You need a 1/8” port connector, SS-201-PC

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building an Alanle style dual stage CO2 regulator

- Thread starter Water Dog

- Start date

- Tagged users None

Awesome! Thanks!You need a 1/8” port connector, SS-201-PC

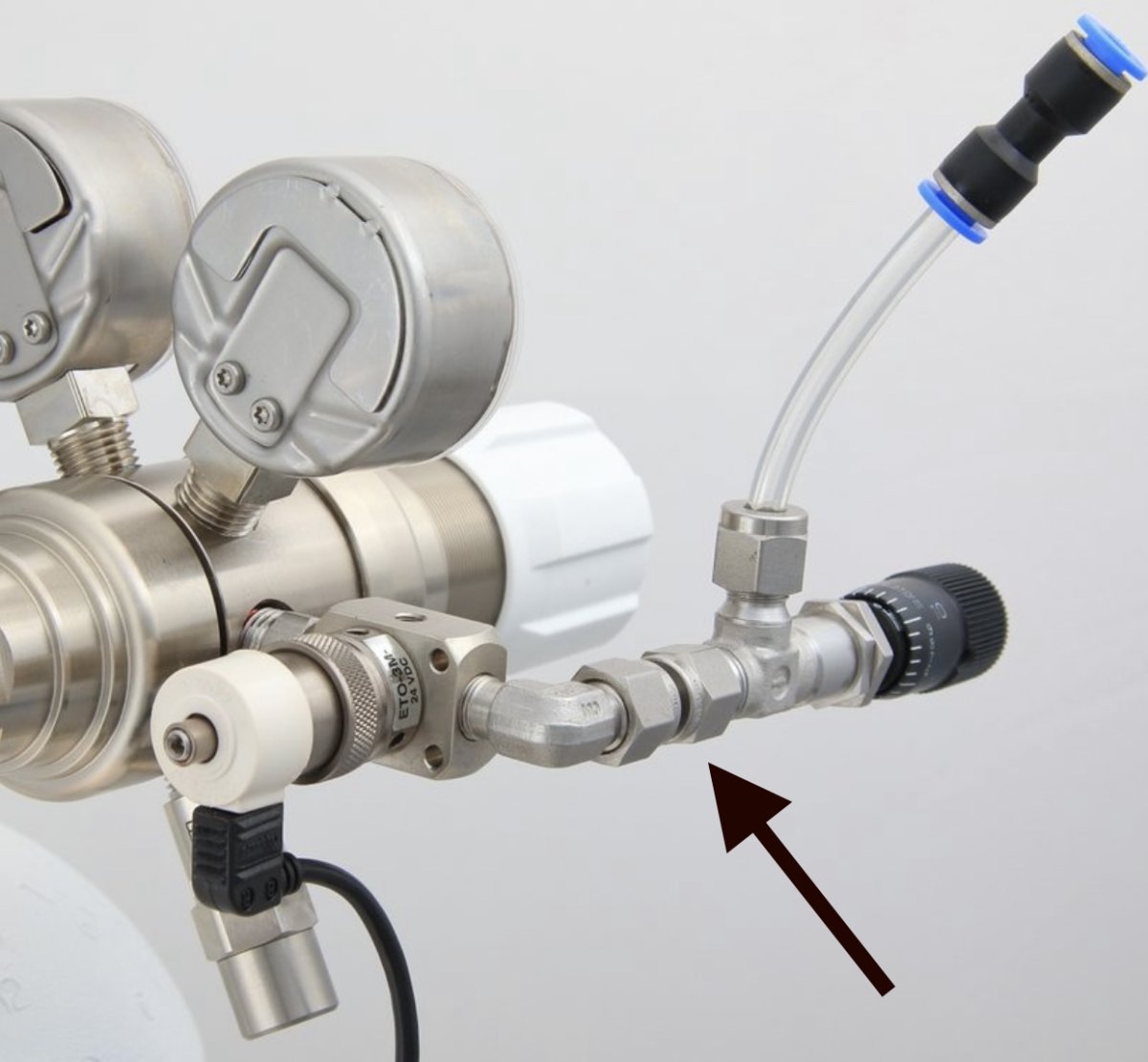

This is what you need. Ebay #175521967209Hey all, I’m in the process of gathering all my fittings for my build and am basing mine off of the regulator in the image below. Only thing is I’m not sure which fitting to use to connect the metering valve to the elbow? In swagelok part #s it looks like I need a fitting of some sort to connect SS-200-2-2 (the elbow) to SS-SS2-A (the metering valve). Could someone point me in the right direction?

