I wouldn't do it for all the reasons already mentioned here...

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RO plumbed straight to sump? Good or bad idea?

- Thread starter smokin'reefer

- Start date

- Tagged users None

- Joined

- Dec 14, 2018

- Messages

- 19

- Reaction score

- 11

I'm planning on doing something close; my sump has an ATO res, and I plan on plumbing that. Will have a float valve in res. Back at the RO/DI unit (outside), there will be a solenoid that can detect that the float has closed, that will cut off the freshwater feed to the RO/DI unit.

It won't be left running all the time - I'm only really doing it as I have enough should drama that carrying containers of water around is becoming a bit of a problem. I will have a valve on the RO/DI inlet as well to shut it down when not needed. My res will fill within most of a day, so it's something that will only need to be turned on once a week, but should have enough fail safe built in that it will at least cut the water once full so I don't need to keep checking, and I can reasonably turn it off later without too much risk.

I figure there are some pros and cons:

Pros:

- No more carrying water.

- No more having to screw around filling containers

- Close to automated

- Should cut off when res is "full" (which will have a reasonable margin given my res holds more than enough water to last over a week, so "full" will not be full).

- Should cut off inlet to RO/DI, so will save water/filters

Cons:

- Still have to turn on/off RO/DI inlet and remember to check that res is full (easy enough)

- Still have to have a "day" where I do it (but at least it's just turn on/turn off).

- Always a flood risk (but at least can be minimised); but going to res first reduces the direct system impact, and having a process that doesn't involve it being always on reduces the potential for flood.

It won't be left running all the time - I'm only really doing it as I have enough should drama that carrying containers of water around is becoming a bit of a problem. I will have a valve on the RO/DI inlet as well to shut it down when not needed. My res will fill within most of a day, so it's something that will only need to be turned on once a week, but should have enough fail safe built in that it will at least cut the water once full so I don't need to keep checking, and I can reasonably turn it off later without too much risk.

I figure there are some pros and cons:

Pros:

- No more carrying water.

- No more having to screw around filling containers

- Close to automated

- Should cut off when res is "full" (which will have a reasonable margin given my res holds more than enough water to last over a week, so "full" will not be full).

- Should cut off inlet to RO/DI, so will save water/filters

Cons:

- Still have to turn on/off RO/DI inlet and remember to check that res is full (easy enough)

- Still have to have a "day" where I do it (but at least it's just turn on/turn off).

- Always a flood risk (but at least can be minimised); but going to res first reduces the direct system impact, and having a process that doesn't involve it being always on reduces the potential for flood.

