Agreed and ender 3 with glass bed and upgraded extruder and you are good to go.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing thread

- Thread starter PurpleMonster

- Start date

- Tagged users None

Love my Ender 3. The only thing is the bed size, if you need to make larger objects then a CR-10S would be my choice...I had one and wish I still had it. I haven’t kept up but there is a CR-10S Pro which looks interesting.

Love my Ender 3. The only thing is the bed size, if you need to make larger objects then a CR-10S would be my choice...I had one and wish I still had it. I haven’t kept up but there is a CR-10S Pro which looks interesting.

Isn't the cr-10 just a big ender 3?

Isn't the cr-10 just a big ender 3?

The CR-10S has dual Z screws...the Pro has a lot of upgrades including an ABL sensor from what I have read

Amazon reviews aren’t too good on it though. I was looking st that prior to the PrusaThe CR-10S has dual Z screws...the Pro has a lot of upgrades including an ABL sensor from what I have read

I would love a prusa but a grand for a printer is a bit rich for me.

I will have about $350 in mine with all upgrades and I couldn't imagine at this point needing more unless it was a bigger print bed. And even then I wouldn't think that would get used that much more than what I build now.

I will have about $350 in mine with all upgrades and I couldn't imagine at this point needing more unless it was a bigger print bed. And even then I wouldn't think that would get used that much more than what I build now.

Amazon reviews aren’t too good on it though. I was looking st that prior to the Prusa

Yikes...yea the reviews don’t look good!

Agree with everyone else here - the Ender3 is a great choice for an under 500 3D printer. Its easy to setup and easy to upgrade.Quick question. I am looking to get a printer. Budget is about $500. What is best for reef stuff?

(I suspect this is like asking what light/salt to buy, but I want to hear some options)

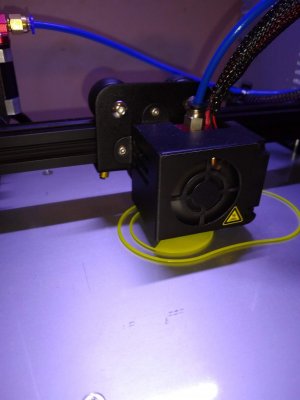

We run two of them, and will be adding 4 more soon. However,we will likely convert them all over to V6 hotend for better PETG performance.

Couldn't agree more. When that first layer goes down well....everything else from there is just perfect.

Agree with everyone else here - the Ender3 is a great choice for an under 500 3D printer. Its easy to setup and easy to upgrade.

We run two of them, and will be adding 4 more soon. However,we will likely convert them all over to V6 hotend for better PETG performance.

Better PETG performance? It gets better?

I love it on my stock hot end with a silicone sock.

- Joined

- Oct 3, 2015

- Messages

- 5,148

- Reaction score

- 8,760

Love my Ender 3. The only thing is the bed size, if you need to make larger objects then a CR-10S would be my choice...I had one and wish I still had it. I haven’t kept up but there is a CR-10S Pro which looks interesting.

I have a GeeeTech A30, which is similar to a CR10s. 2 Z screws, glass bed, Auto bed leveling, etc. However, it just seems way less rigid than an ender, due to the height. 16" screws just supposed by a stepper motor is.... not great. Vibrations galore when you get up there. I mainly use like 320x320x130- the bottom 5", rather than using the height.

Enders have been more reliable IME

- Joined

- Oct 3, 2015

- Messages

- 5,148

- Reaction score

- 8,760

We run two of them, and will be adding 4 more soon. However,we will likely convert them all over to V6 hotend for better PETG performance.

Better PETG performance from different hotend? It's already all metal, what difference are you going for? I thought going direct drive would be better than changing the hot-end.

This was another question I had @TheHarold thanks for asking it

I just like the V6 hotend over the MK10 that comes with it for printing PETG at high(ish) speeds. Don't get me wrong - the stock nozzle works well. I just prefer the V6 and all our other printers use theV6, so it easier to stock spare parts.Better PETG performance from different hotend? It's already all metal, what difference are you going for? I thought going direct drive would be better than changing the hot-end.

In fact, we use a slightly under gauged .4mm V6 clone nozzle when printing most of our PETG parts. They just come out cleaner with the print process we have developed.

On the stock nozzle though, at least one of the ender3s we have (the first one we got) does not have an all metal hotend - there's still PTFE tube inside, and have had to replace it twice now. of course we run that thing hot and for days at a time, so not surprising. I have not torn apart the second one yet, so not sure on that one.

I'm not sure - i plan to find out though. All our other printers seem to do better with PETG than the Endres - at least at speed. And they all use V6 clones. So I figured it would be worth a try. Printing out the pars nowBetter PETG performance? It gets better?

