I'm getting BRS's Dual reactor.

Trying to decide if I want to T off my quiet one 3000 return pump and then have the return of the reactors dump back into the sump or T off the sump and have the return of the reactors T back into pump return back to the tank.

I don't want to use a separate pump for the reactors because I have a very small return section of the sump (only about 6" x &.5") and it's kind of full with the quiet one 3000 and another pump for my NatuReef DeNitrification chamber.

It's already getting hard to get in there and remove the sponge separating the wet/dry section from the return section for cleaning, and as we all know the harder it is to do something the less likely we are going to do it, so I don't want to make it any harder.

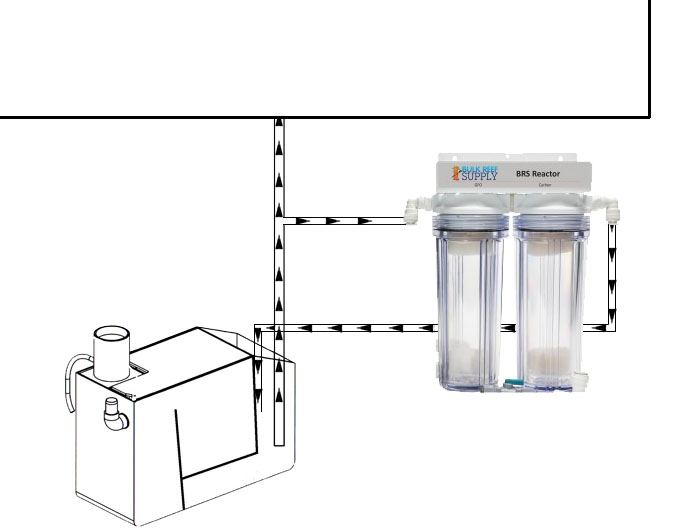

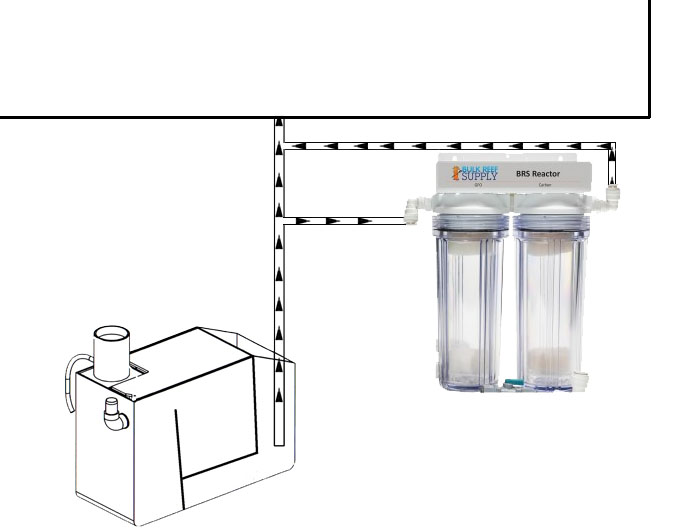

Here are my two options...

Return to Main Line

Or Return to Sump

Trying to decide if I want to T off my quiet one 3000 return pump and then have the return of the reactors dump back into the sump or T off the sump and have the return of the reactors T back into pump return back to the tank.

I don't want to use a separate pump for the reactors because I have a very small return section of the sump (only about 6" x &.5") and it's kind of full with the quiet one 3000 and another pump for my NatuReef DeNitrification chamber.

It's already getting hard to get in there and remove the sponge separating the wet/dry section from the return section for cleaning, and as we all know the harder it is to do something the less likely we are going to do it, so I don't want to make it any harder.

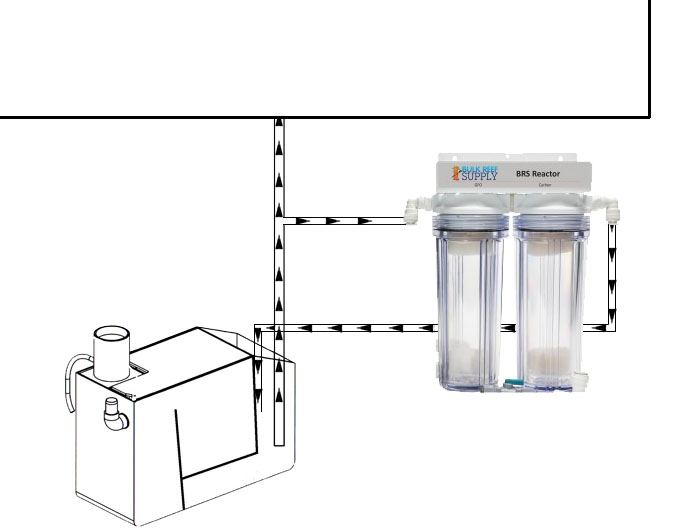

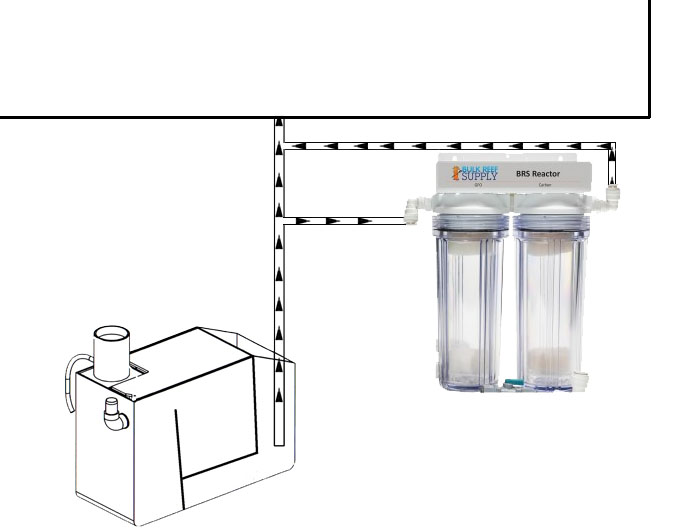

Here are my two options...

Return to Main Line

Or Return to Sump