- Joined

- May 21, 2008

- Messages

- 99

- Reaction score

- 20

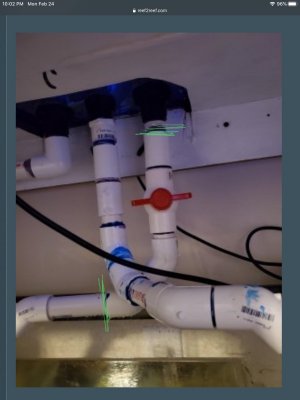

It was installed upside down, so i'm turning it counter clockwise. I'm turning it in the direction of the O indicator on the handle, ( there's an O and an S)You are trying to turn the handle clockwise to open?