Hinge-less On Stand Doors

When I first built this stand, I included two paneled doors on the front with conventional 3/8 offset cabinet hinges. Over the years, I had to replace these because of rust. You can see the doors in this pic when the stand was just built:

When I finally ended up building the equipment cabinet, I wanted to eliminate hinges, and went with dowel pins on the bottom of the doors, with neo-magnets holding the top portion of the doors in the equipment cabinet. These worked great.

So with these double doors, to go hinge-less, the first thing I did was to attach the two doors together with two strips of 1/2 inch wood....glued and screwed.

You can see them in the picture above, the next thing was to put two wood biscuits in the bottom trim of the door.

A matching and large slot was cut into the base of the stand. The bottom of the door will now sit in the slots in the stand, where the biscuits line up to these slots, holding the door flush to the stand.

The top of the door will be drilled with a Forstner bit to counter sink 3 x 12 mm neo magnets...in both upper corners of the of the door. These magnets will align with what I call magnetic Mickey Mouse ears to hold the door closed.

I still need to make these new Mickey Mouse ears....sometime tonight. And these are drilled with a Forstner bit as well and the magnets held in place by epoxy glue.

When I first built this stand, I included two paneled doors on the front with conventional 3/8 offset cabinet hinges. Over the years, I had to replace these because of rust. You can see the doors in this pic when the stand was just built:

When I finally ended up building the equipment cabinet, I wanted to eliminate hinges, and went with dowel pins on the bottom of the doors, with neo-magnets holding the top portion of the doors in the equipment cabinet. These worked great.

So with these double doors, to go hinge-less, the first thing I did was to attach the two doors together with two strips of 1/2 inch wood....glued and screwed.

You can see them in the picture above, the next thing was to put two wood biscuits in the bottom trim of the door.

A matching and large slot was cut into the base of the stand. The bottom of the door will now sit in the slots in the stand, where the biscuits line up to these slots, holding the door flush to the stand.

The top of the door will be drilled with a Forstner bit to counter sink 3 x 12 mm neo magnets...in both upper corners of the of the door. These magnets will align with what I call magnetic Mickey Mouse ears to hold the door closed.

I still need to make these new Mickey Mouse ears....sometime tonight. And these are drilled with a Forstner bit as well and the magnets held in place by epoxy glue.

DIY Magnetic Door Latches - Mickey Mouse Ears

With a new supply of 3 x 12 mm Neodymium (Neo) Magnets (ORDERED HERE), it's time to make some more magnetic Mickey Mouse Ear door closures for the revised, hinge-less front door. I like these 12 mm size because they fit very nicely in a 1/2 inch hole, drilled with a Forstner bit. I've used these on the equipment cabinet, with magnets embedded in the door, and the Mickey Mouse ears on the cabinet carcass.

I only need two (maybe three) ears for the front door. However, I've used these in other projects, and will be using them in future projects, and if I'm making a couple, I might as well make a bunch. It's the setup that takes the time, so making a one, or making a bunch won't add much time to the making of these. Plan is to make a dozen.

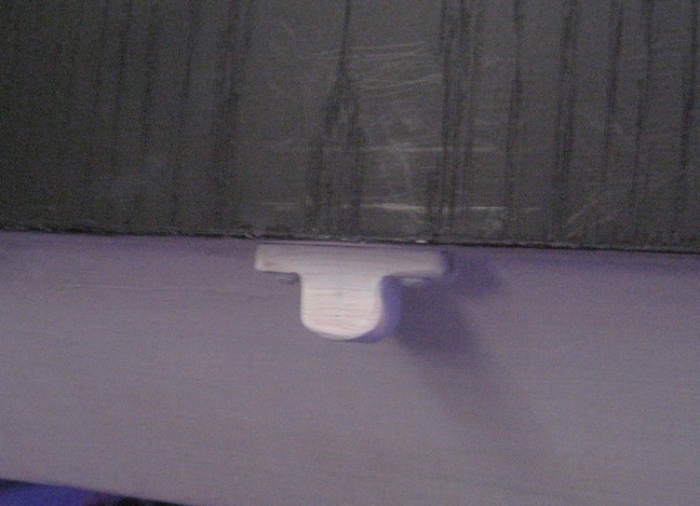

To start, I found a piece of scrap lumber that I ripped (cut) to 1/2 inch thick by 3/4 inches wide. Next was to put down lay-out lines, where each ear would be this 1/2 x 3/4 inches, by 1 1/2 inches long. The lay-out lines included an 1/8 inch between each ear for the width of the kerf (blade thickness) for when I cut them into individual ears. In addition, a 1/2 hole was drilled in each ear using a Forstner bit, just deep enough to bury the magnet. Two of the holes below have magnets sitting in them.

With the holes drilled, this piece was placed on edge and using a radial arm saw, the wood between each hole was nibbled out, leaving a little less than a 1/4 inch on the base. Now, with small drum sanders, and a coarse file, the ears were rounded out.

Magnets were placed in each hole, with a bit of epoxy in the bottom, and then filled in with more epoxy, allowed to cure over night, and filed flush.

Interestingly, I've been using JB Weld for years in projects and gluing frags in the tank. I noticed when I was filing that some of this filed epoxy was adhering to the ear....magnetically sticking. That is, it has ferrous metal within the epoxy. Even though the one tube is listed as "metal", I never though it actually contained metal. This now puts in question the use of JB Weld within the tank. I've never done ICP testing on my tank, but am now curious if metals were showing up in my tank.

