- Joined

- Dec 5, 2017

- Messages

- 2,888

- Reaction score

- 4,374

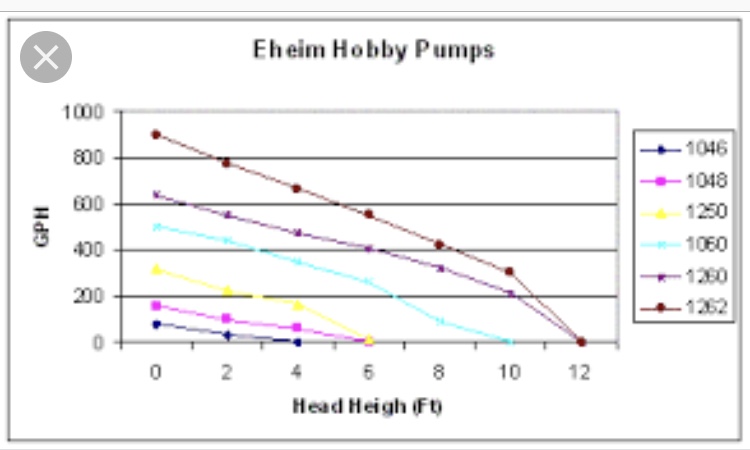

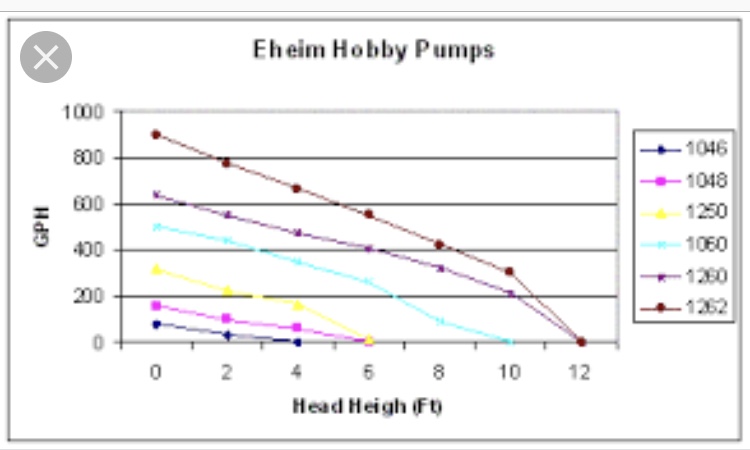

A head loss chart should look like this

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

A head loss chart should look like this

Is a DC pump worth it?

Make sure you leave enough room for the particular skimmer that you want to use. Check the footprint of the skimmer before you build the sump.

This is how I built my 40B sump. The end section was used as a frag tank, but could be used as a refugium as well. It was fed off of a manifold that had a dedicated pump.

I build sumps al the time as I'm an acrylic DIY freak, lol

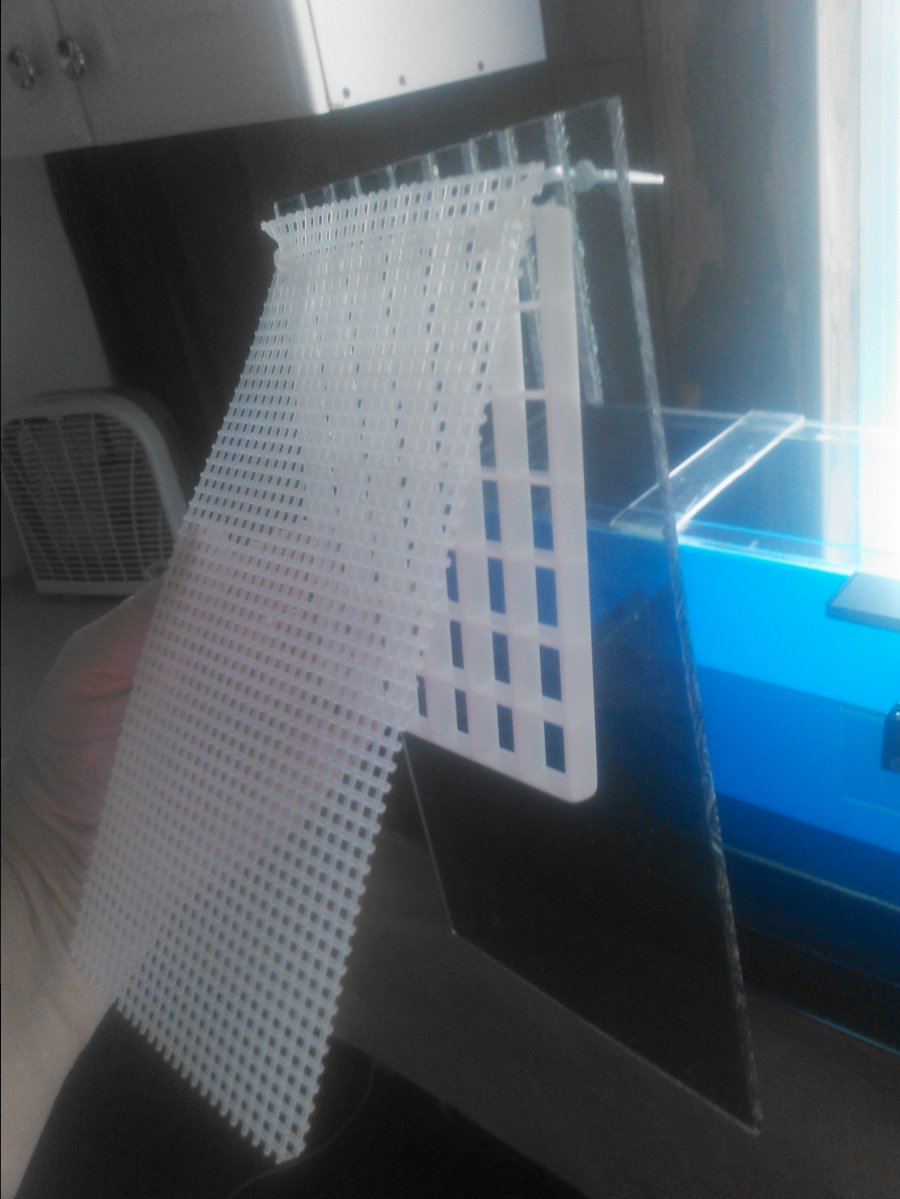

The sump looks great, but may be a maintenance nightmare. The baffles liik a bit skinny to keep clean and a biit overkill. As mentioned above not needed from refugium, I would make 1 baffle and lead from yhe top woth a piece of craft sewing plastic. it stops chaeto debree and bubbles to return pump.

here is a pic of one of my DIY turf scrubbers showing the plastic craft square sheet on the front of it you can cut to size. Hope this helps, You can order on amazon in 12 packs cheap under sewing craft supplies.

Acrylic doesn’t bond to glass. You might get it to stay but it will easily pop out. Also acrylic expands so you will have to leave a small gap between the sides or it could break the glass. If you want a solid water tight bond you have to use glass on glass or acrylic on acrylic.