I love it on my stock hot end with a silicone sock.

I just like the V6 hotend over the MK10 that comes with it for printing PETG at high(ish) speeds. Don't get me wrong - the stock nozzle works well. I just prefer the V6 and all our other printers use theV6, so it easier to stock spare parts.

In fact, we use a slightly under gauged .4mm V6 clone nozzle when printing most of our PETG parts. They just come out cleaner with the print process we have developed.

On the stock nozzle though, at least one of the ender3s we have (the first one we got) does not have an all metal hotend - there's still PTFE tube inside, and have had to replace it twice now. of course we run that thing hot and for days at a time, so not surprising. I have not torn apart the second one yet, so not sure on that one.

Yea, my Ender 3 did not come with an all metal hot end as well....upgraded to a Microswiss...much better performance less clogs

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

I have found modelling your own designs to be easier than modifying other peoples designs. Check out Lars Christensen's tutorials on youtube for F360, they were invaluable to me when I started. I also think learning at least basic CAD is really a must do if you own a 3D printer. Your designs might not be the prettiest for a while but it really unlocks the potential of home 3D printing.I love the test kit trays I saw.. I would love to have a few other choices for some red sea and salifert.. Heck maybe even a couple other hanna ones. I just dont know the first thing about designing them.. Love my creality CR10s and need to get my monoprice mini going again..

There is a few frag racks on thingiverse but a kessil shroud will probably be hard to find. Modelling one yourself shouldn't be too hard. As I said above, Lars Christensen's tutorials on youtube should helpOrdered a Prusa MK3S witch should be here this week. I’m hoping to make a frag rack and and shroud for my Kessil H380 to contain the light in my Fuge section. Will start learning how to use Fusion 360 but if anyone has an STL file for a light shroud that Incould possibly modify, that would be great.

Different materials need the nozzle to be different distances away from the bed. If your PLA first layers are grainy tweak how far away from the bed the nozzle is. Likewise if PETG has a stringy first layer and isn't bonding then bed level is the first thing I would check. I also use glue stick on the bed as while I can usually print fine without it I find it really helps nail down that perfect first layer (it also helps to stop PETG from literally bonding to the glass and being impossible to remove).That first layer looks great, is it so smooth because you are using PETG? My PLA first layers always have some "grain" to them.

My PLA printing has been going well but I just started experimenting with PETG the other day and still need to get my settings dialed in, the first layer is stringy and not bonding to itself. What kind of settings changes did you need to make between PLA and PETG?

Between materials (aside from double checking bed level) you should tune your nozzle and bed temperatures as well as speed, and retraction. If I am still having issues I also tune the extruder steps per mm. It can take some tweaking but you should be able to get good first layers (and just prints in general) with any material, although quality varies and good quality filament (doesn't always mean expensive) will be easier to dial in.

First thing I do with any new roll of filament is a temperature tower. Then usually I will use that to pick the best nozzle temp and just get straight into printing whatever I wanted to print. But if I think that a material might need a bit more tuning I will do a further calibration print (lots of different ones on thingiverse) and then usually I also do a benchy to confirm that the settings are dialled in (but I don't really need to do that often anymore).

I usually print PLA at 190/60 and PETG at 230/70. I print everything on a glass bed with glue stick and a skirt that is 2-3 walls thick. I watch the skirt go down and if I need to I'll tweak the bed height while the skirt is printing and then walk away with confidence

- Joined

- Oct 3, 2015

- Messages

- 5,148

- Reaction score

- 8,760

I'm not sure - i plan to find out though. All our other printers seem to do better with PETG than the Endres - at least at speed. And they all use V6 clones. So I figured it would be worth a try. Printing out the pars now

What mount are you using- petsvang? Bullsseye? Don't need much cooling for PETG...

So this is what you like?

https://www.amazon.com/gp/product/B...4df-15aac5223b10&pf_rd_r=AB04PPE2S1N7R65WJR71

What mount are you using- petsvang? Bullsseye? Don't need much cooling for PETG...1

Starting with the Bullseye - have the fist part of the mount printed out and it came out pretty good. Did it in PLA Pro

So this is what you like?

https://www.amazon.com/gp/product/B...4df-15aac5223b10&pf_rd_r=AB04PPE2S1N7R65WJR71

Yea - basically. But I've narrowed it down a few different manufactures for the various parts as opposed to a full assembly. I buy the nozzles from one company, then the throats and blocks from another. As you can imagine, we keep a pretty good supply of spare parts on hand ;-)

Similar threads

- Replies

- 2

- Views

- 178

- Replies

- 2

- Views

- 138

- Replies

- 20

- Views

- 1,196