So the magnets are glued in and filed flush...time to cut up the pieces into individual ears. The original thought was to use my radial arm saw...that's why I left an 1/8 inch space between each ear....and now have 12 individual ears. When I started to think about this, my concern was that after cutting, the magnet would "jump" onto the spinning blade and get shot across the room. Just didn't sound safe. So I went old school, and got out the old miter saw box and cut these ears up manually.

Now with 12 ears, time to drill holes for the screws. To simplify drilling of 24 holes, I made a simple jig from scrap lumber to hold the ears while being drilled.

Ears have now been spray painted white, and holes drilled in the door, with magnets epoxy glued into the holes...and curing overnight. Tomorrow, sand and paint the door...and install!

With a new supply of 3 x 12 mm Neodymium (Neo) Magnets (ORDERED HERE), it's time to make some more magnetic Mickey Mouse Ear door closures for the revised, hinge-less front door. I like these 12 mm size because they fit very nicely in a 1/2 inch hole, drilled with a Forstner bit. I've used these on the equipment cabinet, with magnets embedded in the door, and the Mickey Mouse ears on the cabinet carcass.

I only need two (maybe three) ears for the front door. However, I've used these in other projects, and will be using them in future projects, and if I'm making a couple, I might as well make a bunch. It's the setup that takes the time, so making a one, or making a bunch won't add much time to the making of these. Plan is to make a dozen.

To start, I found a piece of scrap lumber that I ripped (cut) to 1/2 inch thick by 3/4 inches wide. Next was to put down lay-out lines, where each ear would be this 1/2 x 3/4 inches, by 1 1/2 inches long. The lay-out lines included an 1/8 inch between each ear for the width of the kerf (blade thickness) for when I cut them into individual ears. In addition, a 1/2 hole was drilled in each ear using a Forstner bit, just deep enough to bury the magnet. Two of the holes below have magnets sitting in them.

With the holes drilled, this piece was placed on edge and using a radial arm saw, the wood between each hole was nibbled out, leaving a little less than a 1/4 inch on the base. Now, with small drum sanders, and a coarse file, the ears were rounded out.

Magnets were placed in each hole, with a bit of epoxy in the bottom, and then filled in with more epoxy, allowed to cure over night, and filed flush.

Interestingly, I've been using JB Weld for years in projects and gluing frags in the tank. I noticed when I was filing that some of this filed epoxy was adhering to the ear....magnetically sticking. That is, it has ferrous metal within the epoxy. Even though the one tube is listed as "metal", I never though it actually contained metal. This now puts in question the use of JB Weld within the tank. I've never done ICP testing on my tank, but am now curious if metals were showing up in my tank.

So the magnets are glued in and filed flush...time to cut up the pieces into individual ears. The original thought was to use my radial arm saw...that's why I left an 1/8 inch space between each ear....and now have 12 individual ears. When I started to think about this, my concern was that after cutting, the magnet would "jump" onto the spinning blade and get shot across the room. Just didn't sound safe. So I went old school, and got out the old miter saw box and cut these ears up manually.

Now with 12 ears, time to drill holes for the screws. To simplify drilling of 24 holes, I made a simple jig from scrap lumber to hold the ears while being drilled.

Ears have now been spray painted white, and holes drilled in the door, with magnets epoxy glued into the holes...and curing overnight. Tomorrow, sand and paint the door...and install!

Final Coat of Paint

I'm giving the doors and ears a second coat of paint, and a friend stops in and looks at the ears and states, "They aren't Mickey Mouse ears, they are miniature tombstones."

And here are the doors....or now it's just one, so door. Looks a little streaky because I just gave the panel portions another shot of paint. When it dries, it will be just fine.

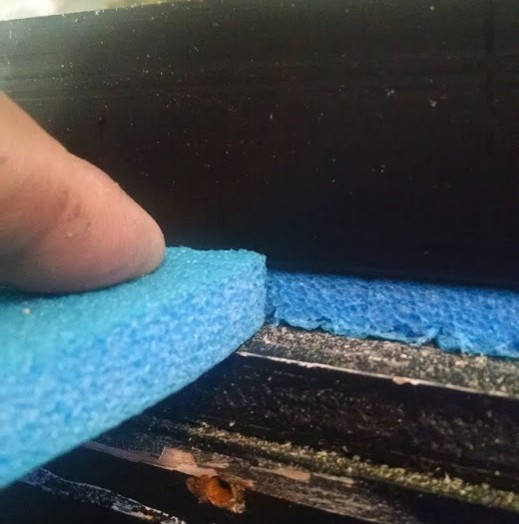

Next on the agenda, trim work around the base of the tank. The 1/2 foam I used only compressed about an eighth of an inch. Here's a picture of a piece of un-compressed foam in front of the tank, sitting on the compressed foam.

The issue is that when the trim board is put in place, about an eighth to 3/16 of the plastic base trim on the tank is exposed. Not sure if I am going to make new trim pieces or work up some other solution.

I'm giving the doors and ears a second coat of paint, and a friend stops in and looks at the ears and states, "They aren't Mickey Mouse ears, they are miniature tombstones."

And here are the doors....or now it's just one, so door. Looks a little streaky because I just gave the panel portions another shot of paint. When it dries, it will be just fine.

Next on the agenda, trim work around the base of the tank. The 1/2 foam I used only compressed about an eighth of an inch. Here's a picture of a piece of un-compressed foam in front of the tank, sitting on the compressed foam.

The issue is that when the trim board is put in place, about an eighth to 3/16 of the plastic base trim on the tank is exposed. Not sure if I am going to make new trim pieces or work up some other solution.

Similar threads

- Replies

- 2

- Views

- 317

- Replies

- 7

- Views

- 418

- Replies

- 3

- Views

- 162