Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

210 Gallon Aquarium Help

- Thread starter cookiehouse79765

- Start date

- Tagged users None

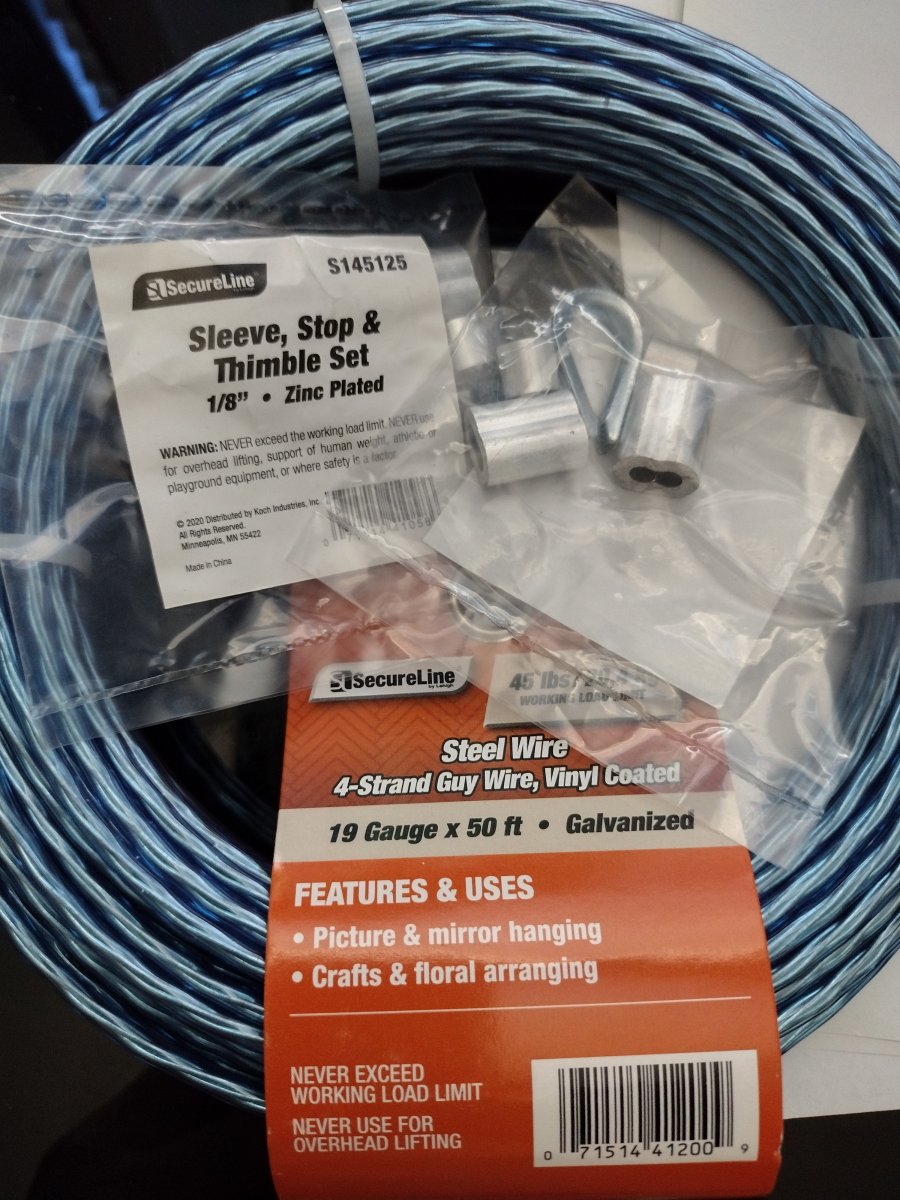

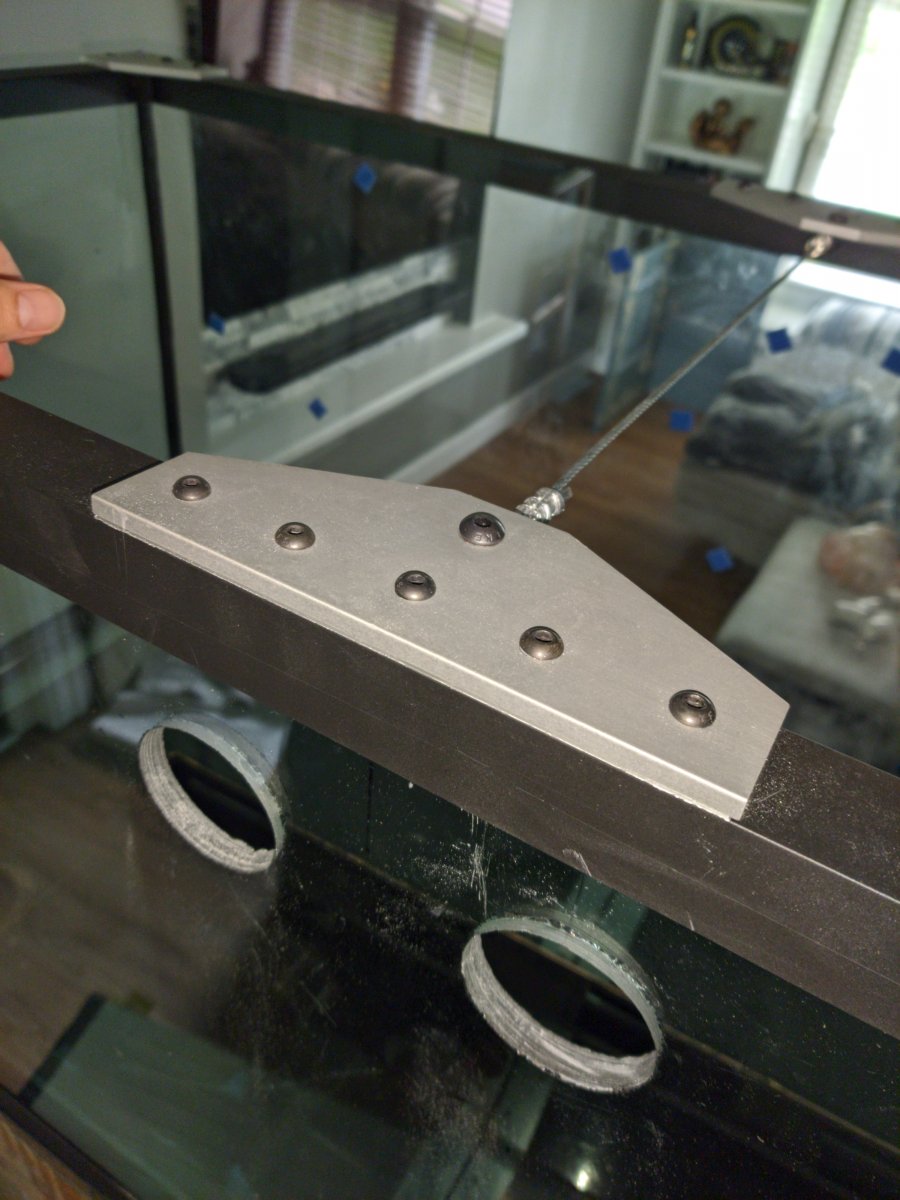

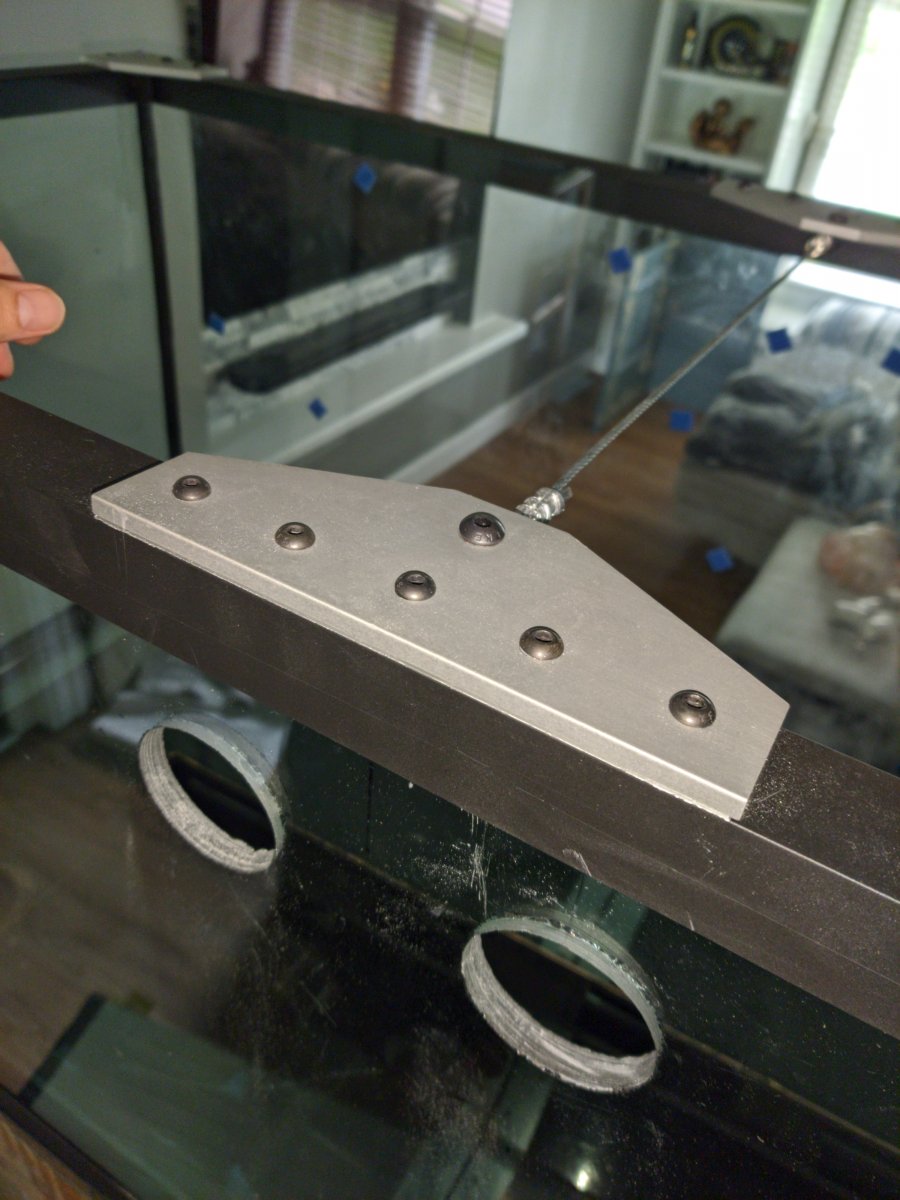

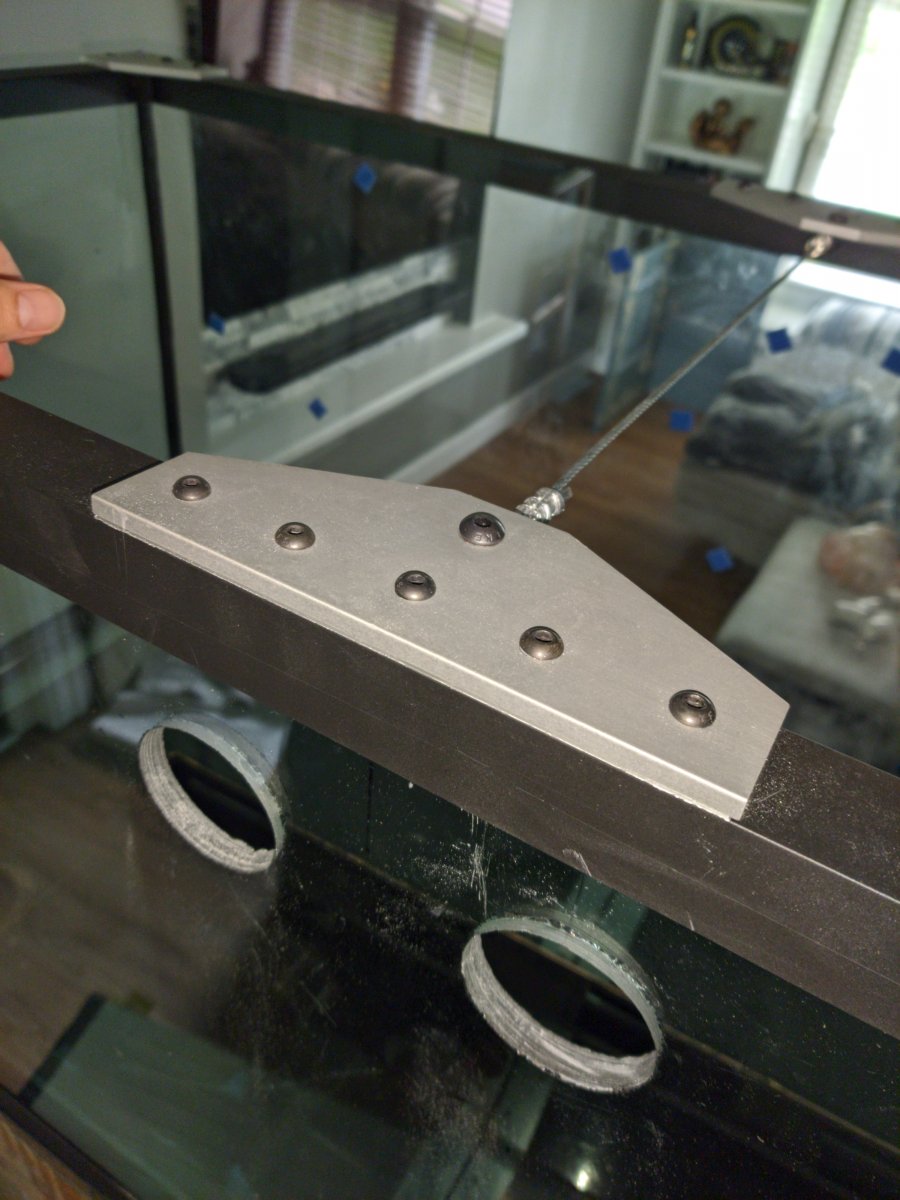

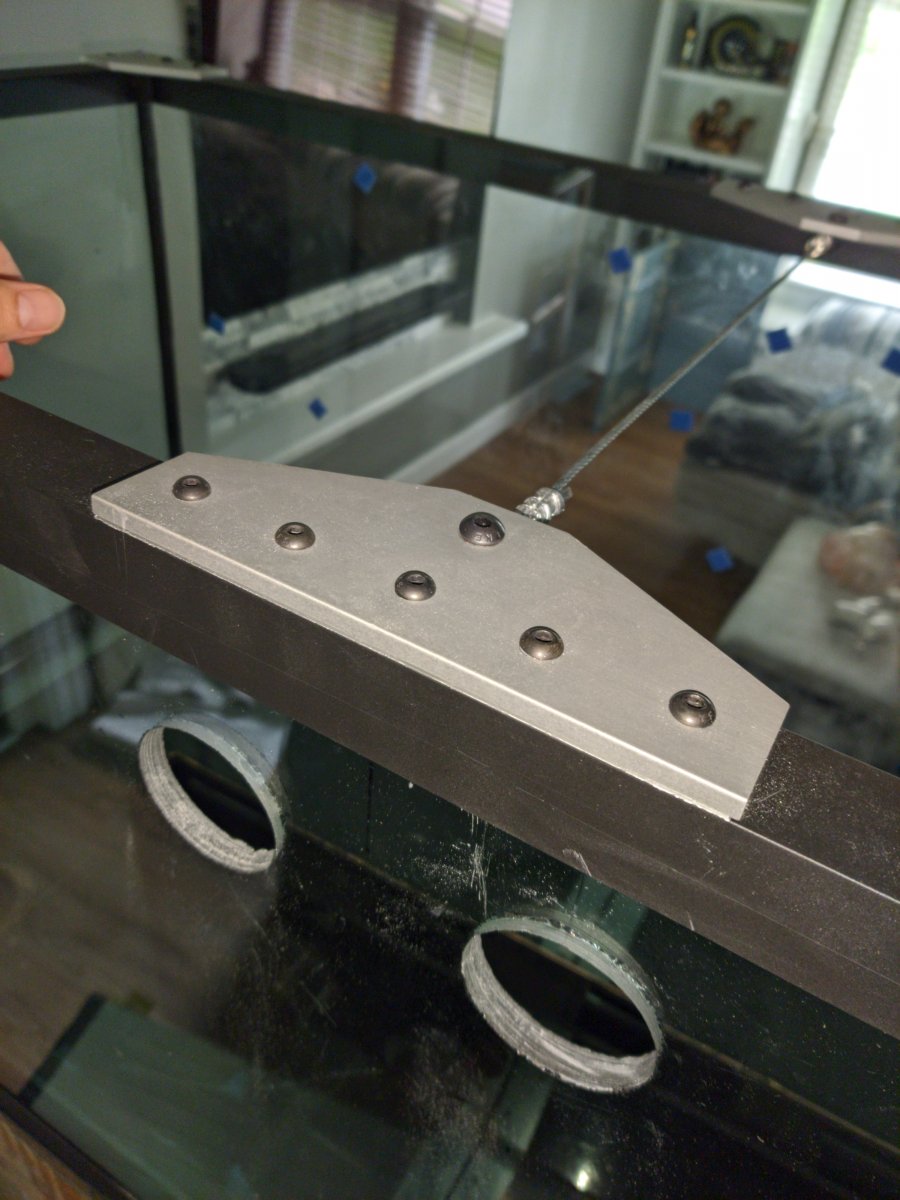

I've done it a few ways... The easiest is with a stop sleeve (need crimping tool) and stainless steel bolt & nut. Simply crimp the wire and insert bolt into joining plate. I no longer use "buttons" on top of the joining plates since the were decorative anyway and I've switched to a coated steel wire.Few questions if you don't mind. What different ways do you connect the cables, which do you prefer, and do you have any close up pictures of how you have the cables connected?

Thank you

Just a heads up, this isn't a DIY weekend warrior project. I usually get the tanks in rough shape, break them down, clean, measure cut, measure and cut again, drill, caulk, listen to wife complain there is no room in the garage etc. From start to finish it takes over a month sometimes two. In the end you can have a custom tank and save a couple grand if you don't mind the work. I've built one tank where it has a built in drain, turn a gate value and it drains 60g. in a few minutes making water changes a breeze. One of these days I'll add a build to my profile.

Good luck on your build and happy reefing.

- Joined

- Feb 4, 2020

- Messages

- 11

- Reaction score

- 7

Thank you very much.I've done it a few ways... The easiest is with a stop sleeve (need crimping tool) and stainless steel bolt & nut. Simply crimp the wire and insert bolt into joining plate. I no longer use "buttons" on top of the joining plates since the were decorative anyway and I've switched to a coated steel wire.

Just a heads up, this isn't a DIY weekend warrior project. I usually get the tanks in rough shape, break them down, clean, measure cut, measure and cut again, drill, caulk, listen to wife complain there is no room in the garage etc. From start to finish it takes over a month sometimes two. In the end you can have a custom tank and save a couple grand if you don't mind the work. I've built one tank where it has a built in drain, turn a gate value and it drains 60g. in a few minutes making water changes a breeze. One of these days I'll add a build to my profile.

Good luck on your build and happy reefing.

Hi

I know this is an old thread but my trim on bottom tank is cracked. How did you do bottom? Angle around held together how? Cross pieces on bottom are? Thanks so much!!

I know this is an old thread but my trim on bottom tank is cracked. How did you do bottom? Angle around held together how? Cross pieces on bottom are? Thanks so much!!

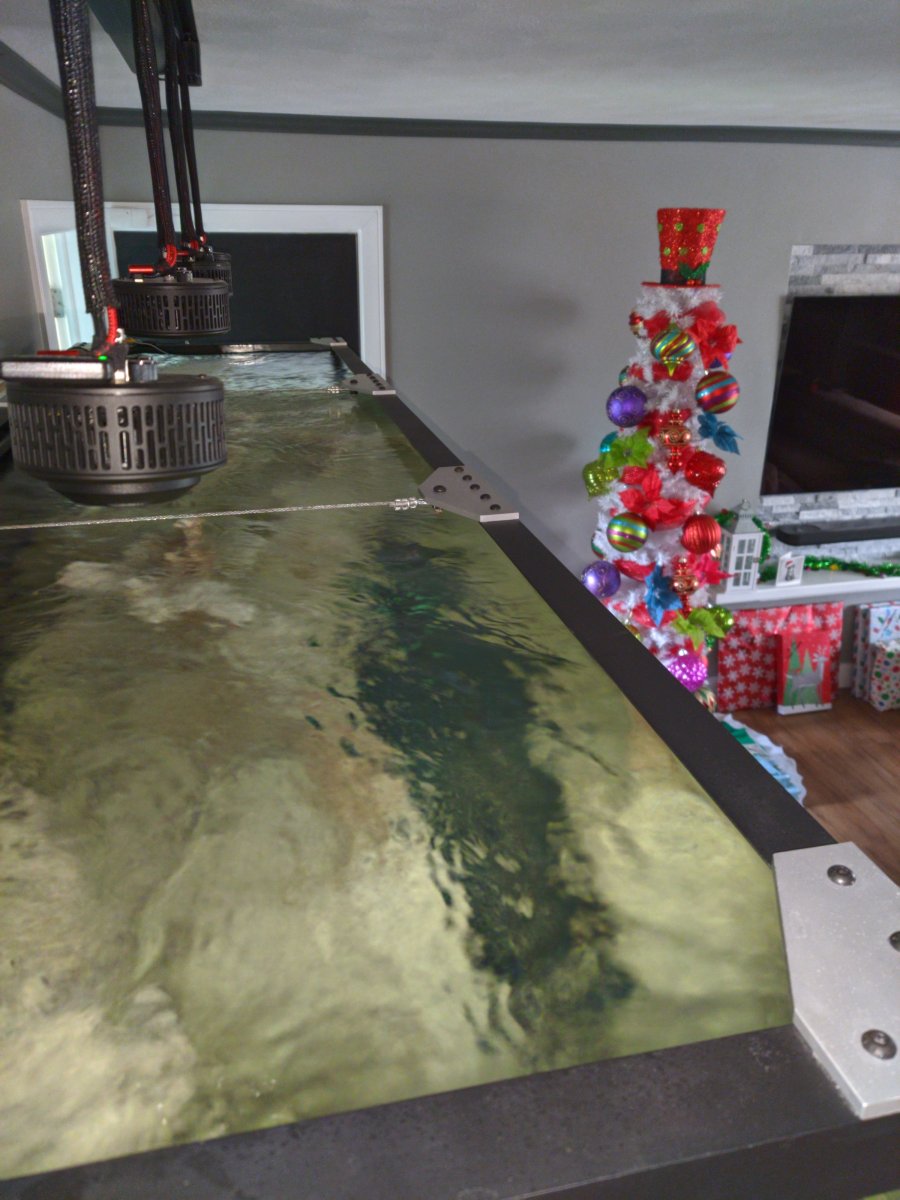

A few shots from different builds... Cant quite remember exactly what I used but something like this. Strap Tie Then the angle bars sit on held with JB Weld (metal bond) The straps along the edge are just to match the height of the cross straps. Hope this gives you some insight.

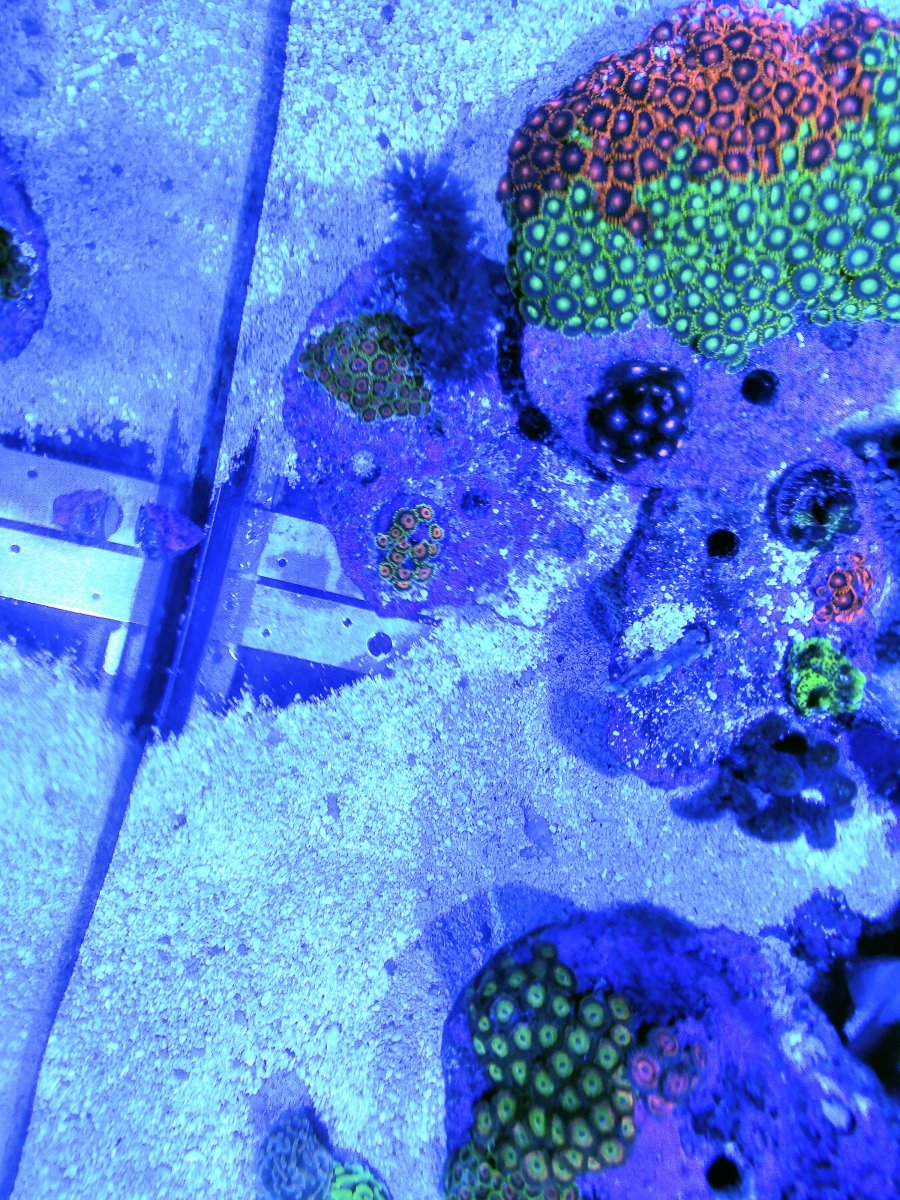

Tried to do a top shot for you just a few minutes ago...

Tried to do a top shot for you just a few minutes ago...

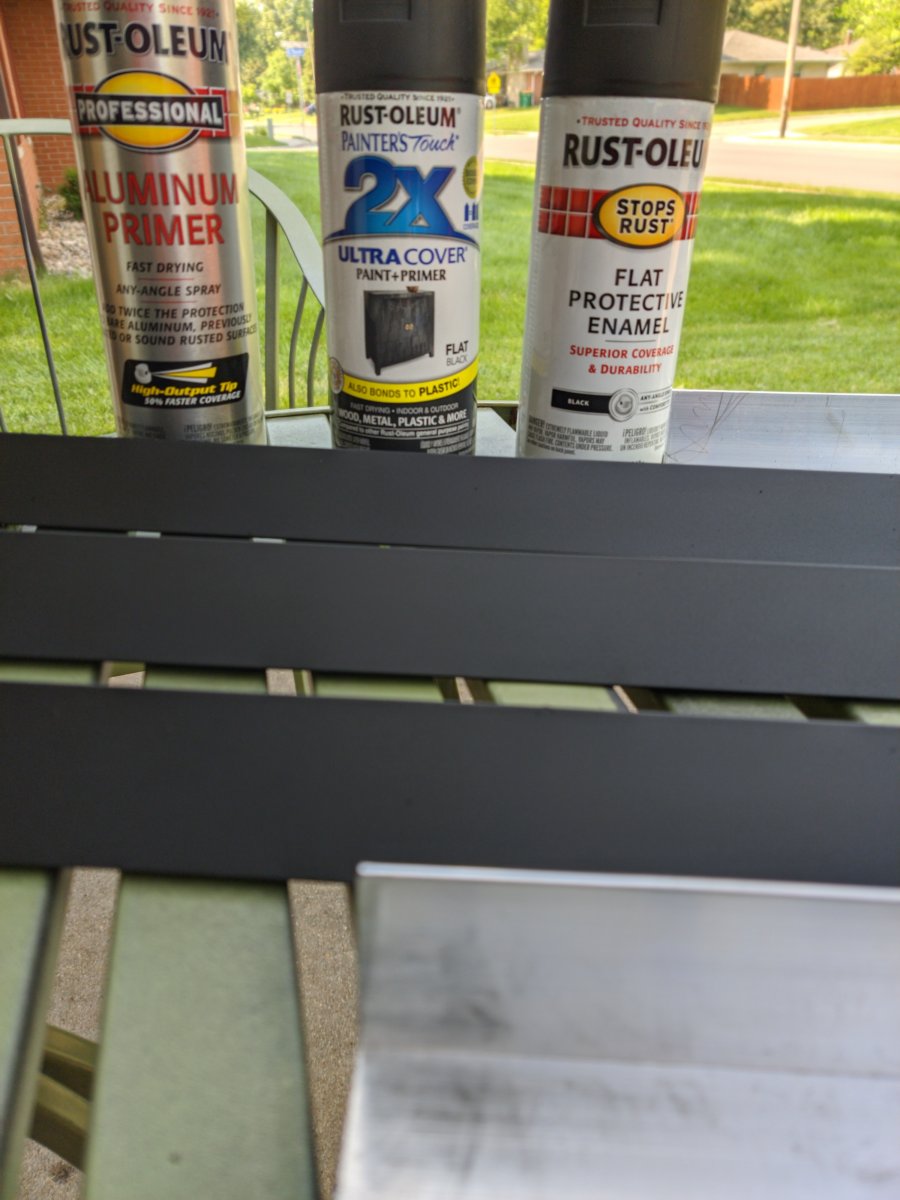

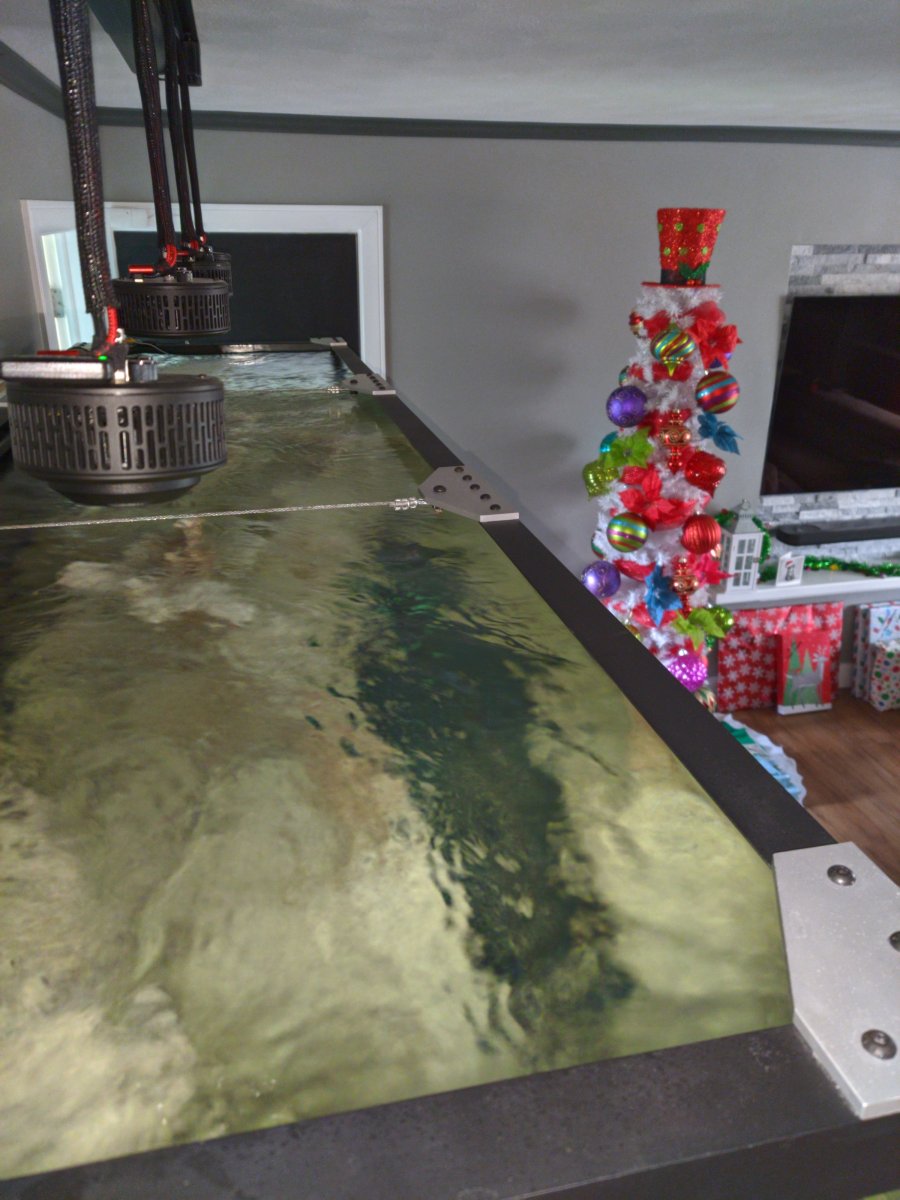

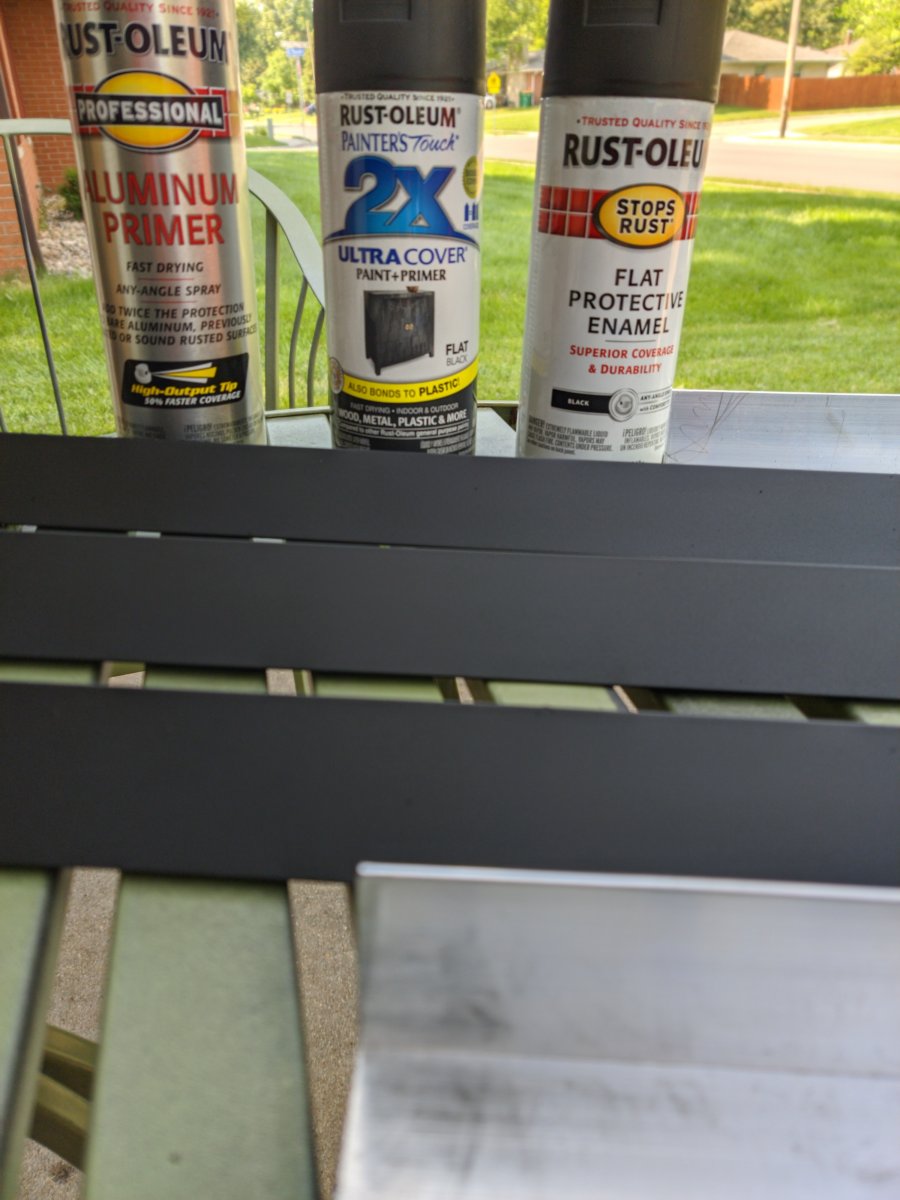

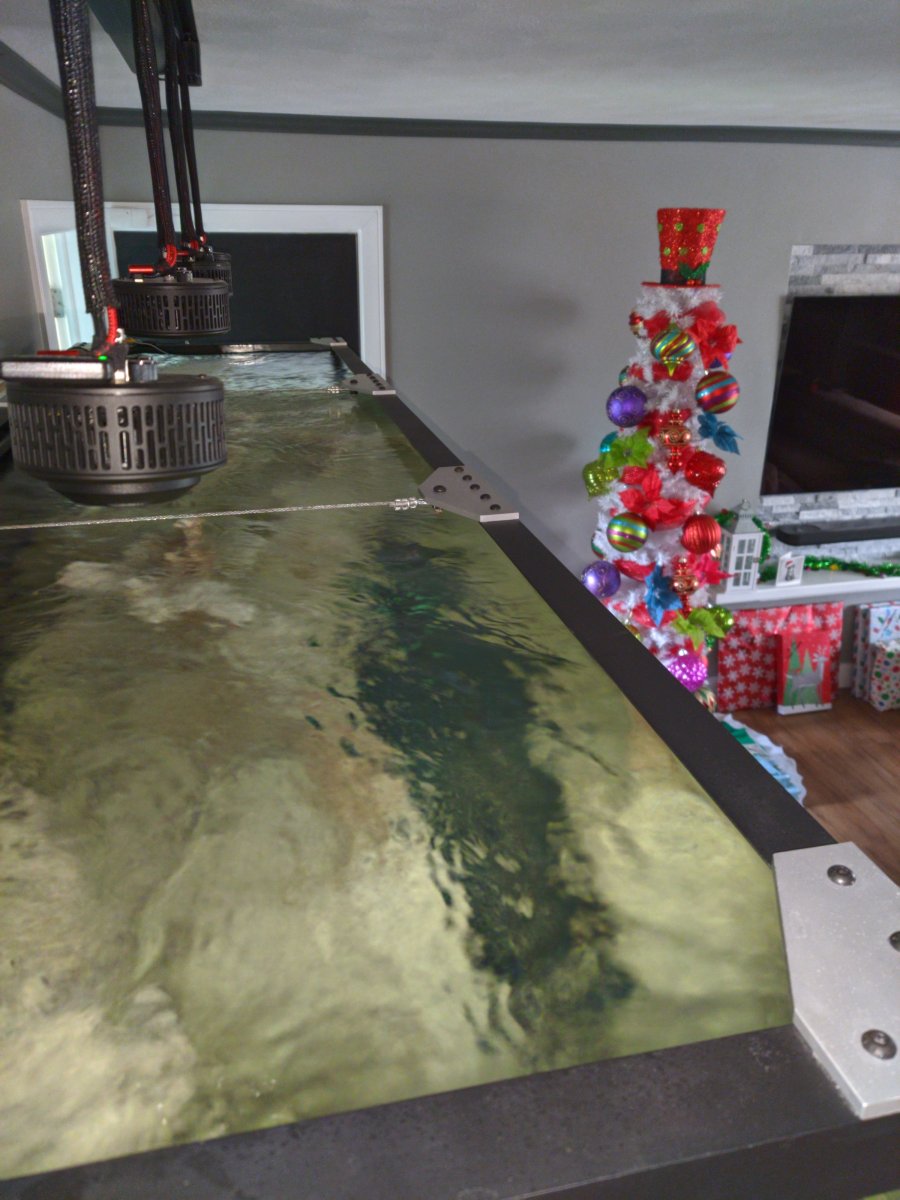

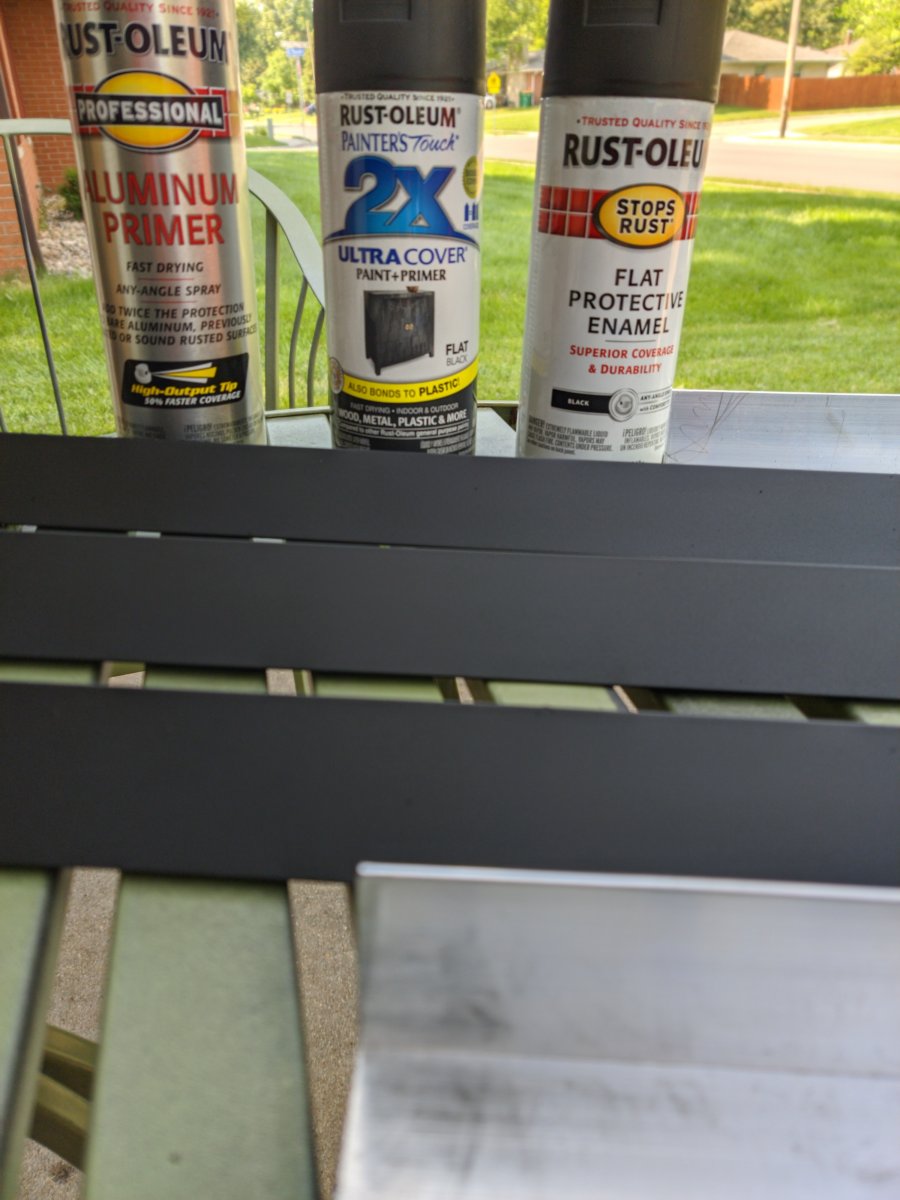

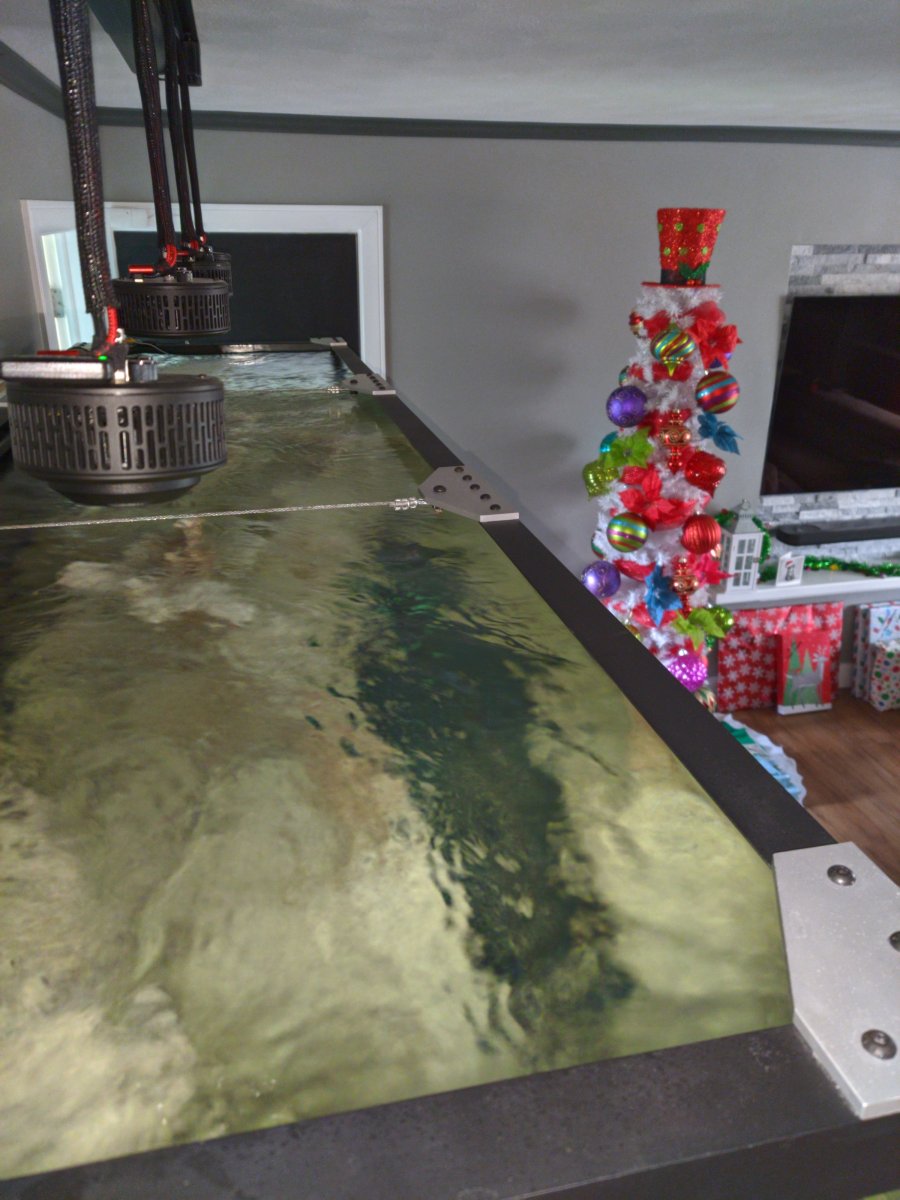

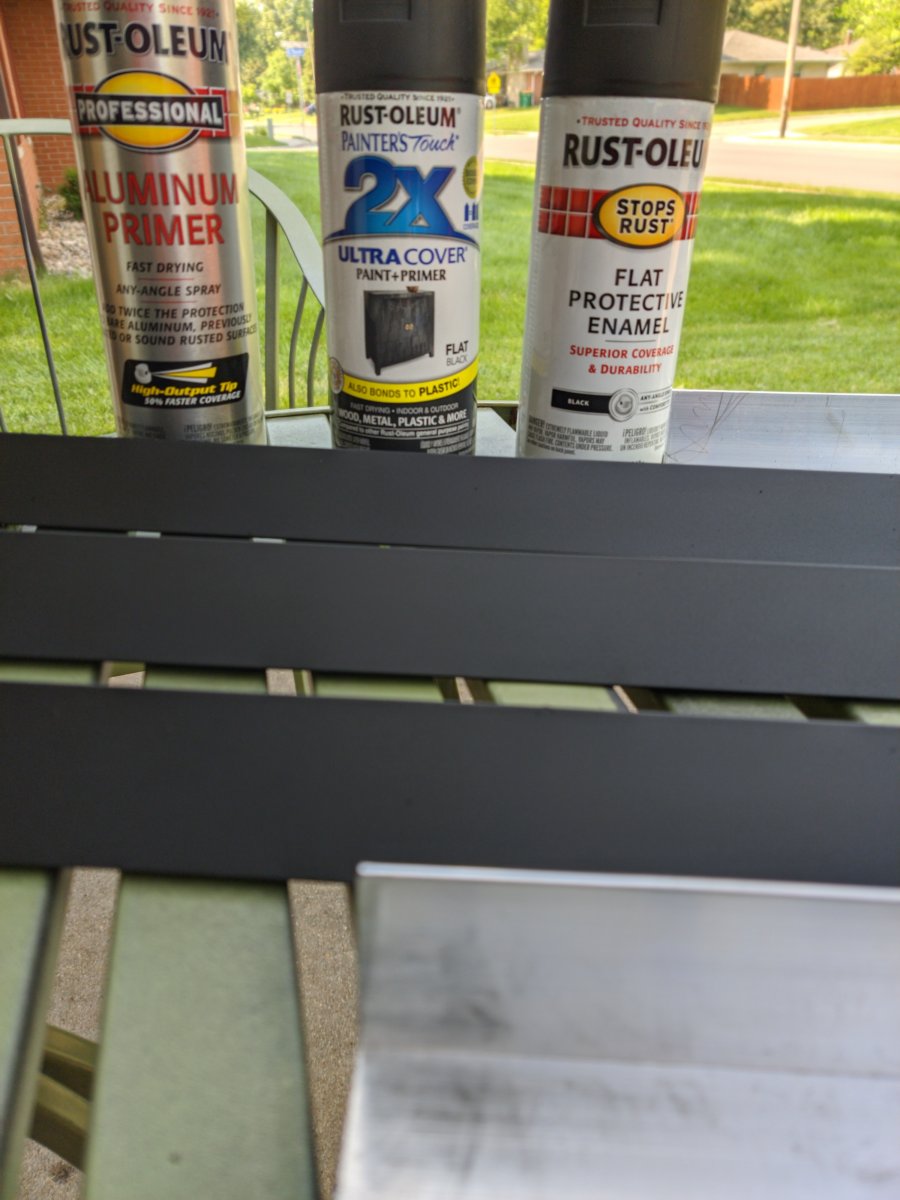

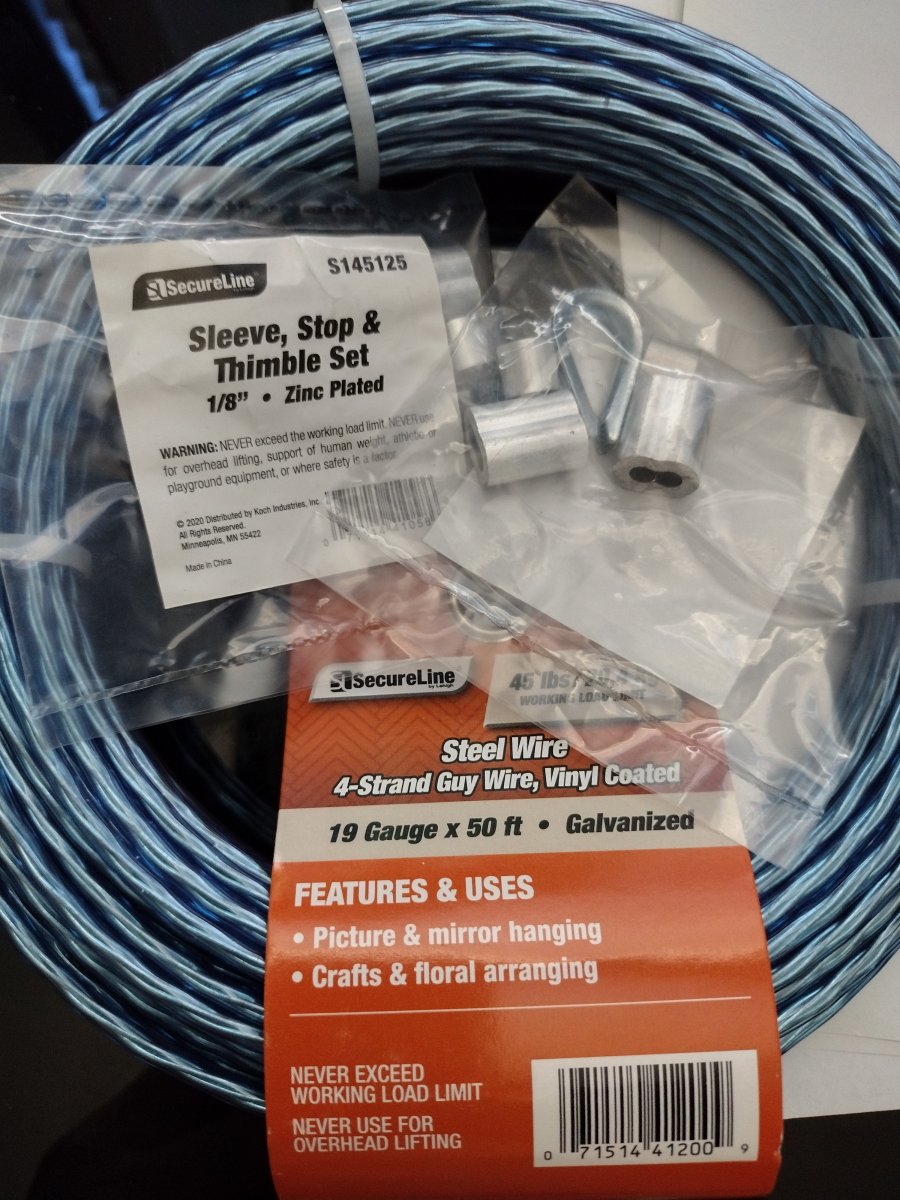

Sorry to hijack this butEuro brace is an option, I think cables and L channel give the tank a more modern/industrial look. Not to mention much easier to obtain and cut material. Aluminum channels can be found at any hardware store... Aluminum Angle Bar I usually reseal large tanks 6ft or larger, depending on the size tank they have different lengths and thickness. As for the cross braces... Galvanized Steel Cable Wire Rope works well, again different gauges of wire and different lengths. There are kits you can buy but there is a section were they will cut the individual gauge and length for you. Stay away from the sealed Stainless Steel Vinyl Coated Wire because its difficult to work with. Joining plates are used to attach the cables and L angles together, again different sizes, shapes and thickness. I use J-B Weld Professional to adhere the joining plates to the L angles. Anything over 3500 tensile strength, they have a quick weld that I have never tried but should work. I work on tanks in the garage so be check the proper temps when it can be applied. Then some generic black oxide, nickel or zinc tops (cant remember) non rust for the top of the plates. Purely aesthetics. Here are a few more photos. One of my own built tank using low iron glass. If this helps anyone give me thumbs up. Thanks

Sorry to hijack this but I just received a new 210g and I've been looking far and wide on how to reinforce my cracked braces and your builds are exactly what I've been looking for.Euro brace is an option, I think cables and L channel give the tank a more modern/industrial look. Not to mention much easier to obtain and cut material. Aluminum channels can be found at any hardware store... Aluminum Angle Bar I usually reseal large tanks 6ft or larger, depending on the size tank they have different lengths and thickness. As for the cross braces... Galvanized Steel Cable Wire Rope works well, again different gauges of wire and different lengths. There are kits you can buy but there is a section were they will cut the individual gauge and length for you. Stay away from the sealed Stainless Steel Vinyl Coated Wire because its difficult to work with. Joining plates are used to attach the cables and L angles together, again different sizes, shapes and thickness. I use J-B Weld Professional to adhere the joining plates to the L angles. Anything over 3500 tensile strength, they have a quick weld that I have never tried but should work. I work on tanks in the garage so be check the proper temps when it can be applied. Then some generic black oxide, nickel or zinc tops (cant remember) non rust for the top of the plates. Purely aesthetics. Here are a few more photos. One of my own built tank using low iron glass. If this helps anyone give me thumbs up. Thanks

I'm not sure how to send PMs since I

Sorry to hijack but I just got myself a 210g with cracked braces/frame and I've been looking everywhere for replacements but can't find any.Euro brace is an option, I think cables and L channel give the tank a more modern/industrial look. Not to mention much easier to obtain and cut material. Aluminum channels can be found at any hardware store... Aluminum Angle Bar I usually reseal large tanks 6ft or larger, depending on the size tank they have different lengths and thickness. As for the cross braces... Galvanized Steel Cable Wire Rope works well, again different gauges of wire and different lengths. There are kits you can buy but there is a section were they will cut the individual gauge and length for you. Stay away from the sealed Stainless Steel Vinyl Coated Wire because its difficult to work with. Joining plates are used to attach the cables and L angles together, again different sizes, shapes and thickness. I use J-B Weld Professional to adhere the joining plates to the L angles. Anything over 3500 tensile strength, they have a quick weld that I have never tried but should work. I work on tanks in the garage so be check the proper temps when it can be applied. Then some generic black oxide, nickel or zinc tops (cant remember) non rust for the top of the plates. Purely aesthetics. Here are a few more photos. One of my own built tank using low iron glass. If this helps anyone give me thumbs up. Thanks

I plan on doing what you've done with yours with the aluminum just over the existing bracing since it still has some structural integrity however I did have a question about the corner and center pieces. I believe you mentioned that you used JB weld to attached them to the L pieces however it also looks like you used rivets as well?

