- Joined

- Jul 27, 2016

- Messages

- 1,149

- Reaction score

- 1,509

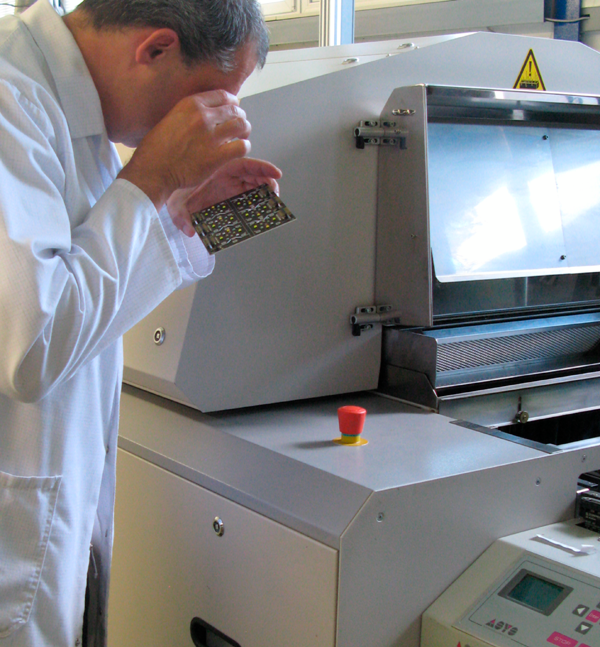

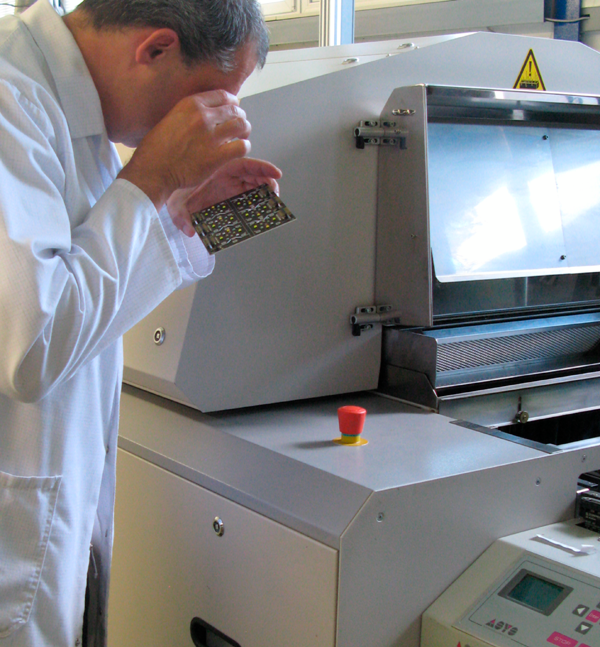

With the recent launch of the new Mitras LX 7x04 LED, we felt it would be a good opportunity to give you a close-up look at how we build and prepare our products.

In this video we show how the Mitras LX LED boards are manufactured in our production facility in Germany.

Did you know?

GHL has been manufacturing and developing its products for 2 decades!

From the beginning we've held true to our core values in believing that the aquarium industry deserves nothing less than the best. That's why to this day, we continue to oversee and control all major production processes to ensure your GHL product works safely and reliably for years to come.

Our inspection process

Each and every finished component undergoes rigorous testing and quality checks. We test our own boards and do our own QC checks. Even down to the inspection of each LED diode, we check it all.

We do it because...

We want to make sure that each and every product that leaves GHL HQ is tried and tested to perform reliably. While our competition may outsource these tasks, we do it all ourselves. That way, we can improve existing products and innovate new ideas and bring them to life without waiting on others to deliver.

Want to learn more about GHL?

Click here to learn more about our philosophy on quality assurance and the products we offer.

In this video we show how the Mitras LX LED boards are manufactured in our production facility in Germany.

Did you know?

GHL has been manufacturing and developing its products for 2 decades!

From the beginning we've held true to our core values in believing that the aquarium industry deserves nothing less than the best. That's why to this day, we continue to oversee and control all major production processes to ensure your GHL product works safely and reliably for years to come.

Our inspection process

Each and every finished component undergoes rigorous testing and quality checks. We test our own boards and do our own QC checks. Even down to the inspection of each LED diode, we check it all.

We do it because...

We want to make sure that each and every product that leaves GHL HQ is tried and tested to perform reliably. While our competition may outsource these tasks, we do it all ourselves. That way, we can improve existing products and innovate new ideas and bring them to life without waiting on others to deliver.

Want to learn more about GHL?

Click here to learn more about our philosophy on quality assurance and the products we offer.

Last edited: