Made it back from my "To Short Vacation" LOL

Lets get back to the build.

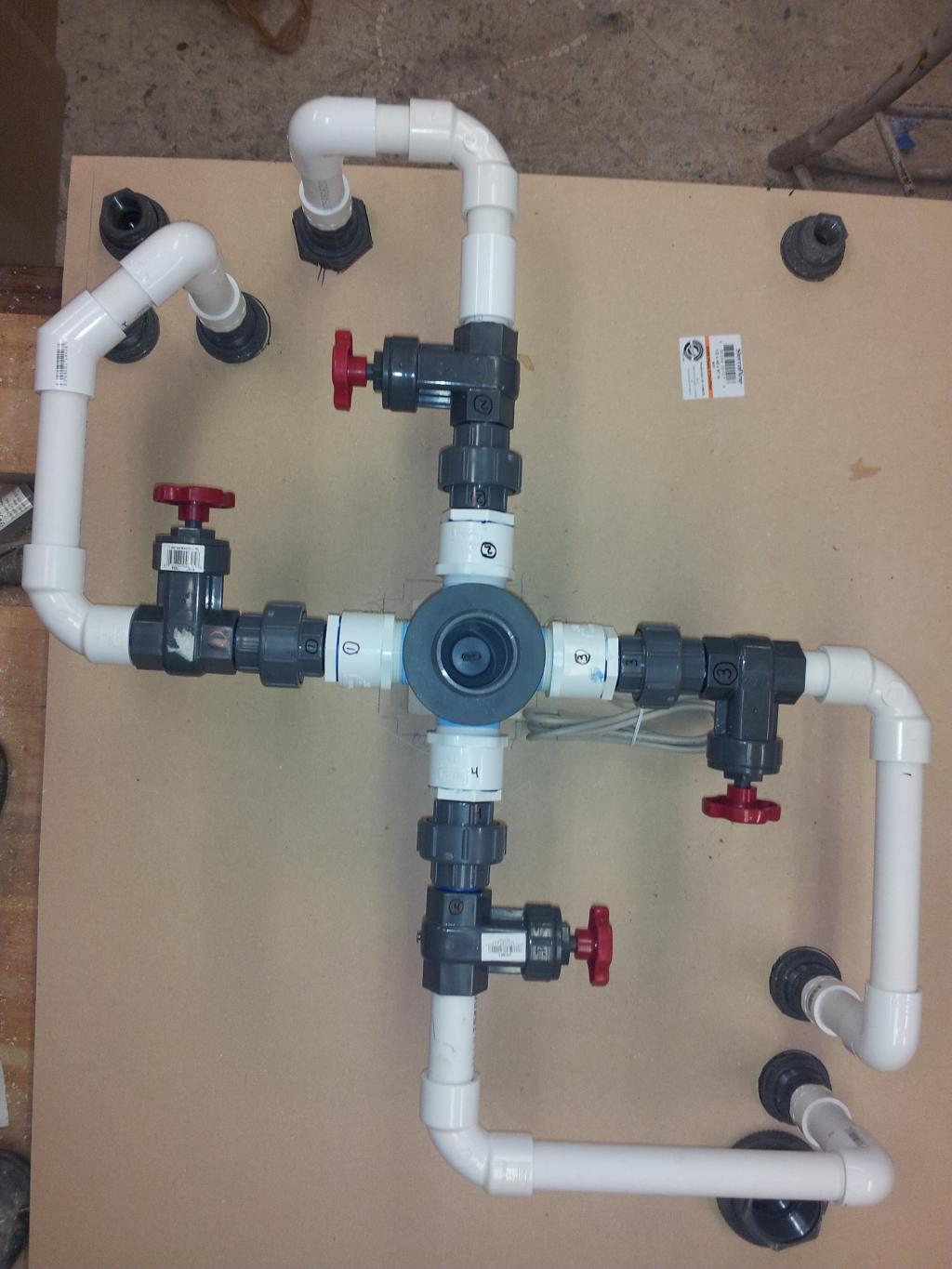

So with a closed loop flow in this tank, I need to know how and where the flow needs to be. That will all depend on the rock work.

So needless to say I have started the rock work before I have drilled the bottom of the tank. I ordered 70 lbs of tonga for the main structure. I need to exstend some of the simple long rocks to the heavy base of the structure. I use a 4'' grinder and a dremel to help aid in the connections of the rock. When I get to the point where the rock is assembled in the tank (just before the water) I will use a 2 part epoxy to help hold the rock in place , along with the white zip ties.

This is how I will prep all the tonga joints.

Mark the rock to a flat

Cut it with the grinder

Make a slot for the zip tie( dremel work)

Lets get back to the build.

So with a closed loop flow in this tank, I need to know how and where the flow needs to be. That will all depend on the rock work.

So needless to say I have started the rock work before I have drilled the bottom of the tank. I ordered 70 lbs of tonga for the main structure. I need to exstend some of the simple long rocks to the heavy base of the structure. I use a 4'' grinder and a dremel to help aid in the connections of the rock. When I get to the point where the rock is assembled in the tank (just before the water) I will use a 2 part epoxy to help hold the rock in place , along with the white zip ties.

This is how I will prep all the tonga joints.

Mark the rock to a flat

Cut it with the grinder

Make a slot for the zip tie( dremel work)