Rivets weren't used, just decorative caps from screws. (buttons) They filled the holes were the joining plates and angle bar meet. I've replaced the galvanized wire with a vinyl coated one. A little more difficult to deal with but not subject to corrosion. Have you tried to repair your frame? Possibly just mend the cracked pieces together? There are places that also make custom frames, might be cheaper with less work involved. Here a a couple links, hope it helps with your project. Custom Aquarium Frames & Broken Cross braceSorry to hijack this but

Sorry to hijack this but I just received a new 210g and I've been looking far and wide on how to reinforce my cracked braces and your builds are exactly what I've been looking for.

I'm not sure how to send PMs since I

Sorry to hijack but I just got myself a 210g with cracked braces/frame and I've been looking everywhere for replacements but can't find any.

I plan on doing what you've done with yours with the aluminum just over the existing bracing since it still has some structural integrity however I did have a question about the corner and center pieces. I believe you mentioned that you used JB weld to attached them to the L pieces however it also looks like you used rivets as well?

It's been a few years now how are these tanks holding up? I just got a bow front 150 gal with no top support. I'm planning on using your designs to build one.Euro brace is an option, I think cables and L channel give the tank a more modern/industrial look. Not to mention much easier to obtain and cut material. Aluminum channels can be found at any hardware store... Aluminum Angle Bar I usually reseal large tanks 6ft or larger, depending on the size tank they have different lengths and thickness. As for the cross braces... Galvanized Steel Cable Wire Rope works well, again different gauges of wire and different lengths. There are kits you can buy but there is a section were they will cut the individual gauge and length for you. Stay away from the sealed Stainless Steel Vinyl Coated Wire because its difficult to work with. Joining plates are used to attach the cables and L angles together, again different sizes, shapes and thickness. I use J-B Weld Professional to adhere the joining plates to the L angles. Anything over 3500 tensile strength, they have a quick weld that I have never tried but should work. I work on tanks in the garage so be check the proper temps when it can be applied. Then some generic black oxide, nickel or zinc tops (cant remember) non rust for the top of the plates. Purely aesthetics. Here are a few more photos. One of my own built tank using low iron glass. If this helps anyone give me thumbs up. Thanks

Still holding up no issues other than I got about 50 BTAs. Prices for material now is crazy. I used to buy Momentive RTV silicon for $11 a tube... last looked was about $38 a tube. I'm sure the L channel and glass has probably double in last few years.

Ok, so I have a brand new Marineland 180g that has never seen water.Rivets weren't used, just decorative caps from screws. (buttons) They filled the holes were the joining plates and angle bar meet. I've replaced the galvanized wire with a vinyl coated one. A little more difficult to deal with but not subject to corrosion. Have you tried to repair your frame? Possibly just mend the cracked pieces together? There are places that also make custom frames, might be cheaper with less work involved. Here a a couple links, hope it helps with your project. Custom Aquarium Frames & Broken Cross brace

I have it standing on its side right now while I finish building the stand.

This morning I noticed that one of the middle braces is cracked along the outside part of the frame into the middle Brace.

I called Marineland, they send me to local pet store, I called couple of LFS and the send me to glasscages.com, I called glass cages and they sent me to BRS, I called BRS and they sent me back to glass cages so now I'm here.

After reading the entire thread, and considering that the tank is brand new...

Do you think using JB Weld on the cracks would be enough to hold together?

Applying anything adhesive to the cracks won't work. You will need to completely replace the brace or brace the brace if that makes sense. This video might give you an idea.Ok, so I have a brand new Marineland 180g that has never seen water.

I have it standing on its side right now while I finish building the stand.

This morning I noticed that one of the middle braces is cracked along the outside part of the frame into the middle Brace.

I called Marineland, they send me to local pet store, I called couple of LFS and the send me to glasscages.com, I called glass cages and they sent me to BRS, I called BRS and they sent me back to glass cages so now I'm here.

After reading the entire thread, and considering that the tank is brand new...

Do you think using JB Weld on the cracks would be enough to hold together?

Repair center brace

The Crack that it has its not across like the one in the video, it long ways...if that makes sense.Applying anything adhesive to the cracks won't work. You will need to completely replace the brace or brace the brace if that makes sense. This video might give you an idea.

Repair center brace

So technically it still holds together....

And it's not all the way thru.

Okay, my thought was the crack going the other way. In this case I think you will be fine just adding some JB Weld to the frame. They make it for plastics & in black. Good luck.

JB Weld for plastics

JB Weld for plastics

I was gonna use the clear one with a higher tensile strength but ill go with the black one instead thenOkay, my thought was the crack going the other way. In this case I think you will be fine just adding some JB Weld to the frame. They make it for plastics & in black. Good luck.

JB Weld for plastics

Thank you very much!

Ok, so I have a brand new Marineland 180g that has never seen water.

I have it standing on its side right now while I finish building the stand.

This morning I noticed that one of the middle braces is cracked along the outside part of the frame into the middle Brace.

I called Marineland, they send me to local pet store, I called couple of LFS and the send me to glasscages.com, I called glass cages and they sent me to BRS, I called BRS and they sent me back to glass cages so now I'm here.

After reading the entire thread, and considering that the tank is brand new...

Do you think using JB Weld on the cracks would be enough to hold together?

Marineland should be the place for you to get a replacement Marineland frame. We dont carry replacement Marineland parts.

you could try

Over The Edge

Industry Leader in Wholesale Plastic Aquarium Tank Frames,Aquarium frames,Aquarium Lighting and Iron Stands

www.aquariumframeswholesale.com

www.aquariumframeswholesale.com

the real challenge is a plastic frame on a tank of this size. We get many calls for replacement frames on these larger tanks. We dont build large tanks with plastic frames, thats why we dont stock them.

good luck.

Thank you for the reply.Marineland should be the place for you to get a replacement Marineland frame. We dont carry replacement Marineland parts.

you could try

Over The Edge

Industry Leader in Wholesale Plastic Aquarium Tank Frames,Aquarium frames,Aquarium Lighting and Iron Standswww.aquariumframeswholesale.com

the real challenge is a plastic frame on a tank of this size. We get many calls for replacement frames on these larger tanks. We dont build large tanks with plastic frames, thats why we dont stock them.

good luck.

I looked in the over the edge site and all I found was frames for up to 18"wides. Maybe I didn't look hard enough, idk.

What I really want to do is euro brace the tank and remove the top brace but I don't know if it's even possible with a Marineland.

Plus in my area, the only glass shop I found doesn't deal with glass thicker than a 1/4 inch.

Hi, i know this thread is old but I am entirely invested. Question, did you drill holes in the aluminum angles for the jointing plate's screws?

second question, how do you find the perfect length to cut the galvanized steel?

third question, can I spray the galvanized steel with protective enamel spray to avoid rust on the wires?

Thanks

second question, how do you find the perfect length to cut the galvanized steel?

third question, can I spray the galvanized steel with protective enamel spray to avoid rust on the wires?

Thanks

Hi, i know this thread is old but I am entirely invested. Question, did you drill holes in the aluminum angles for the jointing plate's screws?I've done it a few ways... The easiest is with a stop sleeve (need crimping tool) and stainless steel bolt & nut. Simply crimp the wire and insert bolt into joining plate. I no longer use "buttons" on top of the joining plates since the were decorative anyway and I've switched to a coated steel wire.

Just a heads up, this isn't a DIY weekend warrior project. I usually get the tanks in rough shape, break them down, clean, measure cut, measure and cut again, drill, caulk, listen to wife complain there is no room in the garage etc. From start to finish it takes over a month sometimes two. In the end you can have a custom tank and save a couple grand if you don't mind the work. I've built one tank where it has a built in drain, turn a gate value and it drains 60g. in a few minutes making water changes a breeze. One of these days I'll add a build to my profile.

Good luck on your build and happy reefing.

second question, how do you find the perfect length to cut the galvanized steel?

third question, can I spray the galvanized steel with protective enamel spray to avoid rust on the wires?

Thanks

I didn't drill any holes, just used expoxy to joint the plates to the rails. To cut the angle bars just use a miter saw with a metal blade. The galvanized wire won't rust since it's vinyl coated. I think I applied a little caulk on were I snipped the wire. Good luck on your build.Hi, i know this thread is old but I am entirely invested. Question, did you drill holes in the aluminum angles for the jointing plate's screws?

second question, how do you find the perfect length to cut the galvanized steel?

third question, can I spray the galvanized steel with protective enamel spray to avoid rust on the wires?

Thanks

Similar threads

- Price: 500

- Shipping NOT Available

- Replies

- 0

- Views

- 272

- Replies

- 5

- Views

- 223

- Replies

- 32

- Views

- 890