Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

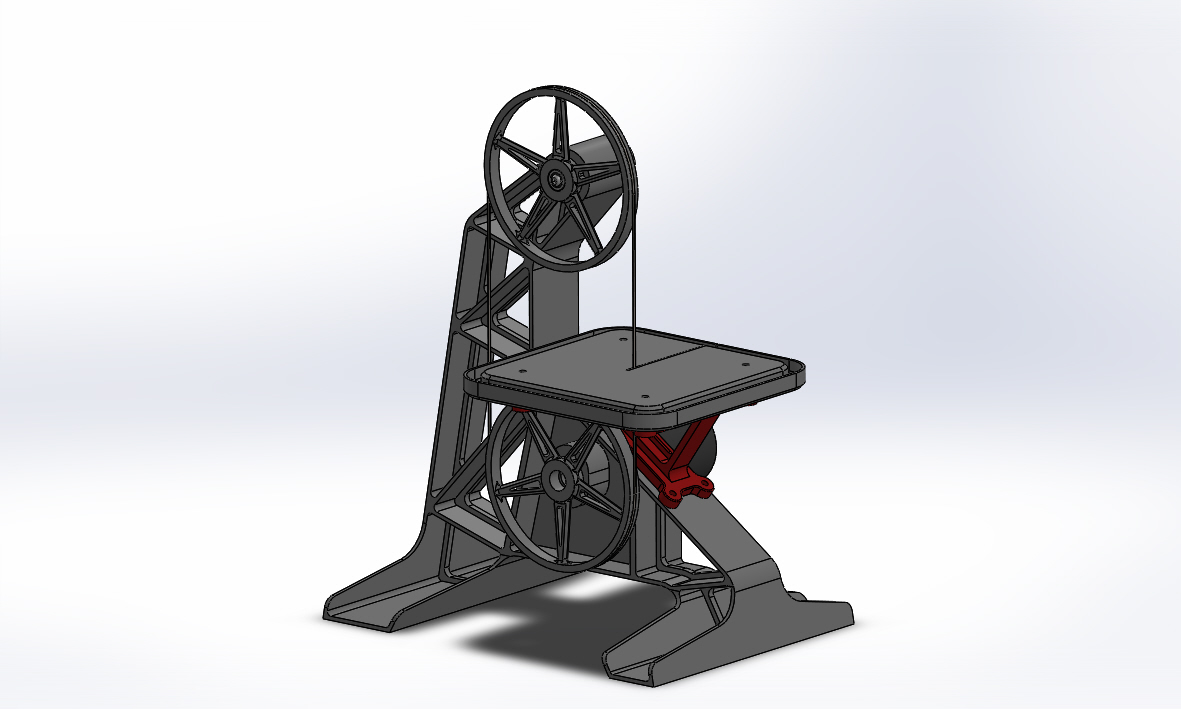

3D Printed Coral Bandsaw

- Thread starter 3D Reefin'

- Start date

- Tagged users None

Working on that now. The wheel travels on a slot, its adjusted by a screw with a hand knob at the end.What are using for a tensioner for the blade?

Quick question. Do your wheels have "tires" (thin rubber around them) or are they just plastic?

Very cool! What are the approximate dimensions? What will you be using for the motor?

Off the top of my head, roughly 20"H, footprint 14"x14"? I can get specifics once I check the model. the motor that I am looking at is a 50-70rpm 110v motor.

Quick question. Do your wheels have "tires" (thin rubber around them) or are they just plastic?

I like that concept better then the spring loaded design of the Inland.Working on that now. The wheel travels on a slot, its adjusted by a screw with a hand knob at the end.

woodcraft rockler , I was looking at harbor freight, little band saw w/ aluminum table might be for some without the skills to do a poor mans frag saw. Blade is 50. Give it a bath when done it may work.

Here are some update pics. Found some stainless bearings that may work in a saltwater application. Still under progress. Will be printing soon.

