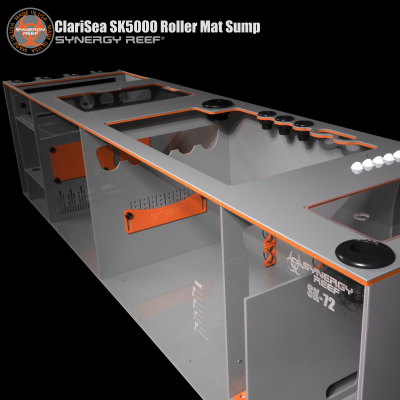

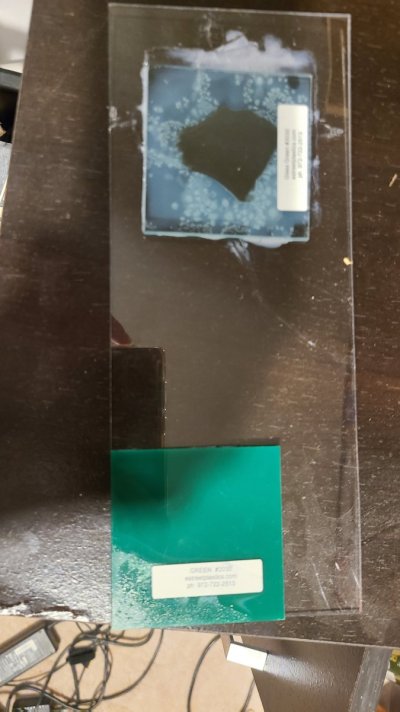

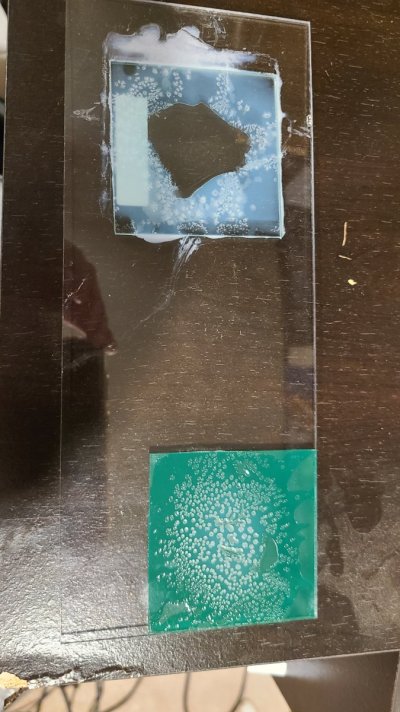

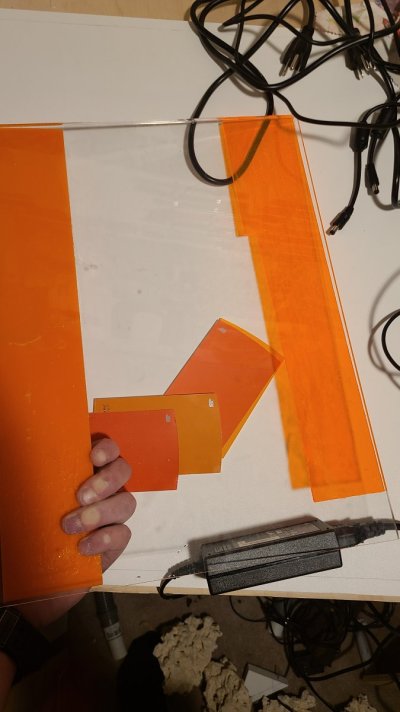

I've seen in some sumps like the octo reef where acrylic is bonded to the front of the sump to outline the chambers or when the top brace appears to be 2 different color sheets bonded together. How is this done? I've tried bonding scrap pieces to clear acrylic with Weldon, only to leave a mess of air bubbles. has anyone ever done this, or is there a particular method?