I have some acrylic I need to bond a few pieces together to increase the height of one of my baffles.

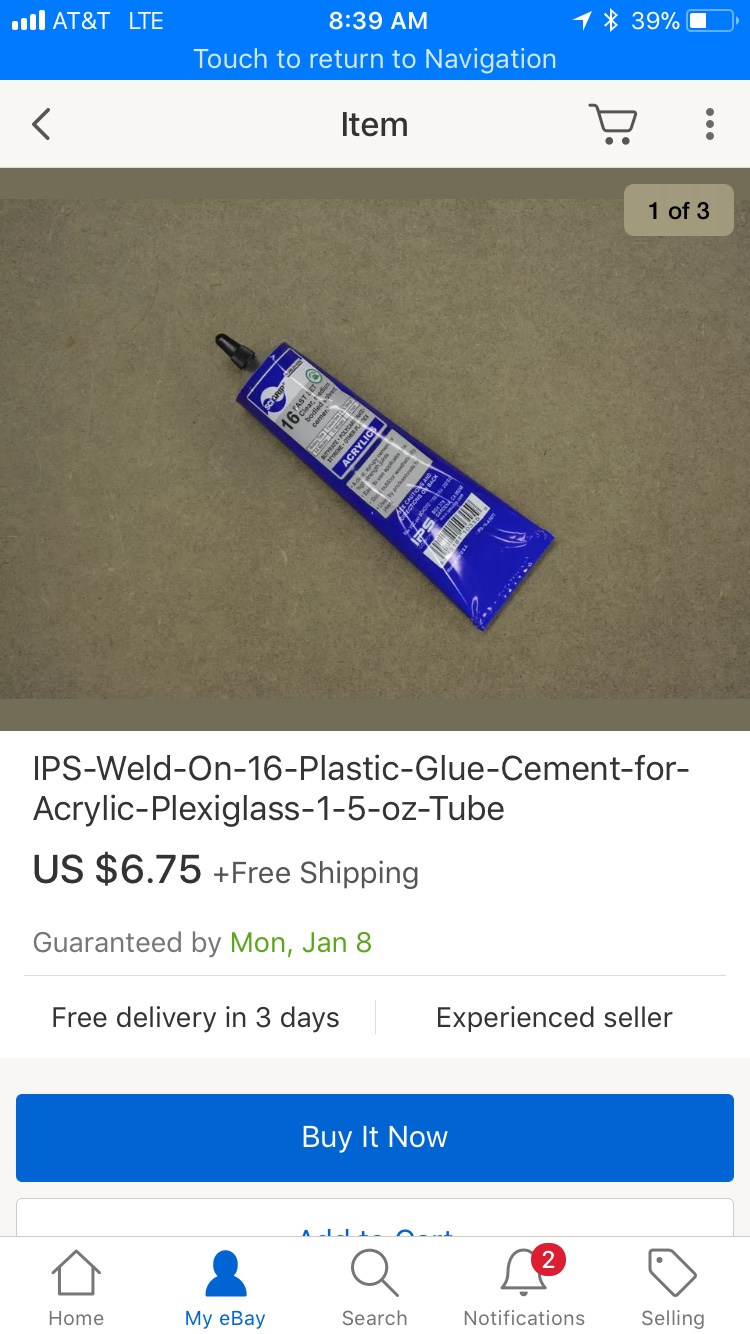

What do I use to glue them together, and does home depot carry the glue/solvnet?

Anyone have a link maybe?

Thank you!

What do I use to glue them together, and does home depot carry the glue/solvnet?

Anyone have a link maybe?

Thank you!