I picked up this regulator from eBay, however I'm finding the CGA-320 threading doesn't want to screw into the body. Is it possible I picked up the wrong type of regulator? Or is there a different stem that would work? The stem that came with the regulator has a bit of a taper to the threads, and the connection point is obviously meant for a different style tank.

Attachments

I picked up this regulator from eBay, however I'm finding the CGA-320 threading doesn't want to screw into the body. Is it possible I picked up the wrong type of regulator? Or is there a different stem that would work? The stem that came with the regulator has a bit of a taper to the threads, and the connection point is obviously meant for a different style tank.

Sorry, I missed this... Unless my eyes are deceiving me, looking at your picture of the two tank fittings side by side, it looks like your CGA-320 CO2 fitting has reverse threads.

Make sure your CGA-320 fitting has a 1/4” NPT male fitting.

Nice!Just built this mini dual stage regulator. This thing is small but it’s a beast.

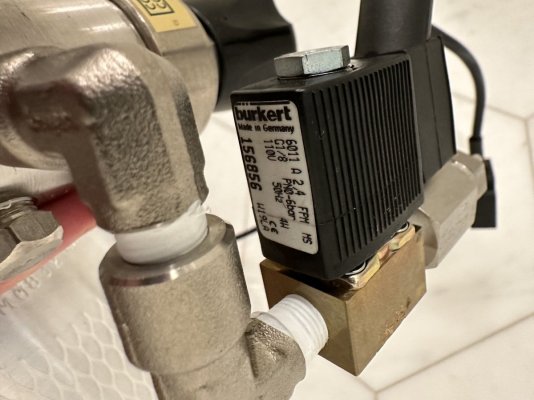

Working on building one myself, running into an issue with the burkert solenoid not holding pressure (but maybe it doesn’t need to?) Question is, should the burkert be able to hold 60 psi of pressure? Total noob question, just want to make sure I don’t have a bad solenoid before I finish assembling the rest. I’ve plugged the solenoid in and it opens with power, closes when unplugged. Thanks in advance!

Attachments

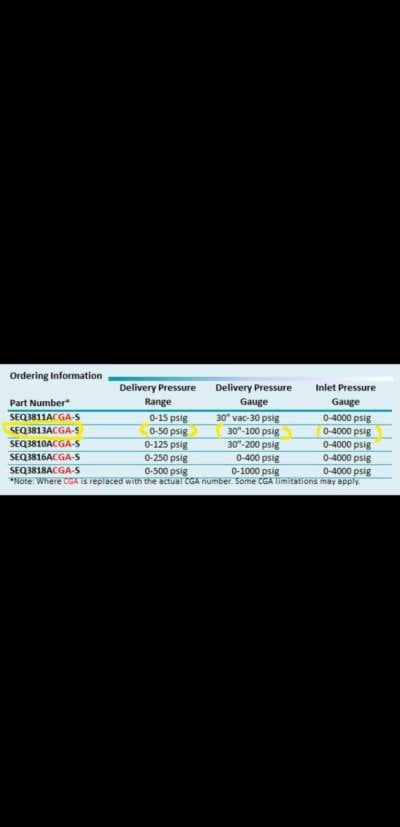

Hello I'm new here but have been lurking for quite a while. I'm currently set up with only heavily planted freshwater setups. I'm switching from C02art products and like due to QA issues. I've purchased a 3810a regulator adjustable to 100 psi my question is what would be needed to adapt this design to run a dual output setup for two side by side freshwater tanks. I know my working pressure will likely need to be 40-50 psi I'm not sure how this would work with a dual output manifold to the needle valves and mounted bubble counters?

- Joined

- Jan 3, 2018

- Messages

- 834

- Reaction score

- 699

You should just need two needle valves and two bubble counters with the necessary piping tees and other fittings to make a manifold. Assuming you can accept both tanks having the same CO2 on/off schedule you would only need one solenoid valve. Otherwise, you would want two of those as well.

