Thank You for the important pointThe GE silicone posted above bonds to glass and acrylic... I've done quite a few sumps with it and have yet to have a baffle leak, let alone fail. You do need to leave room for the acrylic to expand so it does not crack the glass though.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can Glass and Acrylic join

- Thread starter Sherman

- Start date

- Tagged users None

I second this as im in the same boat with doing the same exact thing, no issues so far.40 gallon breeder convert into sump using a Fiji sump kit and Ge number 1 silicon. Gotta get 100 coverage with the seams and like a pervious reply stated let dry for 4 days or more. Mine waited a couple weeks while i drilled my 110 gallon and got my stand done. The sump buffles felt pretty solid and has been up and running for a couple of months now with no issues.

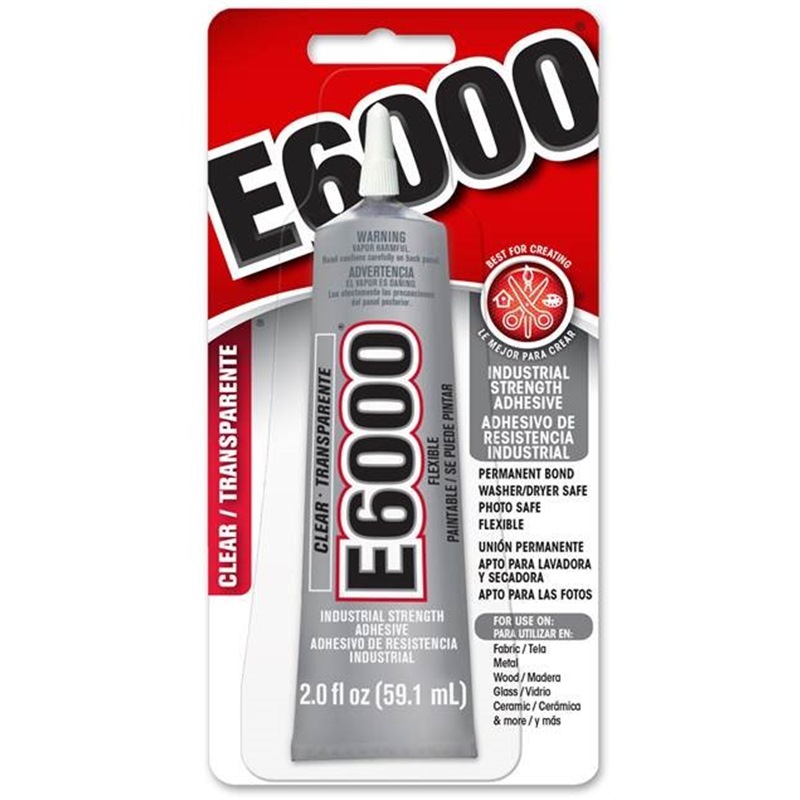

I've used the e6000 in the past with success. Let it cure. I've been told it wasn't reef safe but eh. Once cured it doesn't matter imo.

D

D

I've installed acrylic/plexiglass baffles into many glass aquariums.

I always use ASI aquarium sealant. It's 100% silicone with no additives. $11 for a 10oz tube. Amazon.

I always use minimum 3/16" acrylic and prefer 1/4" thickness.

I'm pretty particular about how I assemble things. My method has always been to cut the baffles 1/8" narrow (1/16" each side) , to allow for expansion and to allow for silicone to fit between the baffles and the glass. I notch the bottom corners at an angle to allow the baffles to clear the existing silicone in the tank. Then mask off the 3 sides that will have silicone attached, leaving 1/2" where the silicone will be applied. Grab a dremel/rotary tool and a 1/2" sanding drum. Run the dremel on LOW speed and scuff all 3 edges (both sides... front and back) where the silicone will touch the baffle. This gives the silicone some ridges and roughness to grab onto and adhere too. Remove masking tape.