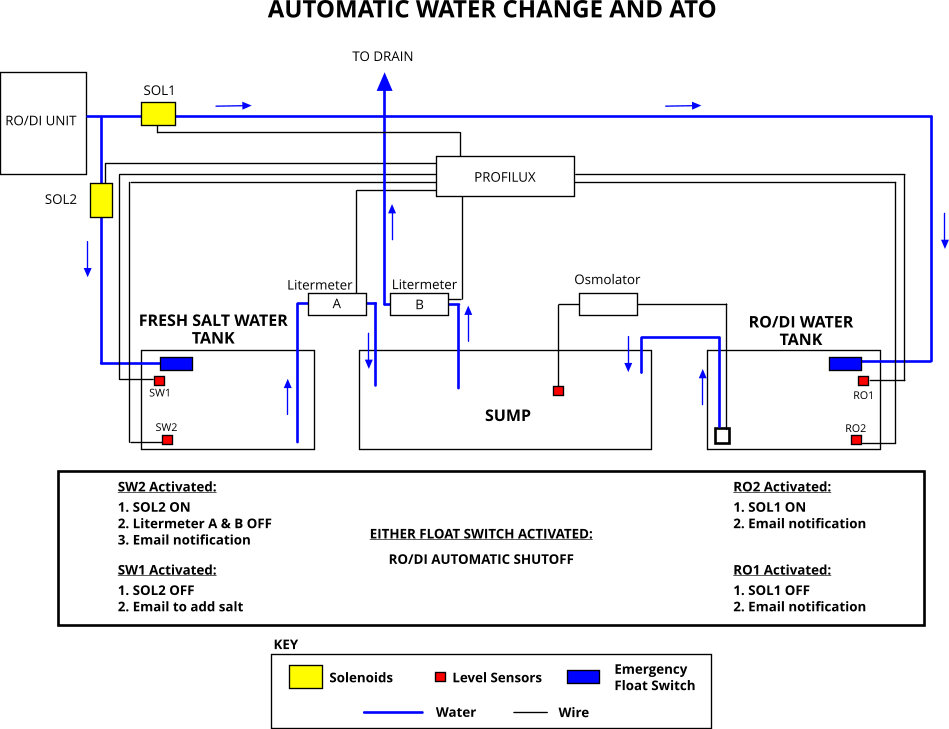

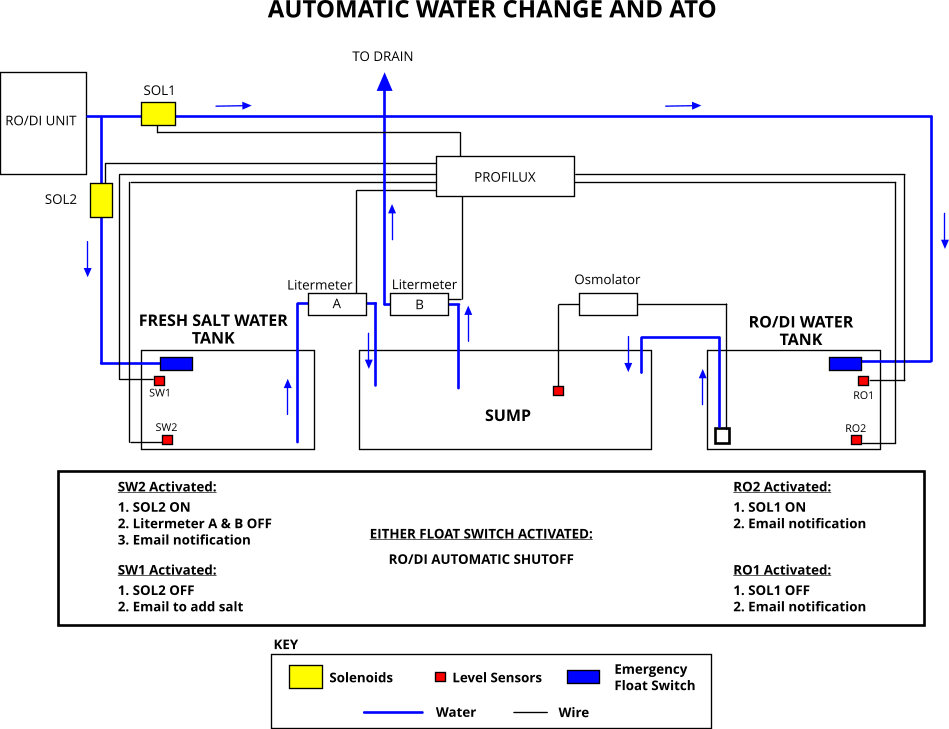

If you have a controller, you can also have the solenoid power on when the TO container is near empty. This is how I've set up mine:

I'm envisioning something similar... One question I have, do you use a booster pump on your rodi unit? If so how did you wire the solenoids to independently shut power on and off to the booster pump? You don't want that thing running and dead heading all day long and you could have one, both or nether solenoid open at a given time. I can't use an osmolater from my large storage bin because it's too far away so I'm using a smaller ro container to feed a kalk reactor.If you have a controller, you can also have the solenoid power on when the TO container is near empty. This is how I've set up mine:

I'm envisioning something similar... One question I have, do you use a booster pump on your rodi unit? If so how did you wire the solenoids to independently shut power on and off to the booster pump? You don't want that thing running and dead heading all day long and you could have one, both or nether solenoid open at a given time. I can't use an osmolater from my large storage bin because it's too far away so I'm using a smaller ro container to feed a kalk reactor.

Yes, I use a booster pump. You just install an auto shutoff valve that shuts off the booster pump as soon as the pressure builds up when the solenoids power off.

Something like this.

Usually you can order the booster pump with the auto shutoff valve...

thanks for the reply! So i already have one of those installed where my RO line is going into my large RO storage container. How do you wire a second one in on a line that's T'd off the first one, or am I not thinking about it correctly? I suppose running a T after it, it would still operate the same way right? Once the other line opened up the solenoid would open back up right? Just thinking this thru... thanks!Yes, I use a booster pump. You just install an auto shutoff valve that shuts off the booster pump as soon as the pressure builds up when the solenoids power off.

Something like this.

Usually you can order the booster pump with the auto shutoff valve...

thanks for the reply! So i already have one of those installed where my RO line is going into my large RO storage container. How do you wire a second one in on a line that's T'd off the first one, or am I not thinking about it correctly? I suppose running a T after it, it would still operate the same way right? Once the other line opened up the solenoid would open back up right? Just thinking this thru... thanks!

I installed the autoshutoff valve at the RO/DI unit itself. It doesn't care which solenoid is on or off; as soon as the pressure in the line at the RO/DI unit rises, it shuts off the booster pump. In my setup this only happens if both solenoids are off (flow is off). If one of the solenoids is on (flow on), there is no back pressure and therefore the booster pump keeps running.