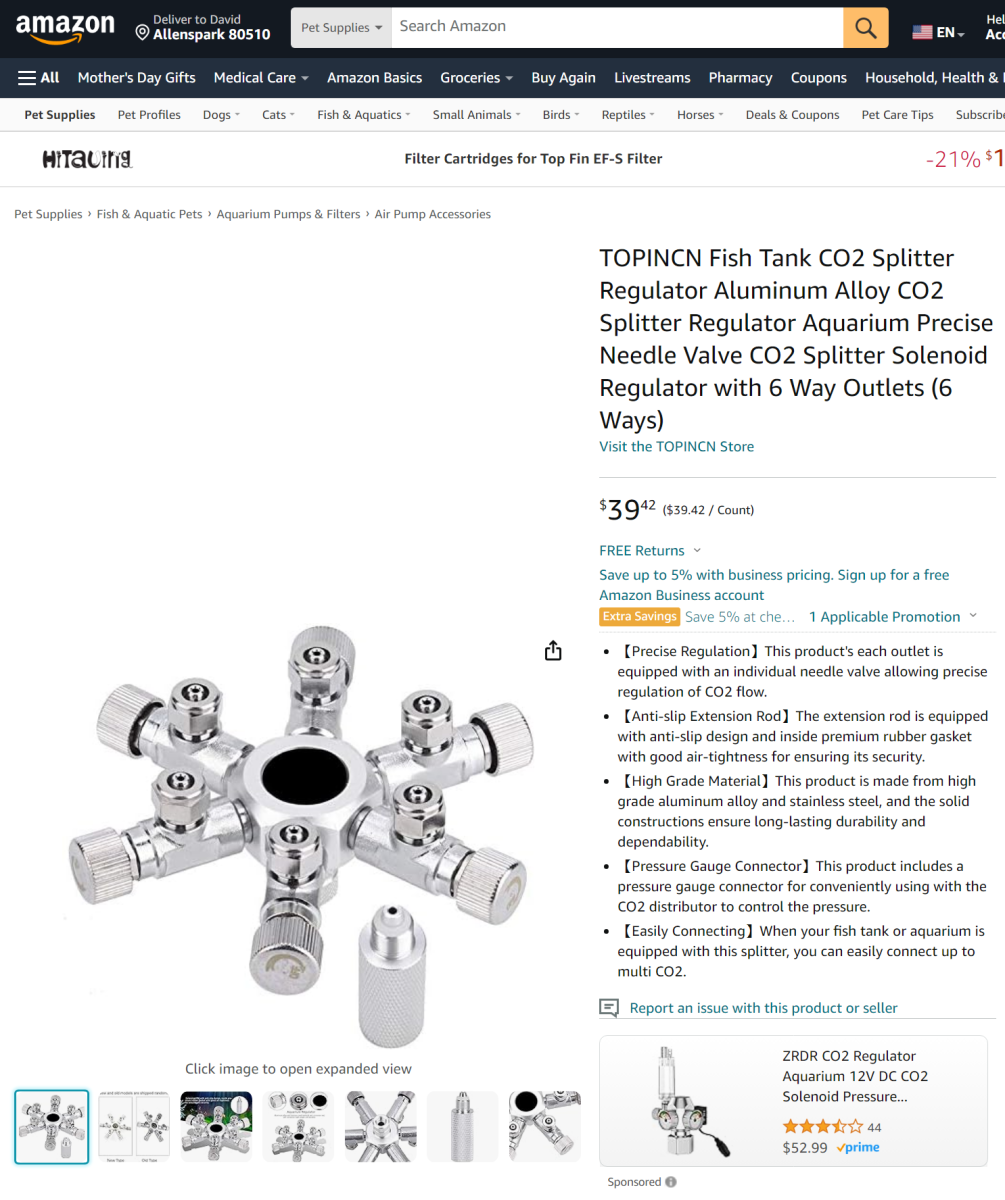

They make splitter valve manifolds with up to about 6 needle valves in a spider pattern. You can connect the tubing to the outlet. You can find them online. I use one to supply two of my freshwater tanks from a single regulator and solenoid and they work well but I keep my operating pressure closer to 15 psi. They might be difficult to control at 50 psi depending on how man bubbles you want. The needle valve is not as precise as a Swagelok needle valve, but they are a lot cheaper. That should be a very good regulator capable of turning down much lower than 50 psig if you need to. You do have to purchase separate bubble counters. I have used the Fluval units for this. They are easy because they can just be inserted into the tubing anywhere, although I built one into each of my DIY PVC Griggs reactors with a short vertical section of 1/2" clear PVC in the CO2 injection port that I like better because they do not have to be refilled with fluid. Obviously, this would not work with a diffuser and then I would probably just use the Fluval bubble counters but I much prefer a Griggs reactor over a diffuser as there is no maintenance on them. I have never used the metallic bubble counters that mount directly onto the piping.

The saltwater calcium reactors have a much lower bubble rate than a planted tank system, so you will see a lot of recommendations for very fine needle valves on this site that really are not necessary on a typical freshwater tank.

They make splitter valve manifolds with up to about 6 needle valves in a spider pattern. You can connect the tubing to the outlet. You can find them online. I use one to supply two of my freshwater tanks from a single regulator and solenoid and they work well but I keep my operating pressure closer to 15 psi. They might be difficult to control at 50 psi depending on how man bubbles you want. The needle valve is not as precise as a Swagelok needle valve, but they are a lot cheaper. That should be a very good regulator capable of turning down much lower than 50 psig if you need to. You do have to purchase separate bubble counters. I have used the Fluval units for this. They are easy because they can just be inserted into the tubing anywhere, although I built one into each of my DIY PVC Griggs reactors with a short vertical section of 1/2" clear PVC in the CO2 injection port that I like better because they do not have to be refilled with fluid. Obviously, this would not work with a diffuser and then I would probably just use the Fluval bubble counters but I much prefer a Griggs reactor over a diffuser as there is no maintenance on them. I have never used the metallic bubble counters that mount directly onto the piping.

The saltwater calcium reactors have a much lower bubble rate than a planted tank system, so you will see a lot of recommendations for very fine needle valves on this site that really are not necessary on a typical freshwater tank.

