- Joined

- Apr 17, 2018

- Messages

- 123

- Reaction score

- 102

Hello, wanted to share my findings on the COR 20 for my particular setup incase it helps anyone else. Also, I’m looking for some advices on what would be the recommended turn over rate for my setup.

The original goal was a 10x turn over rate, however was disappointed after multiple results show I was quite under my goal even at max.

Incase your considering this pump, here is my setup to compare to see if this pump would be powerful enough for you.

80 lbs of Fiji pink sand

90 lbs of pukano rock

Plumbing of 1.25

Tank size 150 60x24x24

Measurement from top of sand to water line is 59x22.5x22

Display is around 117 gallon after water displacement.

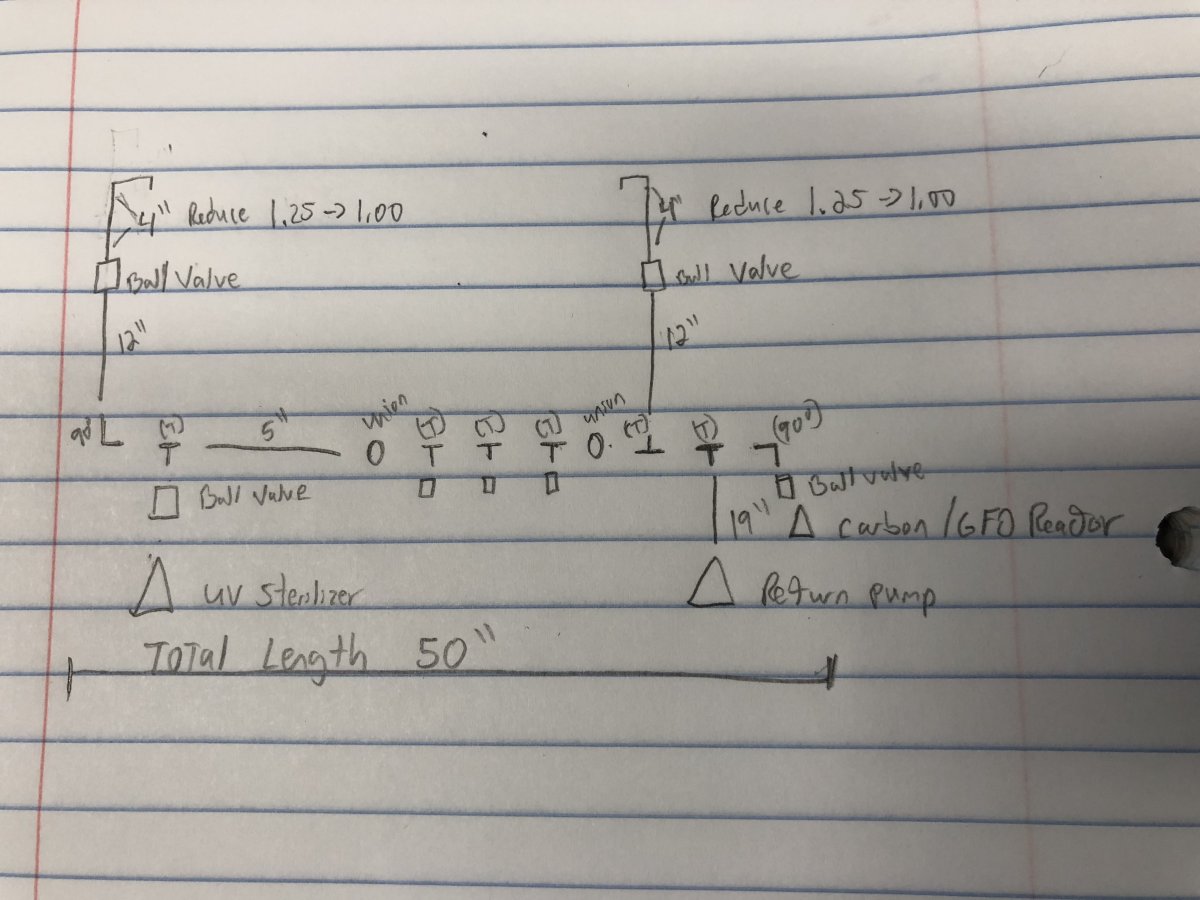

Here is an idea of my current plumbing:

I ran a series of 3 test for each side of my return for each of the speeds. Neptune cor has 8 dots that individually get brighter until it’s max brightness and then moves on to the next dot, etc till it reaches max at the 8 dot. Note the UV ball valve was close.

This were ran at the max speed (brightness) of the following:

At max brightness 5: 685 gallon per hour

At max brightness 6: 800 gallon per hour

At max brightness 7: 913 gallon per hour

At max brightness 8: 950 gallon per hour

Hopes this helps give you an idea of what to expect if your looking a pump as such for your setup.

If anyone could lend some advise, I’m still cycling the tank. Plan is future mix reef. Was going to do Triton but do to lack of the 10x flow thinking I’m going to go with kalk and Red Sea trace elements to start, what would you recommend I should use for the flow rate for this setup? Not sure of running it at max 8 since I’m concern of the pump wearing down faster. Thanks!

The original goal was a 10x turn over rate, however was disappointed after multiple results show I was quite under my goal even at max.

Incase your considering this pump, here is my setup to compare to see if this pump would be powerful enough for you.

80 lbs of Fiji pink sand

90 lbs of pukano rock

Plumbing of 1.25

Tank size 150 60x24x24

Measurement from top of sand to water line is 59x22.5x22

Display is around 117 gallon after water displacement.

Here is an idea of my current plumbing:

I ran a series of 3 test for each side of my return for each of the speeds. Neptune cor has 8 dots that individually get brighter until it’s max brightness and then moves on to the next dot, etc till it reaches max at the 8 dot. Note the UV ball valve was close.

This were ran at the max speed (brightness) of the following:

At max brightness 5: 685 gallon per hour

At max brightness 6: 800 gallon per hour

At max brightness 7: 913 gallon per hour

At max brightness 8: 950 gallon per hour

Hopes this helps give you an idea of what to expect if your looking a pump as such for your setup.

If anyone could lend some advise, I’m still cycling the tank. Plan is future mix reef. Was going to do Triton but do to lack of the 10x flow thinking I’m going to go with kalk and Red Sea trace elements to start, what would you recommend I should use for the flow rate for this setup? Not sure of running it at max 8 since I’m concern of the pump wearing down faster. Thanks!