- Joined

- Feb 27, 2018

- Messages

- 18

- Reaction score

- 4

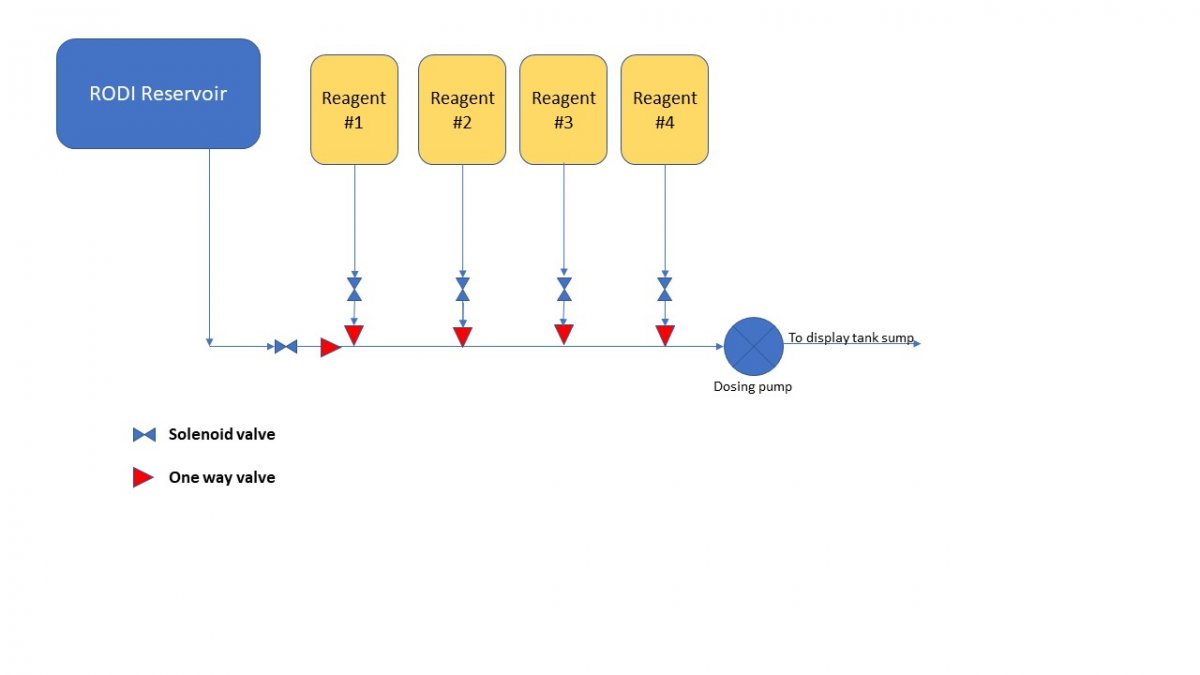

Hey everyone! I'm new to reefing and currently laying out a 300 gallon reef tank. I am leaning toward using the Triton method, dosing pump(s) and an Apex to control things. I want to put my dosing tanks and dosing pumps in a utility room that neighbors my display tank. My RODI system and utility sink are in that room. I'm wondering if I can use 1 dosing pump/line to dose RODI and the 4 Triton reagents. My thought is to run a 1/4 inch line from my RODI reservoir to the last stage of the display tank's sump. I would tee into that line with the different reagents and turn them on and off with solenoid valves. I attached a diagram of what that plumbing might look like. I know you can't mix the various reagents, so I would use the APEX to clear the line by pumping RODI after each reagent is dispensed. Doing so would fulfill my ATO and dispense the reagents through (1) 1/4" tube.

I am looking at doing it this way for a few reasons. First, it unclutters the display tank cabinet. Second, only one line would be required for the run to the display tanks, and third, solenoid valves are less expensive than multiple Dos pumps. Thoughts?

I am looking at doing it this way for a few reasons. First, it unclutters the display tank cabinet. Second, only one line would be required for the run to the display tanks, and third, solenoid valves are less expensive than multiple Dos pumps. Thoughts?