- Joined

- Oct 21, 2016

- Messages

- 242

- Reaction score

- 77

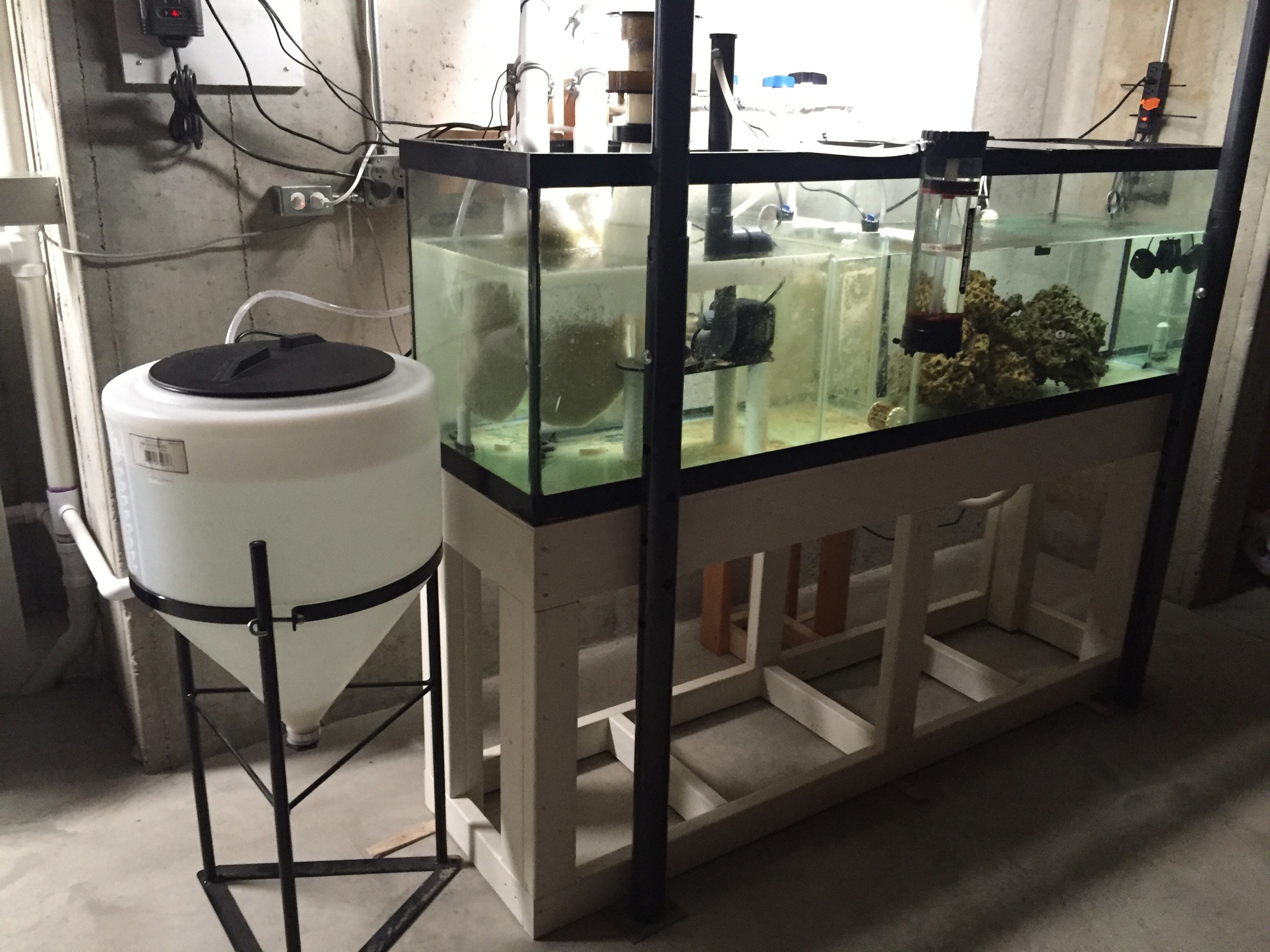

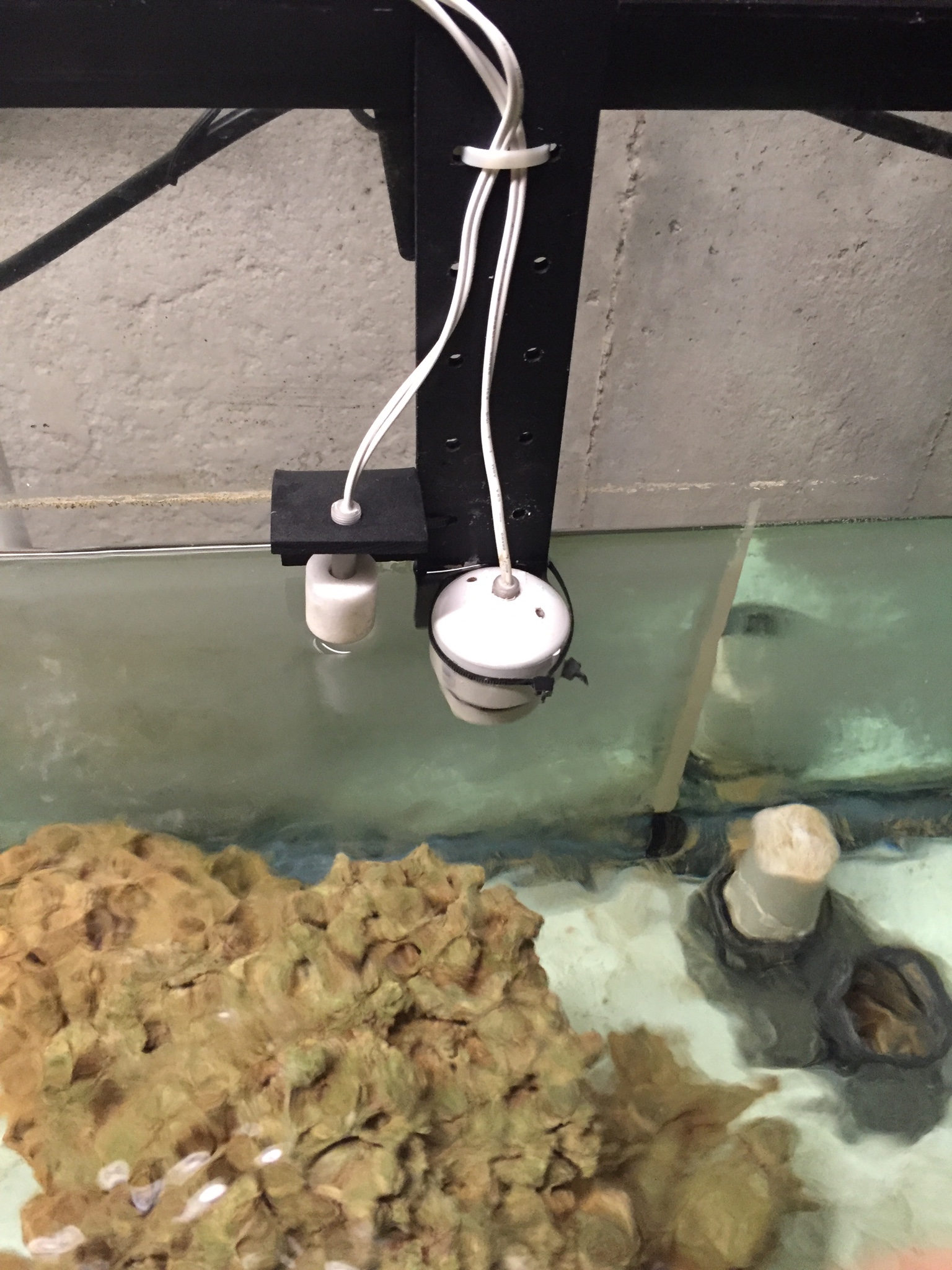

I recently plumbed a 100 gallon rubbermaid stock tank into my dt. The stock tank is in my basement which is slowly becoming a fush room. My issue is I went from a 15 gallon sump to about 65-70 in the rubbermaid. I have a hydor ato which was excellent for the 15 gallon, and I plan on using it for a frag qt. Unfortunately I didn't put baffles in the rubbermaid. The surface area is too large for the hydor and my aqua lifter, the pump stops after 5 minutes. Anyway I was thinking about either using gravity with a float valve or setting up float switches with my apex. I really like the idea of the gravity fed float valve and I have all the parts has anyone used this method?