Clean with soap and water to remove sanding dust AND any residual oil or film from the manufacturing process. Dry thoroughly with paper towels, then use a hair dryer to be sure it's completely dry. I blast it with the hairdryer until its warm all around the edges where the silicone will be applied. It's dry now. Let it cool to room temperature.

I caulk both sides of each panel. Use your favorite tool or finger to squish the silicone in tightly and form a radius. I prefer a cheap plastic spoon.

Clean up with isopropyl alcohol (91%) and paper towels. Let it cure for at least 2 or 3 days.

I always use ASI aquarium sealant. It's 100% silicone with no additives. $11 for a 10oz tube. Amazon.

I always use minimum 3/16" acrylic and prefer 1/4" thickness.

I'm pretty particular about how I assemble things. My method has always been to cut the baffles 1/8" narrow (1/16" each side) , to allow for expansion and to allow for silicone to fit between the baffles and the glass. I notch the bottom corners at an angle to allow the baffles to clear the existing silicone in the tank. Then mask off the 3 sides that will have silicone attached, leaving 1/2" where the silicone will be applied. Grab a dremel/rotary tool and a 1/2" sanding drum. Run the dremel on LOW speed and scuff all 3 edges (both sides... front and back) where the silicone will touch the baffle. This gives the silicone some ridges and roughness to grab onto and adhere too. Remove masking tape.

Clean with soap and water to remove sanding dust AND any residual oil or film from the manufacturing process. Dry thoroughly with paper towels, then use a hair dryer to be sure it's completely dry. I blast it with the hairdryer until its warm all around the edges where the silicone will be applied. It's dry now. Let it cool to room temperature.

I caulk both sides of each panel. Use your favorite tool or finger to squish the silicone in tightly and form a radius. I prefer a cheap plastic spoon.

Clean up with isopropyl alcohol (91%) and paper towels. Let it cure for at least 2 or 3 days.

Thank You for sharingI've installed acrylic/plexiglass baffles into many glass aquariums.

I always use ASI aquarium sealant. It's 100% silicone with no additives. $11 for a 10oz tube. Amazon.

I always use minimum 3/16" acrylic and prefer 1/4" thickness.

I'm pretty particular about how I assemble things. My method has always been to cut the baffles 1/8" narrow (1/16" each side) , to allow for expansion and to allow for silicone to fit between the baffles and the glass. I notch the bottom corners at an angle to allow the baffles to clear the existing silicone in the tank. Then mask off the 3 sides that will have silicone attached, leaving 1/2" where the silicone will be applied. Grab a dremel/rotary tool and a 1/2" sanding drum. Run the dremel on LOW speed and scuff all 3 edges (both sides... front and back) where the silicone will touch the baffle. This gives the silicone some ridges and roughness to grab onto and adhere too. Remove masking tape.

Clean with soap and water to remove sanding dust AND any residual oil or film from the manufacturing process. Dry thoroughly with paper towels, then use a hair dryer to be sure it's completely dry. I blast it with the hairdryer until its warm all around the edges where the silicone will be applied. It's dry now. Let it cool to room temperature.

I caulk both sides of each panel. Use your favorite tool or finger to squish the silicone in tightly and form a radius. I prefer a cheap plastic spoon.

Clean up with isopropyl alcohol (91%) and paper towels. Let it cure for at least 2 or 3 days.

How much room between the baffle and glass would you recommendThe GE silicone posted above bonds to glass and acrylic... I've done quite a few sumps with it and have yet to have a baffle leak, let alone fail. You do need to leave room for the acrylic to expand so it does not crack the glass though.

Zach B

Noo-Psyche Sales Rep

View Badges

Partner Member 2024

Excellence Award

UK Reef Club Member

Hospitality Award

Reef Tank 365 Boss

Wisco Reefers

Midwest Reefer

My Tank Thread

I believe I did mine with a "heavy" 16th of an inch on each side. The total was a "heavy" 8th of an inch. So just a little bit moreHow much room between the baffle and glass would you recommend

Similar threads

- Replies

- 40

- Views

- 425

- Replies

- 1

- Views

- 225

- Replies

- 3

- Views

- 126