You should just need two needle valves and two bubble counters with the necessary piping tees and other fittings to make a manifold. Assuming you can accept both tanks having the same CO2 on/off schedule you would only need one solenoid valve. Otherwise, you would want two of those as well.

They make splitter valve manifolds with up to about 6 needle valves in a spider pattern. You can connect the tubing to the outlet. You can find them online. I use one to supply two of my freshwater tanks from a single regulator and solenoid and they work well but I keep my operating pressure closer to 15 psi. They might be difficult to control at 50 psi depending on how man bubbles you want. The needle valve is not as precise as a Swagelok needle valve, but they are a lot cheaper. That should be a very good regulator capable of turning down much lower than 50 psig if you need to. You do have to purchase separate bubble counters. I have used the Fluval units for this. They are easy because they can just be inserted into the tubing anywhere, although I built one into each of my DIY PVC Griggs reactors with a short vertical section of 1/2" clear PVC in the CO2 injection port that I like better because they do not have to be refilled with fluid. Obviously, this would not work with a diffuser and then I would probably just use the Fluval bubble counters but I much prefer a Griggs reactor over a diffuser as there is no maintenance on them. I have never used the metallic bubble counters that mount directly onto the piping.

The saltwater calcium reactors have a much lower bubble rate than a planted tank system, so you will see a lot of recommendations for very fine needle valves on this site that really ar

You should just need two needle valves and two bubble counters with the necessary piping tees and other fittings to make a manifold. Assuming you can accept both tanks having the same CO2 on/off schedule you would only need one solenoid valve. Otherwise, you would want two of those as well.

They make splitter valve manifolds with up to about 6 needle valves in a spider pattern. You can connect the tubing to the outlet. You can find them online. I use one to supply two of my freshwater tanks from a single regulator and solenoid and they work well but I keep my operating pressure closer to 15 psi. They might be difficult to control at 50 psi depending on how man bubbles you want. The needle valve is not as precise as a Swagelok needle valve, but they are a lot cheaper. That should be a very good regulator capable of turning down much lower than 50 psig if you need to. You do have to purchase separate bubble counters. I have used the Fluval units for this. They are easy because they can just be inserted into the tubing anywhere, although I built one into each of my DIY PVC Griggs reactors with a short vertical section of 1/2" clear PVC in the CO2 injection port that I like better because they do not have to be refilled with fluid. Obviously, this would not work with a diffuser and then I would probably just use the Fluval bubble counters but I much prefer a Griggs reactor over a diffuser as there is no maintenance on them. I have never used the metallic bubble counters that mount directly onto the piping.

The saltwater calcium reactors have a much lower bubble rate than a planted tank system, so you will see a lot of recommendations for very fine needle valves on this site that really are not necessary on a typical freshwatr tank.

Thanks my biggest issue with the retail models on the market is the quality and the control with the garbage valves they use on those systems the amount a person pays for an off the shelf "highend" product is just ridiculous. I'm just sick of dealing with crap labeled as top of the line. I want to set my bubble count and it not move while I'm sleeping and kill all of my livestock. I would really like something dependable every single time so I will spend the money for a great valve with quality adjustment. I'm hoping I can find a y section to build off of that if I go inline I will go with my tried and true ada beetle I set up on all of my display tanks. Not sure what part number or if anyone knew if that part even existed

So this is the unit I purchased as open box item on ebay for $400 I'm sure I overpaid but seemed like a good deal at the time and astheticly pleasing. This is what I'll be using for my 2 tank build for my display aquascapes. I've been looking for a good set of precision valves and a nice Burkert 6011 Solenoid Valve or similar

Attachments

-

Screenshot_20230202_171748_Samsung Internet.jpg84.3 KB · Views: 35

Screenshot_20230202_171748_Samsung Internet.jpg84.3 KB · Views: 35 -

Screenshot_20230202_171716_eBay.jpg86.4 KB · Views: 28

Screenshot_20230202_171716_eBay.jpg86.4 KB · Views: 28 -

Screenshot_20230202_171641_eBay.jpg131 KB · Views: 31

Screenshot_20230202_171641_eBay.jpg131 KB · Views: 31 -

Screenshot_20230202_171405_Samsung Internet.jpg82.6 KB · Views: 33

Screenshot_20230202_171405_Samsung Internet.jpg82.6 KB · Views: 33 -

Screenshot_20230202_171310_Samsung Internet.jpg67.7 KB · Views: 35

Screenshot_20230202_171310_Samsung Internet.jpg67.7 KB · Views: 35 -

Screenshot_20230202_171049_Gallery.jpg41.8 KB · Views: 33

Screenshot_20230202_171049_Gallery.jpg41.8 KB · Views: 33

Quick question can we attach fittings directly to our metering valves such as SS-4-E or do we need the tube adapter fittings? I don't see why we would just want to verify before over purchasing parts

- Joined

- Jan 3, 2018

- Messages

- 834

- Reaction score

- 699

I am not familiar with the E designation. According to their on-line catalog all of the fine flow S series metering valves only come with tubing fittings so you would need adapters. I would be looking for the 1/8" SS-SS2 for a straight pattern or SS-SS2-A for the angle pattern. I prefer the 1/8" fittings. An SS4 will be 1/4". The larger flow M series valves are available with 1/8" NPT end connections.

https://www.swagelok.com/downloads/webcatalogs/en/ms-01-142.pdf

https://www.swagelok.com/downloads/webcatalogs/en/ms-01-142.pdf

I plan on using 1/4 metering valves my only 1/8 fittings will be attaching to the noid. I know they come with the tube fittings but those simply screw onto the valve and allow for a different connection type however I'm curious of the tube fittings are a different diameter to slow the flow or something if not my theory is a standard female fitting could connect directly to either or both sides of the valves without the need for the tube fittings. I may just try and see whit goes vs using the more expensive tube fittings

I know this is an old thread, but would you happen to have a picture of your splitter setup and the fitting parts you used? Was thinking about building my own CO2 system to supply three freshwater tanks, similar to what you're doingYou should just need two needle valves and two bubble counters with the necessary piping tees and other fittings to make a manifold. Assuming you can accept both tanks having the same CO2 on/off schedule you would only need one solenoid valve. Otherwise, you would want two of those as well.

They make splitter valve manifolds with up to about 6 needle valves in a spider pattern. You can connect the tubing to the outlet. You can find them online. I use one to supply two of my freshwater tanks from a single regulator and solenoid and they work well but I keep my operating pressure closer to 15 psi. They might be difficult to control at 50 psi depending on how man bubbles you want. The needle valve is not as precise as a Swagelok needle valve, but they are a lot cheaper. That should be a very good regulator capable of turning down much lower than 50 psig if you need to. You do have to purchase separate bubble counters. I have used the Fluval units for this. They are easy because they can just be inserted into the tubing anywhere, although I built one into each of my DIY PVC Griggs reactors with a short vertical section of 1/2" clear PVC in the CO2 injection port that I like better because they do not have to be refilled with fluid. Obviously, this would not work with a diffuser and then I would probably just use the Fluval bubble counters but I much prefer a Griggs reactor over a diffuser as there is no maintenance on them. I have never used the metallic bubble counters that mount directly onto the piping.

The saltwater calcium reactors have a much lower bubble rate than a planted tank system, so you will see a lot of recommendations for very fine needle valves on this site that really are not necessary on a typical freshwater tank.

- Joined

- Jan 3, 2018

- Messages

- 834

- Reaction score

- 699

I know this is an old thread, but would you happen to have a picture of your splitter setup and the fitting parts you used? Was thinking about building my own CO2 system to supply three freshwater tanks, similar to what you're doing