Perfect, it was late last night when i was wrangling all this out in my head and I had a few pistons that weren't firing obviously. Appreciate you getting my head on straight lol.I installed the autoshutoff valve at the RO/DI unit itself. It doesn't care which solenoid is on or off; as soon as the pressure in the line at the RO/DI unit rises, it shuts off the booster pump. In my setup this only happens if both solenoids are off (flow is off). If one of the solenoids is on (flow on), there is no back pressure and therefore the booster pump keeps running.

I think RODI direct to sump is the best way to do ATO, IF done properly.

For me that means a RODI that is automatically turned on and off once or twice a day, filling a pressure tank. TDS creep is not a problem with a short flush at the beginning of the cycle and a pressure switch set so that the pressure tank never sees to high a psi. For someone who wants a more manual solution that could be a pressure tank of you're choice in size, and manually filling it as needed, just as you would a ato container. This pressure tank limits the amount of water that can flow into the tank to whatever it can hold.

Then the RODI needs to be connected to the sump properly. I have a needle valve in line OUTSIDE the sump, set to slightly above evaporation rate. This means that the entire pressure tank cant just dump into the sump if anything (including tubing) were to fail.

Then I have a decent quality float valve- this valve is constantly getting cleaned by the RODI water, so is should not fail.

So you end up with the same number of safeties as a ATO, and you don't have the human error of forgetting to fill it (assuming you automate it). And all the parts are far more reliable than the parts that make up a ato- pumps and float switches or optical switches.

My most recent tank ran like that for 7 years, with not one single problem. And it cost a lot less. Most atos I have had fail after a few years, or something goes wrong with them every once and a while. So while it is not right for every situation or person, I would highly recommend it as a option.

For me that means a RODI that is automatically turned on and off once or twice a day, filling a pressure tank. TDS creep is not a problem with a short flush at the beginning of the cycle and a pressure switch set so that the pressure tank never sees to high a psi. For someone who wants a more manual solution that could be a pressure tank of you're choice in size, and manually filling it as needed, just as you would a ato container. This pressure tank limits the amount of water that can flow into the tank to whatever it can hold.

Then the RODI needs to be connected to the sump properly. I have a needle valve in line OUTSIDE the sump, set to slightly above evaporation rate. This means that the entire pressure tank cant just dump into the sump if anything (including tubing) were to fail.

Then I have a decent quality float valve- this valve is constantly getting cleaned by the RODI water, so is should not fail.

So you end up with the same number of safeties as a ATO, and you don't have the human error of forgetting to fill it (assuming you automate it). And all the parts are far more reliable than the parts that make up a ato- pumps and float switches or optical switches.

My most recent tank ran like that for 7 years, with not one single problem. And it cost a lot less. Most atos I have had fail after a few years, or something goes wrong with them every once and a while. So while it is not right for every situation or person, I would highly recommend it as a option.

Bad idea. It's not accident proof. I use a 10g pale with float. Ro/di runs 1 hour a day to 10g pale. Aqualifer hooked up to ato controls sump level and pulls from 10g pale Accident proof

Mine has been running fine from ro.

I ran extra lines and aquabus cables to set up the ATK with my Apex. But I just can't justify switching. People say you need all these safeguards, but there is so much complexity that it seems to me it would add more failure points than it would solve.

As to using an exorbitant amount of DI resin, not in my opinion. I change one DI cartridge about every other month. And that includes water change water with the top off.

KISS system rules the day.

I ran extra lines and aquabus cables to set up the ATK with my Apex. But I just can't justify switching. People say you need all these safeguards, but there is so much complexity that it seems to me it would add more failure points than it would solve.

As to using an exorbitant amount of DI resin, not in my opinion. I change one DI cartridge about every other month. And that includes water change water with the top off.

KISS system rules the day.

Nope, its not complex or difficult to set up. I had a electronic float fail once, and without this proper set up, the tank could have been flooded with fresh water. Its not hard to run a 10g garbage pale with a mechanical float and have your ro/di come on for one hour a day to keep the pale full. So for me the worse possible failure on circut #1 is water on a concrete floor that will drain outside. Electronics fail so its safe guarding by having 2 separate circuts, the odds of 2 failure at the same time almost impossible. The second is the sumps ATO dual floats with an aqualifter that draws out of the 10G pale. Again if electronic floats fail, I only have 10G of fresh water in a 300G system. So impossible for any failure to effect tank. I have thousands in coral and cant take a loss.there is so much complexity

Yes sir! and what I propose is as simple as it gets while retaining tank safety.KISS system rules the day.

Been running RO direct for 16 years. Multiple fail safes with timers, floats and solenoids with no issues.

Funny thing is we have toilets in our homes that operate on a single float only, no electronics or timers to hold back a full pressure water line. What are we thinking

Funny thing is we have toilets in our homes that operate on a single float only, no electronics or timers to hold back a full pressure water line. What are we thinking

Similar threads

- Replies

- 3

- Views

- 301

- Replies

- 2

- Views

- 84

- Replies

- 2

- Views

- 143

- Replies

- 10

- Views

- 351