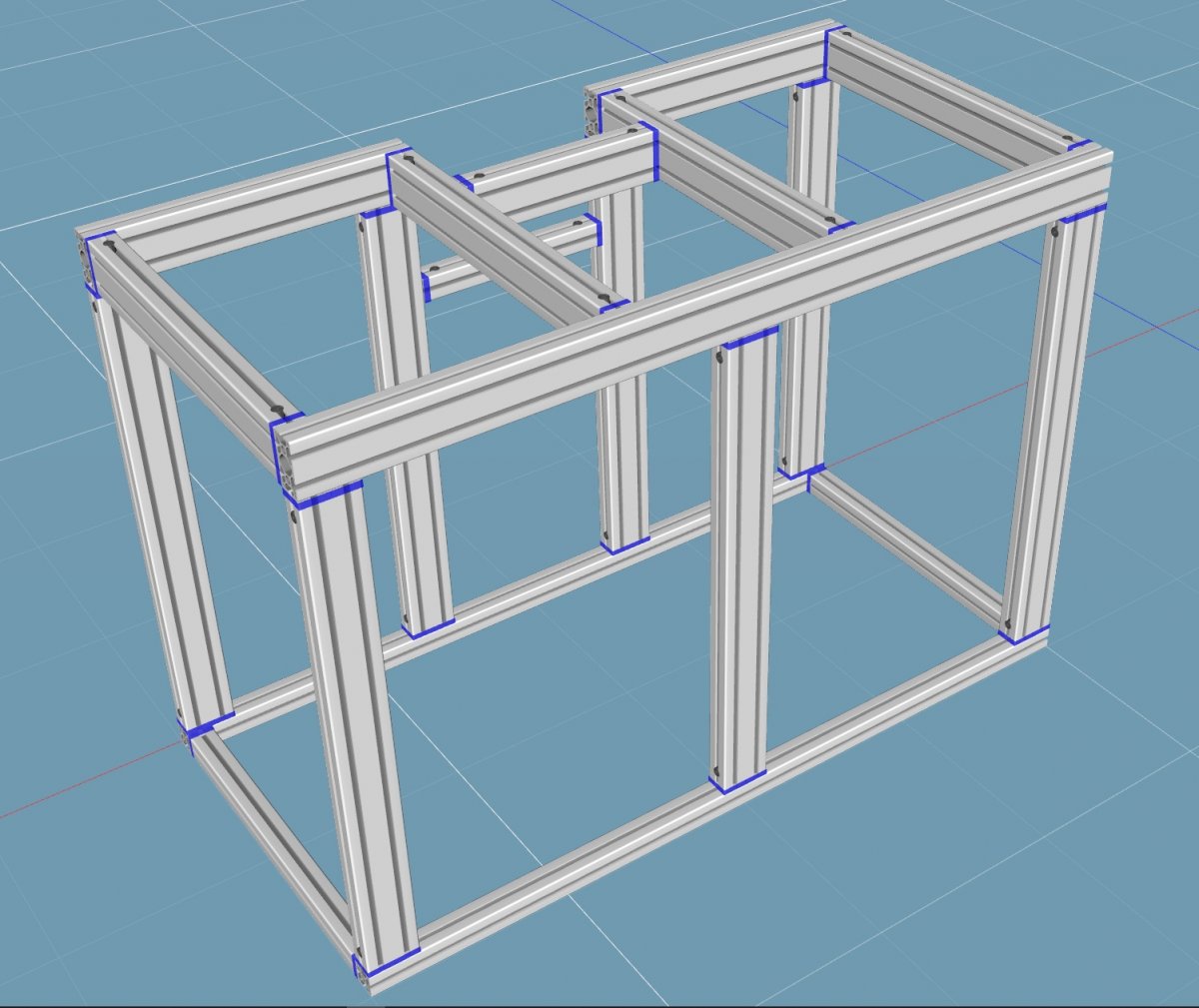

I currently have a 90g 36x24x24 rimless tank with center overflow, and a 26x13x15 acrylic sump. I wanted a stand that could hold it, but also be able to hold a 48x24 footprint tank in the future if I decide to upgrade. Current tank would sit centered on top of the stand. Here's what I've come up with so far.

Unfortunately the program I'm using is somewhat... limited... in its selection of fasteners and panels so I couldn't put panels or doors on it, but basically what I'm going for is a 48:x24Wx36H stand (height is including leveling feet or leveling casters and minimum 3/4 inch thick top which is required for my tank's warranty), doors, side and back panels, bottom shelf and top shelf.

The notch out of the rear of the top frame is for access to the bulkheads and plumbing. The tank mfg has plywood and mdf stands that they do this with, they have a notch cut out of the top and back going in roughly the size of the overflow on the top and down about 6-8 inches on the back that's all open. I liked that aspect of their stands (but didn't like plywood and mdf for an aquarium stand) so I tried to copy it here. The cross brace on the rear is just to give something for the back panel to attach to in the center where it's notched down for plumbing access, everything above that cross brace (and between the uprights) on the rear and behind the cross brace in the center of the top will be uncovered by panels.

Thoughts? Is it not enough, is is stupid levels of overkill, any glaring issues I'm missing?

Unfortunately the program I'm using is somewhat... limited... in its selection of fasteners and panels so I couldn't put panels or doors on it, but basically what I'm going for is a 48:x24Wx36H stand (height is including leveling feet or leveling casters and minimum 3/4 inch thick top which is required for my tank's warranty), doors, side and back panels, bottom shelf and top shelf.

The notch out of the rear of the top frame is for access to the bulkheads and plumbing. The tank mfg has plywood and mdf stands that they do this with, they have a notch cut out of the top and back going in roughly the size of the overflow on the top and down about 6-8 inches on the back that's all open. I liked that aspect of their stands (but didn't like plywood and mdf for an aquarium stand) so I tried to copy it here. The cross brace on the rear is just to give something for the back panel to attach to in the center where it's notched down for plumbing access, everything above that cross brace (and between the uprights) on the rear and behind the cross brace in the center of the top will be uncovered by panels.

Thoughts? Is it not enough, is is stupid levels of overkill, any glaring issues I'm missing?