So, because I read somewhere that you shouldn't drill holes too close to the edges of the glass, my returns are a bit deep, putting my loc line about 1.5" below the water line at the bulkhead. Unless I point the returns up towards the surface, there's a ton of drainage hitting my sump whenever the return pump shuts off. Where can I put a siphon break in something so deep under the water line? Unless I pull the loc line upwards and then point the nozzle parallel to the water line? That'll look a bit goofy, but if the nozzle is closer to the water line, I'm less likely to overflow my sump. For reference, it's a 120g with a 40b, Modular Marine overflow. The primary siphon is just a flat strainer in the bulkhead, secondary is a durso standpipe that has a hole drilled in the top for a piece of airline tubing that curls back into the interior box just above the waterline. The emergency drain is just an open pipe that sits higher than the others. Thoughts on the siphon break? Make the loc lines look weird by snaking them upwards and then parallel with the waterline, drill holes in the undersides...? Thanks!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Siphon break in loc lines?

- Thread starter SallyWho

- Start date

- Tagged users None

So, because I read somewhere that you shouldn't drill holes too close to the edges of the glass, my returns are a bit deep, putting my loc line about 1.5" below the water line at the bulkhead. Unless I point the returns up towards the surface, there's a ton of drainage hitting my sump whenever the return pump shuts off. Where can I put a siphon break in something so deep under the water line? Unless I pull the loc line upwards and then point the nozzle parallel to the water line? That'll look a bit goofy, but if the nozzle is closer to the water line, I'm less likely to overflow my sump. For reference, it's a 120g with a 40b, Modular Marine overflow. The primary siphon is just a flat strainer in the bulkhead, secondary is a durso standpipe that has a hole drilled in the top for a piece of airline tubing that curls back into the interior box just above the waterline. The emergency drain is just an open pipe that sits higher than the others. Thoughts on the siphon break? Make the loc lines look weird by snaking them upwards and then parallel with the waterline, drill holes in the undersides...? Thanks!

Set the loc line up such that coming out of the bulkhead it goes up toward the surface and then back down and point the nozzle where you want it. Then drill a hole on the under side of the lock line at the point closest to the surface. Do not drill a hole pointing towards the water line otherwise you’ll probably spray water everywhere. The hole on the under side will break the siphon at a higher point and the flow out of the hole will be downward and shouldn’t be noticeable. With it being on the underside, it will also help prevent coralline from growing over it. You’ll just have to make sure this hole is clogged by anything else.

A lot of people just snake the Loc line up to surface level. I mean you could install something that would siphon without you needed to do anything with your loc line but it would be some work.

Great, guys! Thanks! I'm currently leak testing my third try at plumbing (I suck so hard at plumbing and it's absolutely infuriating), so when it's done, I'll pull the loc lines to drill a couple of small holes on the undersides. I'm glad I kept some of the extra links- I'd broken it into shorter sections so they didn't intrude on the tank so much, but angling them appropriately will require a bit more length. I'll just have to get used to longer return lines in the tank!

Mark Levenson has a good way of breaking a siphon. I used it on my tank and it works really well. Of course it will have to be adapted to your specific tank. With a little creativity it should not be too hard. https://www.reef2rainforest.com/201...nstrates-the-anti-siphon-reverse-check-valve/

Another option is to use a pair of black PVC 90 degree elbows to get the loc line up to the surface. It'll cost you a bit of flow but it's more aesthetically appealing (to me at least).

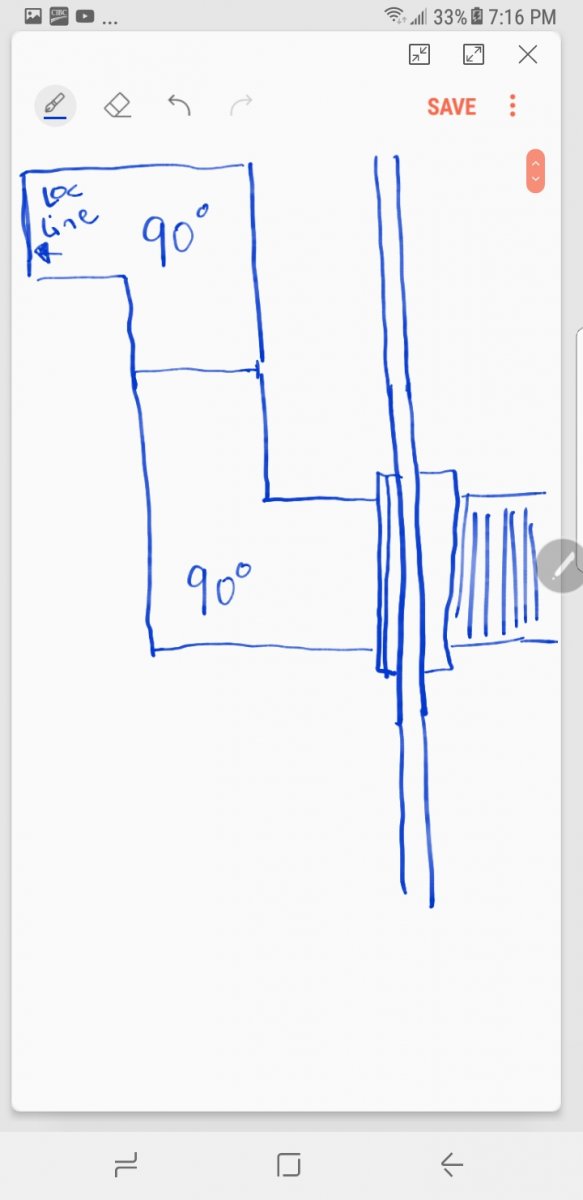

I'm having troubling picturing what you mean. Can you sketch it out for me?Another option is to use a pair of black PVC 90 degree elbows to get the loc line up to the surface. It'll cost you a bit of flow but it's more aesthetically appealing (to me at least).

Oohhhhhhhhh, okay. That does make sense. I'll see if I can find any appropriately sized elbows and give that a shot. It'd be super easy to drill a siphon break hole in that set up.I do believe this is what @ca1ore means...

- Joined

- Jan 11, 2016

- Messages

- 1,668

- Reaction score

- 1,221

I have my loc lines go up then bend down so the nozzles are just beneath the water line. This way I only drain about half an inch of water at most and my sump can handle that no problem. I also have a check valve for redundancy.

Sadly, I didn't have room for a check valve in my return plumbing before the line split to go to each return. Otherwise, I'd have given it a shot! I thought about taking everything apart and putting a check valve on each return line near the bulkhead, but I'm having enough trouble with leaks in my plumbing (seriously, it just failed a third leak test after cutting, replacing, and regluing the problem areas after each failure) that purposefully cutting apart the parts that are okay in order to install one or two sounded like such a headache that I ditched the idea!I have my loc lines go up then bend down so the nozzles are just beneath the water line. This way I only drain about half an inch of water at most and my sump can handle that no problem. I also have a check valve for redundancy.

Similar threads

- Replies

- 17

- Views

- 279

- Replies

- 15

- Views

- 456