- Joined

- Mar 30, 2017

- Messages

- 470

- Reaction score

- 183

Some people religiously change once it hits 1, but some others don't until almost 5.

Lets hear what you prefer to do and why?

Lets hear what you prefer to do and why?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Some people religiously change once it hits 1, but some others don't until almost 5.

Lets hear what you prefer to do and why?

So there’s an argument both ways. The biggest issue with any TDS reading other than 0 is that what ever is in the water given you a reading is completely unknown. It can be 1ppm of Cal, Mag, Alk or any other beneficial element in which case it will not hurt your water.

The counter argument is that it can be 1ppm or more or something bad like heavy metals, arsenic, phosphate or what have you.

Realistically at those small levels plus the dilution factor once you figure in how small your water changes truly are is that it will most probably not have any negative effect on your system.

There are some salts that say use water of 10ppm or less with 0 being preferred.

Then comes me, my argument is that 0ppm on a TDS meter isn’t truly always 0PPM and let me tell you why.

1st, how long has it been since you last properly calibrated either your in-line meter or your hand held meter? If not Calibrated regularly then I guarantee you that your readings are incorrect.

2nd, there are elements within the water that are insulators. Silica being one of them. So what does that mean? It means that you can have 10ppm, 20ppm or evening more of Silica in your water but because it is an insulator (meaning it does not give off an electrical charge) your TDS meter will never read it or pick it up.