If you want to make a functional, "Steampunk?" tool you should think about ditching the band saw motor and adding either a pedal or hand crank to drive the blade. (Keep the sump space for the cooling pump.) Or maybe a highbred design with both features?

The difficulty with these saws that I have experienced is that speed control of the blade (generally one speed) doesn't allow for finessing the cutting process like old fashioned hand tools require/allow.

And don't forget to wear goggles, you can easily lose an eye to fragments, bacteria or palytoxin's during operation. Which reminds me, some older grinders had a clear glass or plexiglass shield to keep stuff from flying unto the operators face. That might be a nice addition.

Cool printer project!

Thanks for the pics. Does the blade slip or stop while you use it?

woodcraft rockler , I was looking at harbor freight, little band saw w/ aluminum table might be for some without the skills to do a poor mans frag saw. Blade is 50. Give it a bath when done it may work.

I try to stick to non-mechanical or electrical tools from HF, like hand tools for sacrificial use (modified tools). I will say though, their 20 ton press and their pallet jack are work horses, and good bang for your buck.

I have never had an issue yet, knock on woodThanks for the pics. Does the blade slip or stop while you use it?

I would definitely go with a variable speed motor!Off the top of my head, roughly 20"H, footprint 14"x14"? I can get specifics once I check the model. the motor that I am looking at is a 50-70rpm 110v motor.

If you want to make a functional, "Steampunk?" tool you should think about ditching the band saw motor and adding either a pedal or hand crank to drive the blade. (Keep the sump space for the cooling pump.) Or maybe a highbred design with both features?

The difficulty with these saws that I have experienced is that speed control of the blade (generally one speed) doesn't allow for finessing the cutting process like old fashioned hand tools require/allow.

And don't forget to wear goggles, you can easily lose an eye to fragments, bacteria or palytoxin's during operation. Which reminds me, some older grinders had a clear glass or plexiglass shield to keep stuff from flying unto the operators face. That might be a nice addition.

Cool printer project!

I am not trying to make a Steampunk tool. Just trying to get the most rigidity and use the least amount of material possible. I thought about using topology optimization for the frame, but it would look a bit funky.

I thought about doing a variable speed motor, but I am trying to keep this project under $100. DoAll saws have a neat variable pulley system, but I want to keep this design as simple and easy to clean as possible.

I would definitely go with a variable speed motor!

I'll do some research and see if I can find a variable speed motor for cheap.

A few thoughts:

* Have the drainage water go through a sock to collect 'bits'

* Have the drained water go through a charcoal filter, I believe that would help eliminate the palytoxin problems

And I second the eye shield.

* Have the drainage water go through a sock to collect 'bits'

* Have the drained water go through a charcoal filter, I believe that would help eliminate the palytoxin problems

And I second the eye shield.

I still have a lot of modeling to do. Guides, scrapers, water tray, etc are all on the list.

I also think I am going to change the spokes on the wheel. Not that big of a fan of the design.

Don't get me wrong, I know modeling is time consuming work and can take considerable time to work out details. I know the end product isn't always ideal to what you had in mind but your efforts are appreciated!

Also, waste water should be flushed right down a drain (like drainage over side of the sink and rinsed down). Simple is good

Don't get me wrong, I know modeling is time consuming work and can take considerable time to work out details. I know the end product isn't always ideal to what you had in mind but your efforts are appreciated!

Also, waste water should be flushed right down a drain (like drainage over side of the sink and rinsed down). Simple is good

Very time consuming. haha

Picked up my bearings today and the top wheel is printing.

Here is the new wheel design.

I love it!Here is the new wheel design.

Similar threads

- Replies

- 2

- Views

- 125

- Replies

- 1

- Views

- 171

- Replies

- 4

- Views

- 282

USA

Frag Racks, Shroom Cages, Egg Crate Legs, Skulls, Coral Trees, CUSTOM ITEMS // Orlando FL or Shipping available

- Price: $5 - $40

- Shipping Available

- Replies

- 2

- Views

- 166