Ok so I’m getting a ton of PMs I can’t possibly reply to about help in designing T-slot stands using affordable t-slot products from zyltech.com I have no affiliation with zyltech (I believe they are actually more of a 3d printing company than T-slot supplier) but have found them to have great pricing when it comes to T-slot products.

Thought id just start a thread with some general info and where people can ask a question that can prove helpful to others. Disclaimer: I ain't responsible for nothin y'all design/build, yada yada yada...

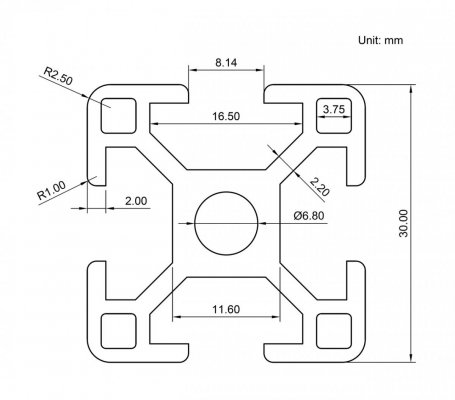

These are the 3030 bars I use/suggest for a majority of tanks:

Aluminum Extrusion - 3030 T Slot - ZYLtech Engineering, LLC

www.zyltech.com

www.zyltech.com

3030 (30mm x 30mm) can support A LOT of weight, especially when braced at intervals. I wouldn’t hesitate to use to for something up to around 200 gallons with braces every 18-24in or so.

For larger tanks, or if you just want something bulkier you could go bigger diameter, but I don’t have experience with the thicker bars, and its likely going to be overkill. Principles should be the same though, adjusting measurements for the larger bar diameter.

I would only use 2020 bar for something like a smaller nano where you really want a low profile. The 2020 bar is much smaller in diameter than 3030.

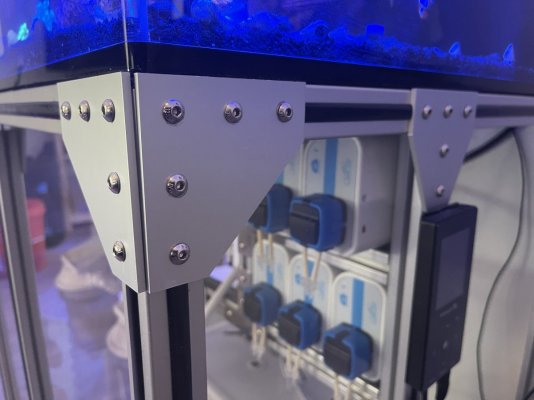

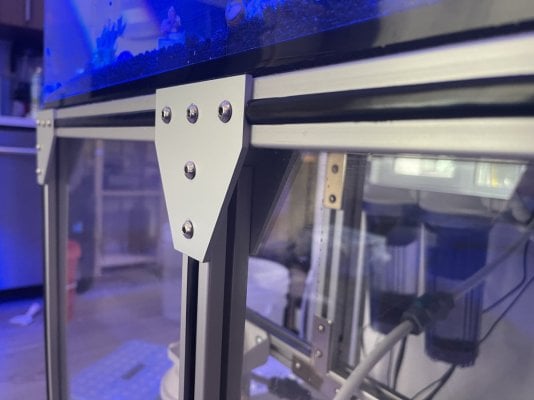

You will also need plates or brackets to form the joints. The simplest ones to use (without precise machining, which can just be installed by hand) are:

90 Brace/Angle Bracket

https://www.zyltech.com/12x-90-30mm-aluminum-brace-angle-bracket-for-3030-extrusion-black/

Joining Plates

https://www.zyltech.com/3030-90-degree-t-joining-plate-black/

L Type Inside Bracket

https://www.zyltech.com/t-slot-l-type-90-degree-3030-inside-bracket-12-pack/

When designing your stand, you will have to allow for a bracket at each point. The 90 Brace/Angle Brackets are by far the easiest to use, since they can be used at any slot joint without too much confusion or adjustment for bar diameter.

Along with brackets and bars, you will need (for 3030 bar) M5 Hammer Nuts and M5 Bolts. The bolts secure the bracket to the bar with force as you tighten then down. Zyltech offers a nice package that includes 10 1m bars along with some corner brackets and nuts/bolts

https://www.zyltech.com/3030-t-slot-30mm-aluminum-extrusion-kit-10x-1m-angle-brackets-screws-nuts/

It is important to remember you need to purchase brackets/plates specifically for the diameter bar you are using, a 2020 bracket will not work on a 3030 bar. Likewise M3 screws (for 2020) will be too small for 3030 rail - so double check when ordering that all your products are for the designated bar you use

You can also purchase brackets and bars and stuff on other websites like Amazon, they are all pretty universal as long as they are the correct size - I just find that Zyltech generally has good pricing compared to other vendors.

Zyltech also offers a custom cut service that I use - I find they can cut the bar more accurately then I can on my saw. Its $1.50 a cut, you just add the length to each cut you purchase.

https://www.zyltech.com/aluminum-extrusion-custom-cut-service/

When constructing your stand, you will want to do so in metric (MM) since all the bars are measured in metric. You can easily convert IN to MM using google or other conversion websites.

Those are the basics! If you have application-specific questions, post with a drawing and dimensions and I'll weigh in with my input.

Good luck with your build!

Last edited: