Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5ft of questionable decisions....

- Build Thread

- Thread starter Knology

- Start date

- Tagged users None

- Joined

- Aug 12, 2018

- Messages

- 5,806

- Reaction score

- 8,226

Nice!

Lookin good !

I got a lot done over the weekend. The frame is now completely skinned and ready for covering. I did an enamel coat around all of the areas that may have moisture contact.

Next I need to design the hood, which I am hoping to make removable, and then design how to trim around the frame, tank, and doorway.

Next I need to design the hood, which I am hoping to make removable, and then design how to trim around the frame, tank, and doorway.

Last edited:

Well, I got a lot done over the weekend.

The tank is now on the stand. Most of the stand trim and design is now done. I have to to a lot of filling in the cracks, holes, and imperfections before paint. I also got the bulkheads in place and the elbows put in so I can run pipes in and down the center of behind the stand.

Worth noting, all of the trim around the top of the tank is PVC. I wanted to make sure that anything that actually may come into contact with water, continually, would never rot. The rest of the trim is primed pine. Going with MDF would have been cheaper, but sooner ro later I am sure it would have got wet.

Now the only thing is to design the doors for the hood access. Right now I am playing with an inset panel idea that is just held in place with magnets.

The tank is now on the stand. Most of the stand trim and design is now done. I have to to a lot of filling in the cracks, holes, and imperfections before paint. I also got the bulkheads in place and the elbows put in so I can run pipes in and down the center of behind the stand.

Worth noting, all of the trim around the top of the tank is PVC. I wanted to make sure that anything that actually may come into contact with water, continually, would never rot. The rest of the trim is primed pine. Going with MDF would have been cheaper, but sooner ro later I am sure it would have got wet.

Now the only thing is to design the doors for the hood access. Right now I am playing with an inset panel idea that is just held in place with magnets.

Looks incredible. Great job.

Well done

So, while we wait for the next boring step, sanding and finishing before paint, I figured it was time to start talking about the equipment and plans.

I have had a few tanks since 2007. I had a custom 90 and 2 custom 120's that never saw water as I had to move across the country a few times, due to life, and they never were completely finished. Well wait, one saw water and then I got laid off that same week. Aww. I had a 15g Biocube, then a custom 30 and then I actually did have a nice 30g rimless cube for a couple years and that was stepping in the right direction. It was mostly DIY and I liked how it turned out for a custom touch. That was about 3 years ago. I can honestly say though, because of life and chaos, I never had the time to educate myself enough for the tank to succeed. I had so little setup for automation and too many decisions were based on a tight budget and impatience.

Now that we own a home, we don't plan to move until the kids leave home, and we have the space to go all in and do it right, the above project is the scope it is. After hundreds of hours of research and years of stalking around the forums, I'm trying to do this tank the right way while considering all of the new advances in technology, ULM methods, Triton, roller mats, LED, DC pumps, etc etc. Reefing has changed a lot since I started back in 2007 and I have to actually give BRS a lot of props for their evolution and addition to my knowledge. The last few years of their video series has lead to a great deal of research and inspiration into what works vs trying method after method after method.

So here is my preliminary thoughts. Most of these are based on being naturally budget minded but buying the right solution for long term success. Some things will be put in first and other things will be left for when it's needed later. I am attempting to design the whole system for the future in mind. I want to leave space or design solutions to incorporate what comes later.

- The new Kessil A360x's for lighting. 3 of them should do the trick.

- I'm not set on one, but I am very closely watching all of the new roller mat options. This is a hands down a must(so far) in my design and I/we/everyone hates filter socks.

- 2 DC return pumps. These will be run from the basement and I want two for safety and load spread. I am still unsure what brand I'll get but I have kept my eyes on the Jeboa's for a while. There are too many DC pumps on the market right now that have astronomical pricing.

- I may consider an external pump but there are so many negatives I'd like to steer from. Noise, it being external and the drilling needed, and no redundancy. Still considering.

- I'm going to stick to a realistic turnover for the whole system through the sump. Probably 5-7X. Flow will be much higher of course.

- Flow - I am really interested in the Gyre pumps that have come out do to their cost against Vortech's and the ability to run 1 vs multiple powerheads. Let's face it, all things Ecotech are very expensive. The new Maxpect Gyre 300 warrants soem research.

- Water changes will be automated. I think I want to incorporate a slow pull and fill for each day. I have a lot of research on how to keep stable chemistry with this method.

- I already have a good amount of dry rock ready for when I aquascape. I strill have no real idea how that is going to coem out, but I'll grab another 40-60lbs and start putting the pieces together this spring.

- I am still on the fence about the Triton method vs BRS/WWC method and have a lot of research to continue.

- I will run a large sump with a refuguim.

I do think this is worth saying, I do not have any intention of having a SPS dominant tank. There is so many new methodologies and content that seems to be basing a lot of their processes on supporting huge SPS heavy tanks. The WWC tanks for instance have a huge emphasis on what it takes to produce such sustainability and growth with some of the most difficult coral. I am more attracted to a mix of movement, color, and fish. That, of course, can be more difficult to accomplish.

Well, back to filling in nail holes in wood and sanding. More to come. Of course.

I have had a few tanks since 2007. I had a custom 90 and 2 custom 120's that never saw water as I had to move across the country a few times, due to life, and they never were completely finished. Well wait, one saw water and then I got laid off that same week. Aww. I had a 15g Biocube, then a custom 30 and then I actually did have a nice 30g rimless cube for a couple years and that was stepping in the right direction. It was mostly DIY and I liked how it turned out for a custom touch. That was about 3 years ago. I can honestly say though, because of life and chaos, I never had the time to educate myself enough for the tank to succeed. I had so little setup for automation and too many decisions were based on a tight budget and impatience.

Now that we own a home, we don't plan to move until the kids leave home, and we have the space to go all in and do it right, the above project is the scope it is. After hundreds of hours of research and years of stalking around the forums, I'm trying to do this tank the right way while considering all of the new advances in technology, ULM methods, Triton, roller mats, LED, DC pumps, etc etc. Reefing has changed a lot since I started back in 2007 and I have to actually give BRS a lot of props for their evolution and addition to my knowledge. The last few years of their video series has lead to a great deal of research and inspiration into what works vs trying method after method after method.

So here is my preliminary thoughts. Most of these are based on being naturally budget minded but buying the right solution for long term success. Some things will be put in first and other things will be left for when it's needed later. I am attempting to design the whole system for the future in mind. I want to leave space or design solutions to incorporate what comes later.

- The new Kessil A360x's for lighting. 3 of them should do the trick.

- I'm not set on one, but I am very closely watching all of the new roller mat options. This is a hands down a must(so far) in my design and I/we/everyone hates filter socks.

- 2 DC return pumps. These will be run from the basement and I want two for safety and load spread. I am still unsure what brand I'll get but I have kept my eyes on the Jeboa's for a while. There are too many DC pumps on the market right now that have astronomical pricing.

- I may consider an external pump but there are so many negatives I'd like to steer from. Noise, it being external and the drilling needed, and no redundancy. Still considering.

- I'm going to stick to a realistic turnover for the whole system through the sump. Probably 5-7X. Flow will be much higher of course.

- Flow - I am really interested in the Gyre pumps that have come out do to their cost against Vortech's and the ability to run 1 vs multiple powerheads. Let's face it, all things Ecotech are very expensive. The new Maxpect Gyre 300 warrants soem research.

- Water changes will be automated. I think I want to incorporate a slow pull and fill for each day. I have a lot of research on how to keep stable chemistry with this method.

- I already have a good amount of dry rock ready for when I aquascape. I strill have no real idea how that is going to coem out, but I'll grab another 40-60lbs and start putting the pieces together this spring.

- I am still on the fence about the Triton method vs BRS/WWC method and have a lot of research to continue.

- I will run a large sump with a refuguim.

I do think this is worth saying, I do not have any intention of having a SPS dominant tank. There is so many new methodologies and content that seems to be basing a lot of their processes on supporting huge SPS heavy tanks. The WWC tanks for instance have a huge emphasis on what it takes to produce such sustainability and growth with some of the most difficult coral. I am more attracted to a mix of movement, color, and fish. That, of course, can be more difficult to accomplish.

Well, back to filling in nail holes in wood and sanding. More to come. Of course.

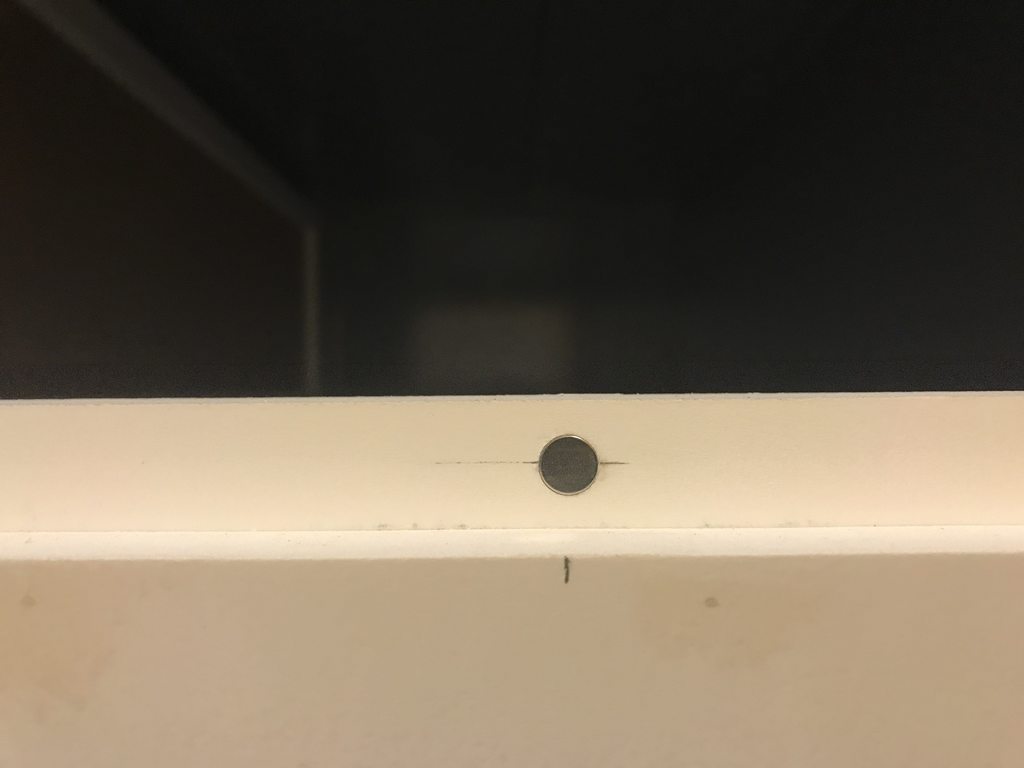

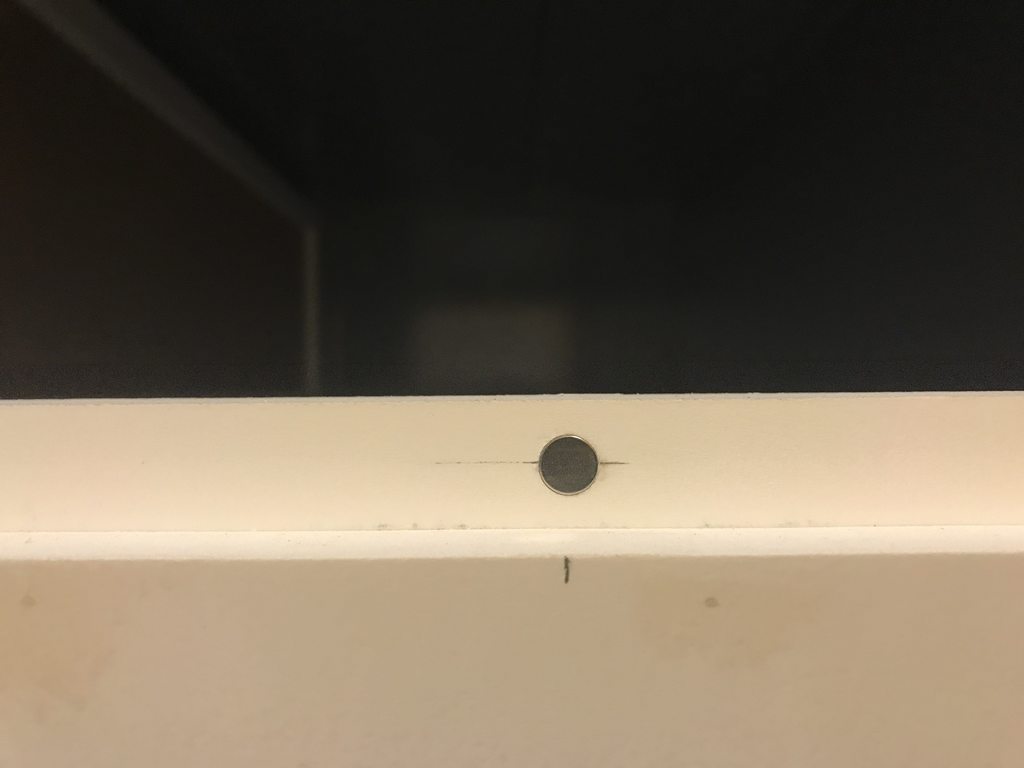

OK, the hood access panels are going well so far.

I am using a hardboard for these due to rigidity and thickness. They are only 1/8" thick and about as hard as an acrylic panel. I wanted to just make something that can VERY EASILY be popped in place/removed without the need for hinges, hardware, or be complex. They need to block out all light from the edges but also be soemthing that can be popped out a million times without wear.

The front panel will get trim slats as well.

I countersunk some magnets into the surface of the panel recess. I also have some magnetic tape I'll adhere to the door itself around the entire edge and then enamel over. This should give me an entire edge surface to stick to the tank and bloc out any light bleed. If the magnets installed in the stand isn't enough, I'll just add some more countersunk magnets.

I am using a hardboard for these due to rigidity and thickness. They are only 1/8" thick and about as hard as an acrylic panel. I wanted to just make something that can VERY EASILY be popped in place/removed without the need for hinges, hardware, or be complex. They need to block out all light from the edges but also be soemthing that can be popped out a million times without wear.

The front panel will get trim slats as well.

I countersunk some magnets into the surface of the panel recess. I also have some magnetic tape I'll adhere to the door itself around the entire edge and then enamel over. This should give me an entire edge surface to stick to the tank and bloc out any light bleed. If the magnets installed in the stand isn't enough, I'll just add some more countersunk magnets.

I got half of the surround painted. This is a Glidden exterior semi-gloss and it will be about three coats when I am done. I am going to paint the door the same color but in the long run there will be a better door going to the basement with glass panels. That will come down the road when I'm no longer lugging up equipment from the basement and demo. No reason to ruin a new door until other projects are done.

I am starting to realize that this project is coming out better than expected. I like the color as well though is makes the other colors in the house scream at me how badly they need changed. We purchased this house a year ago and the prior owners heavily neglected cosmetic upkeep and their color choices are vastly different then our own.

What I'm saying is....fish tank comes first. Make house better comes second.

I twisted my ankle really bad on Sunday, just normal household chores shenanigans, and had to cut the weekend short. For now I'm just stalking around the internet looking for design ideas for the fish room. Not much I can do until I can rely on my foot again.

I am starting to realize that this project is coming out better than expected. I like the color as well though is makes the other colors in the house scream at me how badly they need changed. We purchased this house a year ago and the prior owners heavily neglected cosmetic upkeep and their color choices are vastly different then our own.

What I'm saying is....fish tank comes first. Make house better comes second.

I twisted my ankle really bad on Sunday, just normal household chores shenanigans, and had to cut the weekend short. For now I'm just stalking around the internet looking for design ideas for the fish room. Not much I can do until I can rely on my foot again.

Last edited:

- Joined

- Jan 2, 2019

- Messages

- 432

- Reaction score

- 563

This is going to be a great build. But really, I'm just in awe - it took only 48 hours to convince your wife to purchase that tank? You got ***** skills!

Edit - that wasn't a dirty word that got bleeped out - just another word for hades, with an "a" tacked onto the end. Go figure...

Edit - that wasn't a dirty word that got bleeped out - just another word for hades, with an "a" tacked onto the end. Go figure...

Looking good @Knology ! Hope that ankle feels better.

Well, I realized yesterday we are getting pretty close to the tank, just the big glass box in a wall, being done. What dawned on me is that we are still from here to the moon on getting water into the thing though. I also kind of became a bit concerned about how long it takes from receiving a custom tank to the day you actually see if there is anything wrong with it. I won't know if there are any fabrication leaks until we are 95% finished. It is what is it, I'm just thinking out loud.

- I still need to plumb some PVC from the return lines (1") and the shadow overflow (1") down through the floor into the basement. They will remained roughed in until I figure out where they will ultimately route to in the basement. More on that below.

- Of course, I still need to paint the front side of the surround. I'm thinking a solid three coats in total all the way around.

- I setup the smaller hood access door with magnets and epoxied them into the panel. I've got the inside panel coated with a good glossy enamel and now I just need to paint the outside the exterior color of the surround and see how it looks. I may not like how non-precise the panel fits, so I may redo it in the long run. One of the sides has a 1/8" gap I may just try to overlook aesthetically. My only real priority is making sure there is no light bleed around the edges of the cover when they LEDs inside are on.

- I also need to finish up the access panel that is in the left side closet so we can turn it back into a closet. The closet side access, no pictures yet, will give me access the under the tank, all the wiring for the lights and power heads, and access to the left side glass panel to place a power head. It'll also be where their respective controllers will be placed.

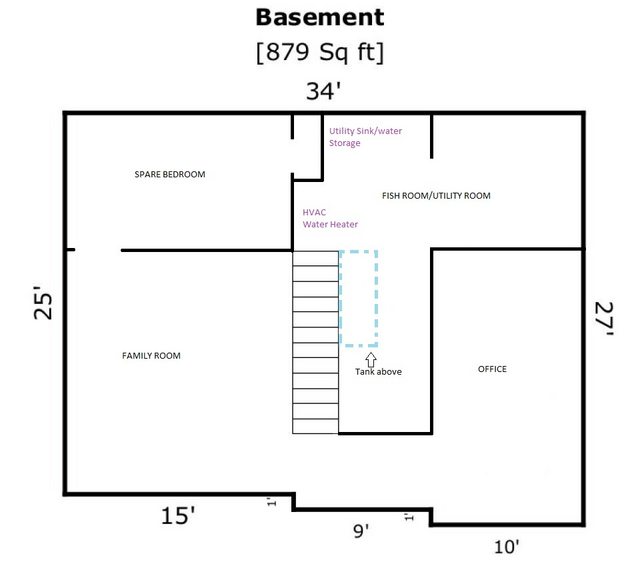

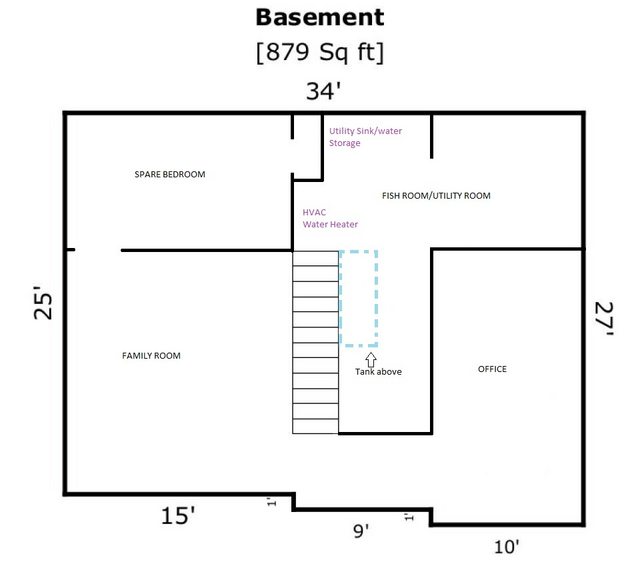

Anyway, here is some shots of the basement. After waling around there last night, I realized I also need a larger space. Maybe not all of it will be fish room (or so I tell my wife) but the space I had laid out was only 5.5" wide and maybe 20ft long. Only half of that could be used for fish tank space and some of it would be too close to the primary electrical panel and the entire HVAC system.

So, here is the drawing of what the new layout will be, roughly, and still pull off an office, spare bedroom, and family room.

Here are some pictures of what the basement looks like as of now. Yeah, a lot of work to do.

- I still need to plumb some PVC from the return lines (1") and the shadow overflow (1") down through the floor into the basement. They will remained roughed in until I figure out where they will ultimately route to in the basement. More on that below.

- Of course, I still need to paint the front side of the surround. I'm thinking a solid three coats in total all the way around.

- I setup the smaller hood access door with magnets and epoxied them into the panel. I've got the inside panel coated with a good glossy enamel and now I just need to paint the outside the exterior color of the surround and see how it looks. I may not like how non-precise the panel fits, so I may redo it in the long run. One of the sides has a 1/8" gap I may just try to overlook aesthetically. My only real priority is making sure there is no light bleed around the edges of the cover when they LEDs inside are on.

- I also need to finish up the access panel that is in the left side closet so we can turn it back into a closet. The closet side access, no pictures yet, will give me access the under the tank, all the wiring for the lights and power heads, and access to the left side glass panel to place a power head. It'll also be where their respective controllers will be placed.

Anyway, here is some shots of the basement. After waling around there last night, I realized I also need a larger space. Maybe not all of it will be fish room (or so I tell my wife) but the space I had laid out was only 5.5" wide and maybe 20ft long. Only half of that could be used for fish tank space and some of it would be too close to the primary electrical panel and the entire HVAC system.

So, here is the drawing of what the new layout will be, roughly, and still pull off an office, spare bedroom, and family room.

Here are some pictures of what the basement looks like as of now. Yeah, a lot of work to do.

- Joined

- Jul 13, 2016

- Messages

- 5,348

- Reaction score

- 6,710

If your trying to get 7x flow thru your sump

You will need to up the plumbing to 1 1-2 on the overflow and 1 1/4 on the pump one and one will be around 3x flow

You will need to up the plumbing to 1 1-2 on the overflow and 1 1/4 on the pump one and one will be around 3x flow

Yeah, the math gets tight at 7x. I've already got the Shadow overflow fitted with 1" reducers.

5x turnover will do fine.

5x turnover will do fine.

Last edited:

I got the trim finished around the adjoining frame. I have also got the first coat done on the front of the tank but the rest will be done this weekend.

So, now that the holidays have died down, and my HOA has got off my back, we can get back to the tank.

Well, the is the wall I was going to put the tank on. It actually turned out so good(pre-paint) that I decided it was a shame to cover it all with a tank. The dining room was going to re purposed into the tank, 2 sitting chairs, a bookshelf, and maybe a small table between the chairs in the bay window. A quite area to enjoy the tank and talk.

The issue was that is all that would fit in there. 2 chairs and a tank. I'd rather turn it into a smaller living room or just go back to a dining room.

So.... we are back to this

We are back to it being built into the kitchen spare wall. The trick with this spot is that it spans over 5 floor joists and the fish room is directly below the tank in the basement. THat was the final selling point.

The other trick is that this wall is 63" wide and the tank is 60". This way the tank will visually feel larger than it is as it will take up the entire wall. I'm going to leave the walls open to the left side and below that way I always have access to cable routing and piping. Everything above the tank will be skinned with PVC sheet and easily cleaned. My plan it to get the tank off the stand the weekend and onto the new frame. I have some vinyl coming in to cover the left side panel where it will be hidden behind the wall.

It's time to start thinking about building that fish room downstairs...

Good call, the party always ends up in the kitchen

I finally had the moment this weekend to stand back and look at this thing. After a million ADHD back and forth, I can look at this wall and see the vision I had in front of me almost complete.

Here is the side access panel painted and installed. The magnets have a great hold and I am happy how it turned out.

Next is getting the front access panels started and finish up the return line plumbing and overflow through the floor.

Here is the side access panel painted and installed. The magnets have a great hold and I am happy how it turned out.

Next is getting the front access panels started and finish up the return line plumbing and overflow through the floor.

You are for real!

Looks fantastic

Looks fantastic

Similar threads

- Replies

- 4

- Views

- 94