- Joined

- Aug 30, 2019

- Messages

- 250

- Reaction score

- 367

Hello everyone

As part of a new build (https://www.reef2reef.com/threads/15g-office-nano-tank-natural-sea-water.820995/) I have been having fun with a few DIY projects.

As they may be useful for others, I will try to make a few write ups in the DIY section.

You can check the build thread if you want to check the other DIY projects in the meantime (still finishing some).

Todays topic: DIY acrylic screen top

The inspiration for the screen cover came from the beautiful acrylic tops you can buy online.

While I did not expect to come up with the same results as the ones you can buy, I must say I’m pretty happy with the outcome.

I started by cutting a 3mm acrylic sheet to the dimensions of the tank (display area only, waterbox peninsula mini 15).

After that I 3d printed a guide that I glued to the acrylic using double sided tape.

The guide served two purposes:

Guide the router bit to cut the inside of the acrylic sheet

And allow me to drill holes in specific locations

Once that was done, I sanded the edges (some imperfections, as the guide is made of 4 individual parts and wasn’t fully secured).

I considered and tried many ways to attach the screen mesh to the acrylic. I tried different glues, but didn’t like the result of any of them.

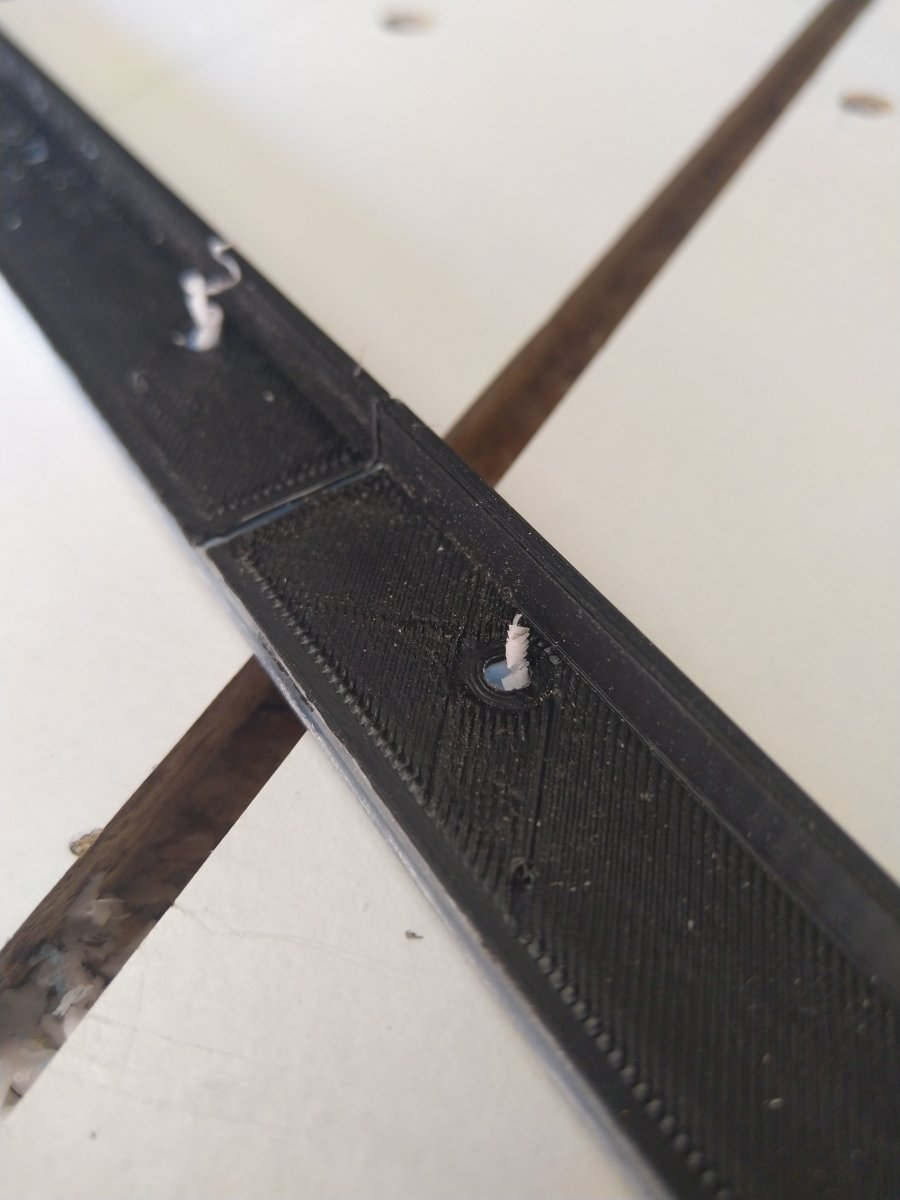

So instead, I 3d printed 4 pieces that fit on the bottom of the acrylic, which have small pins that fit on the drilled holes. That way the pins secure the net and the parts together.

The parts should cover the entire side, however due to printer issues, only the corners have been finalized.

The 3d printed parts also serve as a stopper on the inside of the glass, preventing the top from sliding over.

The tension of the net holds everything together, so I don’t need to glue it, making replacing the net very easy. Also, if you like to colour match the parts of the tanks you can always replace with different colours.

I will eventually print the parts to fit the entire length of the screen top.

If you don’t have access to a 3d printer, two sheets of acrylic (one that fits over the side of the tank and one that fits on the inside of the tank) should also work well. Then is just a question of clamping them together and drill the holes and use some plastic pins or nylon screws.

Interestingly I can barely see the black parts when looking at the tank…

All and all, pretty happy with the results

Hope it serves as inspiration for someone else.

Cheers

As part of a new build (https://www.reef2reef.com/threads/15g-office-nano-tank-natural-sea-water.820995/) I have been having fun with a few DIY projects.

As they may be useful for others, I will try to make a few write ups in the DIY section.

You can check the build thread if you want to check the other DIY projects in the meantime (still finishing some).

Todays topic: DIY acrylic screen top

The inspiration for the screen cover came from the beautiful acrylic tops you can buy online.

While I did not expect to come up with the same results as the ones you can buy, I must say I’m pretty happy with the outcome.

I started by cutting a 3mm acrylic sheet to the dimensions of the tank (display area only, waterbox peninsula mini 15).

After that I 3d printed a guide that I glued to the acrylic using double sided tape.

The guide served two purposes:

Guide the router bit to cut the inside of the acrylic sheet

And allow me to drill holes in specific locations

Once that was done, I sanded the edges (some imperfections, as the guide is made of 4 individual parts and wasn’t fully secured).

I considered and tried many ways to attach the screen mesh to the acrylic. I tried different glues, but didn’t like the result of any of them.

So instead, I 3d printed 4 pieces that fit on the bottom of the acrylic, which have small pins that fit on the drilled holes. That way the pins secure the net and the parts together.

The parts should cover the entire side, however due to printer issues, only the corners have been finalized.

The 3d printed parts also serve as a stopper on the inside of the glass, preventing the top from sliding over.

The tension of the net holds everything together, so I don’t need to glue it, making replacing the net very easy. Also, if you like to colour match the parts of the tanks you can always replace with different colours.

I will eventually print the parts to fit the entire length of the screen top.

If you don’t have access to a 3d printer, two sheets of acrylic (one that fits over the side of the tank and one that fits on the inside of the tank) should also work well. Then is just a question of clamping them together and drill the holes and use some plastic pins or nylon screws.

Interestingly I can barely see the black parts when looking at the tank…

All and all, pretty happy with the results

Hope it serves as inspiration for someone else.

Cheers