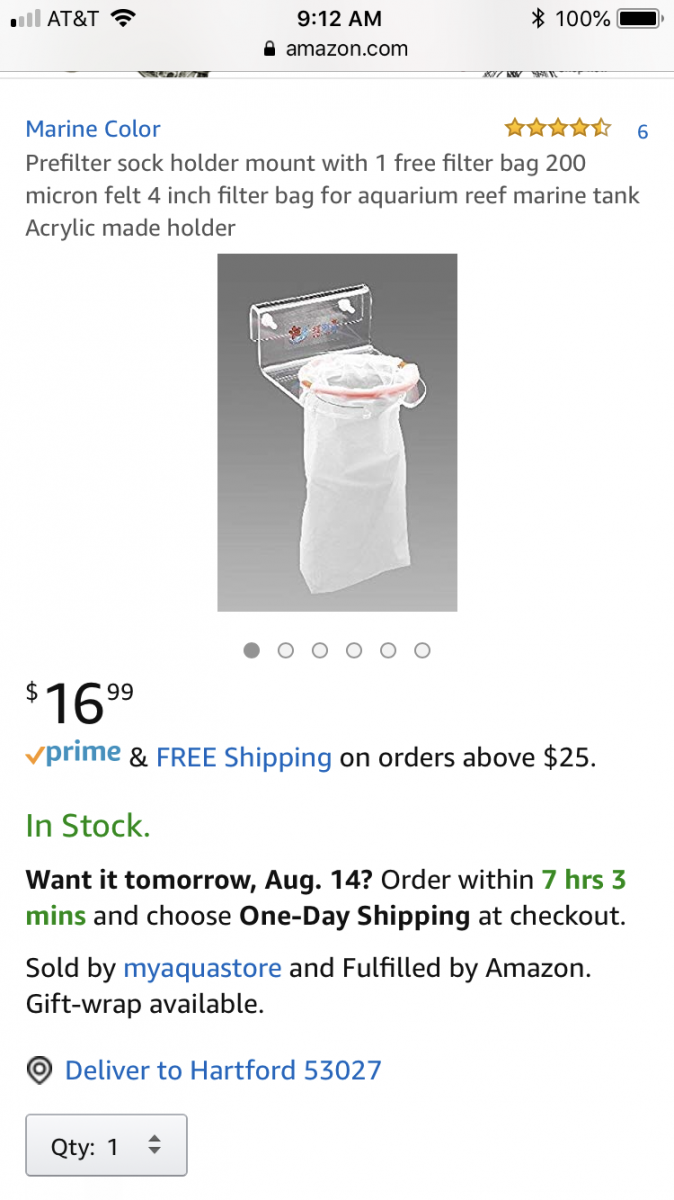

I’ve seen baffles put in like that just pop out. Not sure why you would have to drill baffles. There’s really no point in over complicating a design. For filter sock holders I would just buy something like this.

Acrylic can and will expand with heat- like almost every other solid material on the planet. But in the sizes and the function we are talking, I can't think this is anything more than a non-issue. It's going to be vaguely 70-85 degreesF where you are measuring and cutting the acrylic. That's also the operating temperature of your aquarium. (yes, I suppose expansion is possible while cutting with power tools due to friction - but that's getting pedantic. You size the part before gluing/solving to another part.)

In scientific terms, acrylic has a linear thermal expansion coefficient of under .000042. (Yes, you are right: that's 8-20 times more than some glass.) However, we are talking total expansion of under 1/100th of an inch per foot of material under normal room temperature conditions. Source 1; Source 2

As long as you are slightly undercutting the acrylic (which you should be doing in order to leave room for the silicone to create a barrier and to bond with all surfaces,) I have to expect you'll be fine. The silicone will easily compress enough to absorb the potential expansion amounts we are talking about for years of stable use.

Full disclosure - fabricating with acrylic and silicone is a bit of an art as well as a science. I personally have assisted individuals that I would consider masters of this art; I've learned a lot from them. I am not one of those artists. My own work is very shoddy and utilitarian. However, I get the concepts of the science half of it; I just lack the decades of experience making things look clean.

As far as drilling goes - sure - another winning feature of acrylic is it's inherent workability. You can drill/cut in strainer teeth, height adjustable baffles, etc. with much more ease than glass. And when you mess up - because you will - you can easily replace it.

You're on the right track. Let's see it made!

Acrylic can and will expand with heat- like almost every other solid material on the planet. But in the sizes and the function we are talking, I can't think this is anything more than a non-issue. It's going to be vaguely 70-85 degreesF where you are measuring and cutting the acrylic. That's also the operating temperature of your aquarium. (yes, I suppose expansion is possible while cutting with power tools due to friction - but that's getting pedantic. You size the part before gluing/solving to another part.)

In scientific terms, acrylic has a linear thermal expansion coefficient of under .000042. (Yes, you are right: that's 8-20 times more than some glass.) However, we are talking total expansion of under 1/100th of an inch per foot of material under normal room temperature conditions. Source 1; Source 2

As long as you are slightly undercutting the acrylic (which you should be doing in order to leave room for the silicone to create a barrier and to bond with all surfaces,) I have to expect you'll be fine. The silicone will easily compress enough to absorb the potential expansion amounts we are talking about for years of stable use.

Full disclosure - fabricating with acrylic and silicone is a bit of an art as well as a science. I personally have assisted individuals that I would consider masters of this art; I've learned a lot from them. I am not one of those artists. My own work is very shoddy and utilitarian. However, I get the concepts of the science half of it; I just lack the decades of experience making things look clean.

As far as drilling goes - sure - another winning feature of acrylic is it's inherent workability. You can drill/cut in strainer teeth, height adjustable baffles, etc. with much more ease than glass. And when you mess up - because you will - you can easily replace it.

You're on the right track. Let's see it made!

I’ve seen a few post from people who cut acrylic for baffles and broke their glass sump. I would not make the baffles a tight fit is all I’m saying.

I’ve read several post like these. There is supposed to be some type of silicone that will bond the two but I don’t what it is. Just be aware if a baffle pops out and you want to put it back you will be draining and drying the sump out. I’m not say it won’t work good enough to get away with for a while anyway. Personally I would rather not be messing around with my sump 5 years down the road because I bumped a baffle and it came out but that’s just me. Also drilling glass isn’t any harder then drilling acrylic. The only difference is you use water to cool the drill bit. I drilled my DT with no previous experience and had no problem at all.