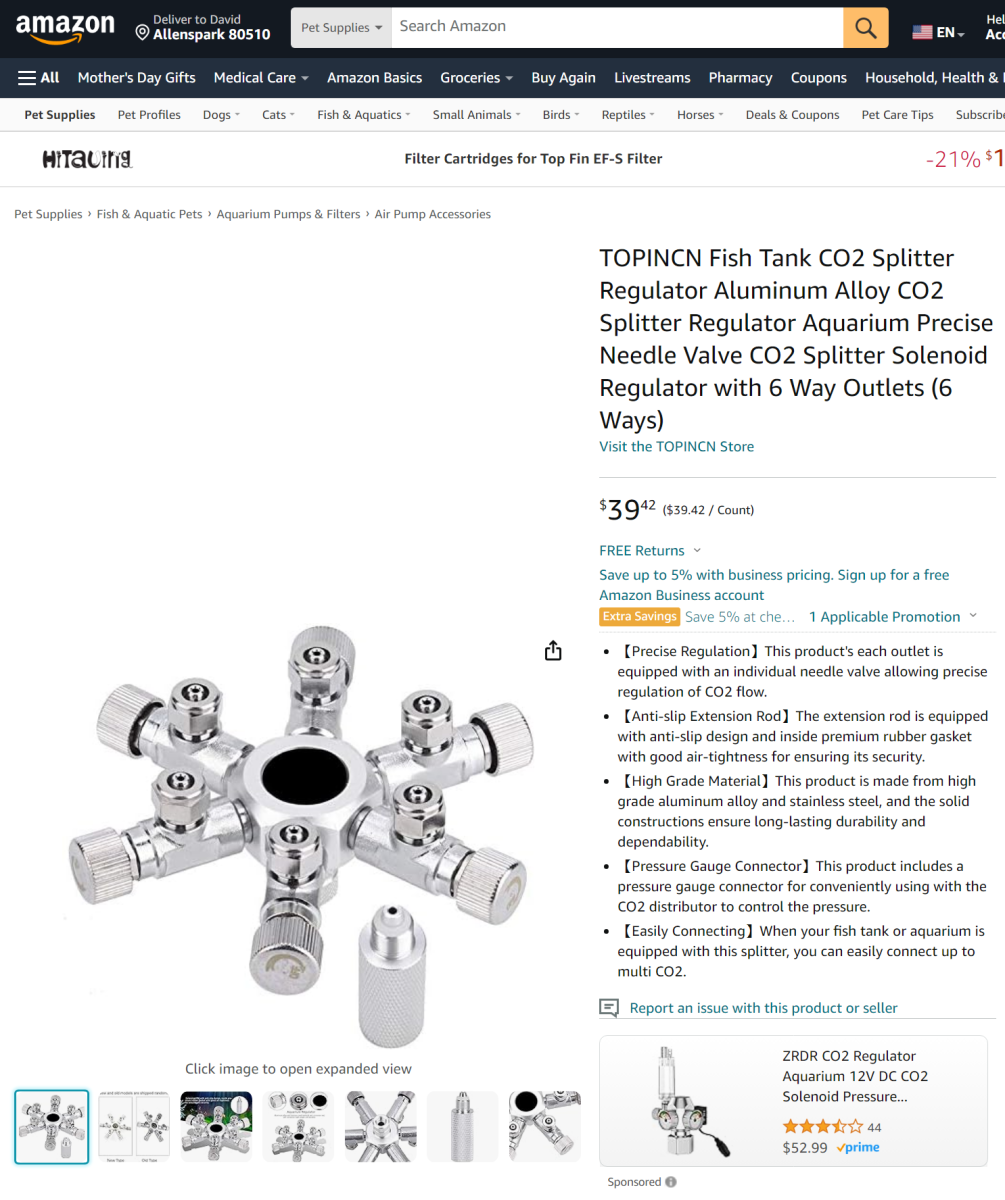

This is the type of splitter I used. I just found it in a LFS. There are ones with fewer connections. I just wanted to have one that had a threaded inlet and not air line because of the pressure. I think it is 1/8" NPT.

The pictures are not great because it is in a congested area, but I just have a cheap beer type single stage regulator with a solenoid. It is an old system I bought in the early 90's. I just used brass piping and fittings from Home Depot or Lowes to fit it up with an elbow to turn it horizontally. I have Fluval bubble counters and dual check valves in the air line coming from the valve manifold, but I really use the clear PVC bubble counters I built into the injection port of my DYI Griggs PVC CO2 reactor. I really like the Griggs I made from 3" PVC and can provide details if you are interested.

I have found that these type of valve manifolds give adequate control for FW planted tanks becasue the bulb rates are pretty high. I can easily adjust these to 1 bubble every second with 15 psig supply pressure which is about as low as I can go with my cheap single stage regulator.

This is the type of splitter I used. I just found it in a LFS. There are ones with fewer connections. I just wanted to have one that had a threaded inlet and not air line because of the pressure. I think it is 1/8" NPT.

The pictures are not great because it is in a congested area, but I just have a cheap beer type single stage regulator with a solenoid. It is an old system I bought in the early 90's. I just used brass piping and fittings from Home Depot or Lowes to fit it up with an elbow to turn it horizontally. I have Fluval bubble counters and dual check valves in the air line coming from the valve manifold, but I really use the clear PVC bubble counters I built into the injection port of my DYI Griggs PVC CO2 reactor. I really like the Griggs I made from 3" PVC and can provide details if you are interested.

I have found that these type of valve manifolds give adequate control for FW planted tanks becasue the bulb rates are pretty high. I can easily adjust these to 1 bubble every second with 15 psig supply pressure which is about as low as I can go with my cheap single stage regulator.

This is very helpful, I appreciate it! I'm weighting the pros and cons of a CO2 system with a single solenoid and three individual needle valves vs a splitter. I was worried about the control you have with the splitter but from your experience it seems like this is a non issue. The splitter is also 1/4 of the cost of the three needle valves. Would love to see your Griggs system. I'm very new to all of this but have really enjoyed researching and learningThis is the type of splitter I used. I just found it in a LFS. There are ones with fewer connections. I just wanted to have one that had a threaded inlet and not air line because of the pressure. I think it is 1/8" NPT.

The pictures are not great because it is in a congested area, but I just have a cheap beer type single stage regulator with a solenoid. It is an old system I bought in the early 90's. I just used brass piping and fittings from Home Depot or Lowes to fit it up with an elbow to turn it horizontally. I have Fluval bubble counters and dual check valves in the air line coming from the valve manifold, but I really use the clear PVC bubble counters I built into the injection port of my DYI Griggs PVC CO2 reactor. I really like the Griggs I made from 3" PVC and can provide details if you are interested.

I have found that these type of valve manifolds give adequate control for FW planted tanks becasue the bulb rates are pretty high. I can easily adjust these to 1 bubble every second with 15 psig supply pressure which is about as low as I can go with my cheap single stage regulator.

Similar threads

- Price: 250

- Shipping Available

- Replies

- 1

- Views

- 483

- Replies

- 10

- Views

- 948

- Replies

- 0

- Views

- 234