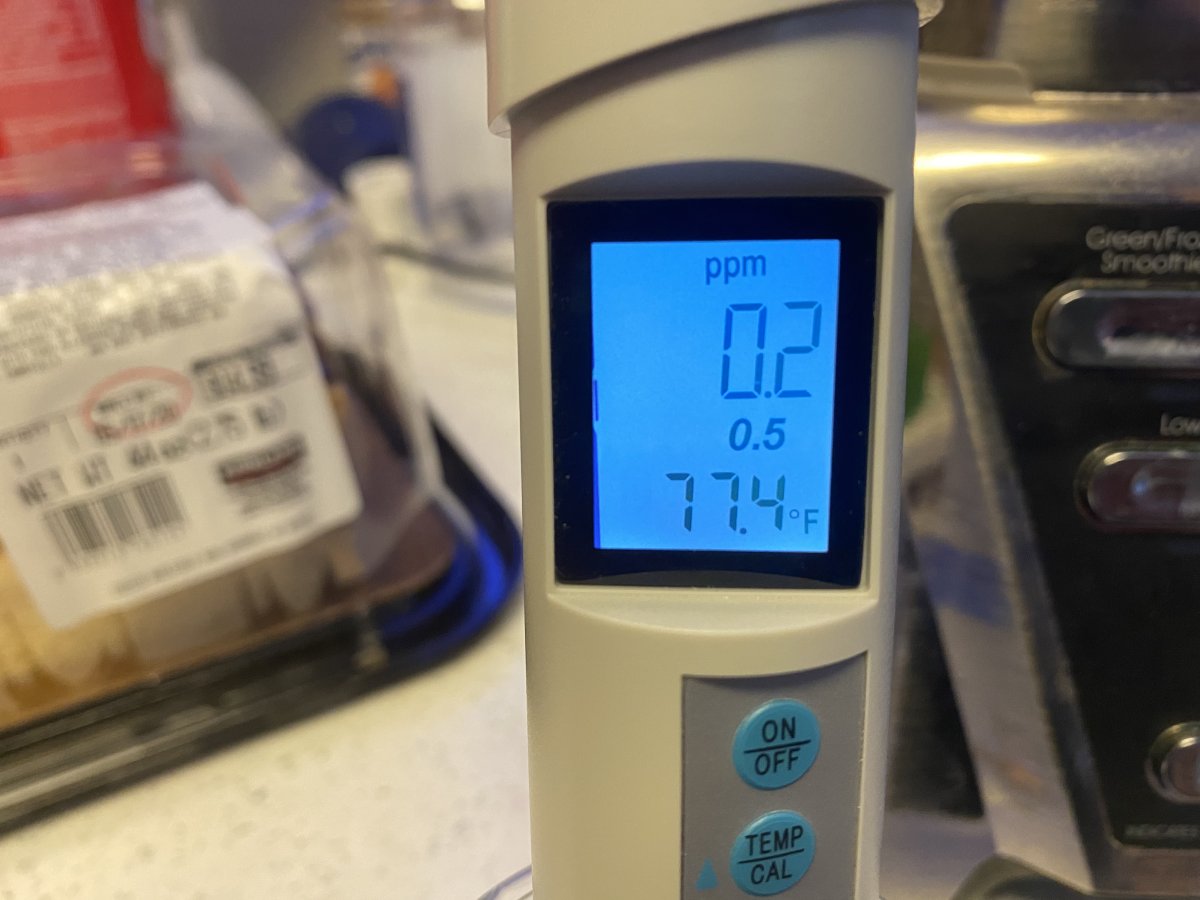

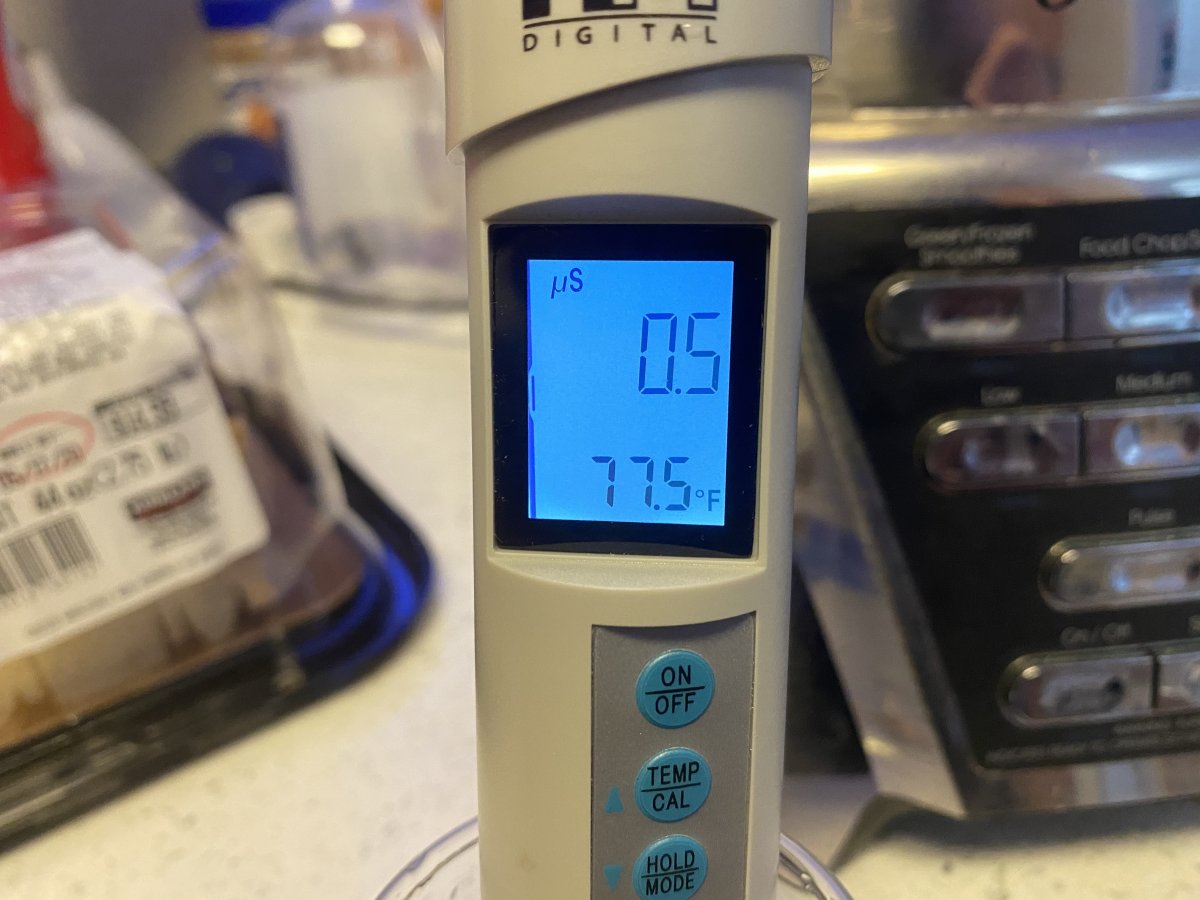

3rd, PPM is a rather small scale. Meaning that anything under 1.0 ppm will read as 0. For instance, EC will read in Microsiemens. 1ppm is equal to 1.56 microsiemens. Also there’s the limitations of your meter. If your meter only reads to 0 then you could have .9ppm level of TDS in your water but your standard in-line and handheld meter will still read 0ppm.

Now the question becomes well how do I truly know what my readings are?

First off Calibrate your meters with a known NaCL Solution.

I use HM Digitals 342ppm standard.

Next get yourself a true EC Meter like the HM Digital Com 100 which will give your readings in ppm format all the way down to 0.00ppm and even better yet reads in microsiemens also which is a greater range than PPM.

Lastly, ICP test your RODI water. That way you can test for elements that are not conductive to be sure and or to adjust the Type of DI you need.

Personally I Run three DI resins. This way every step polishes the last. So I am okay with my first Resin giving me a reading over 0. Because my second and third clean off my first. Once my second reason reads 1 I throw out the first, move the second and third resin up a slot and add a new one into slot three.

lastly here’s two pictures of what my calibrated in-line meter read as 0ppm and my calibrated Com-100 then read as under 1 but over 0.00.

Reading in PPM

Reading in Microsiemens

I wait till the TDS meter goes from 0 to 1. Back when I ran color changing resin, I stopped paying attention to the color change as it’d still produce 0 tds long after the color change. Because of that, I stopped using color changing resin and rely solely on my meter readings.