Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

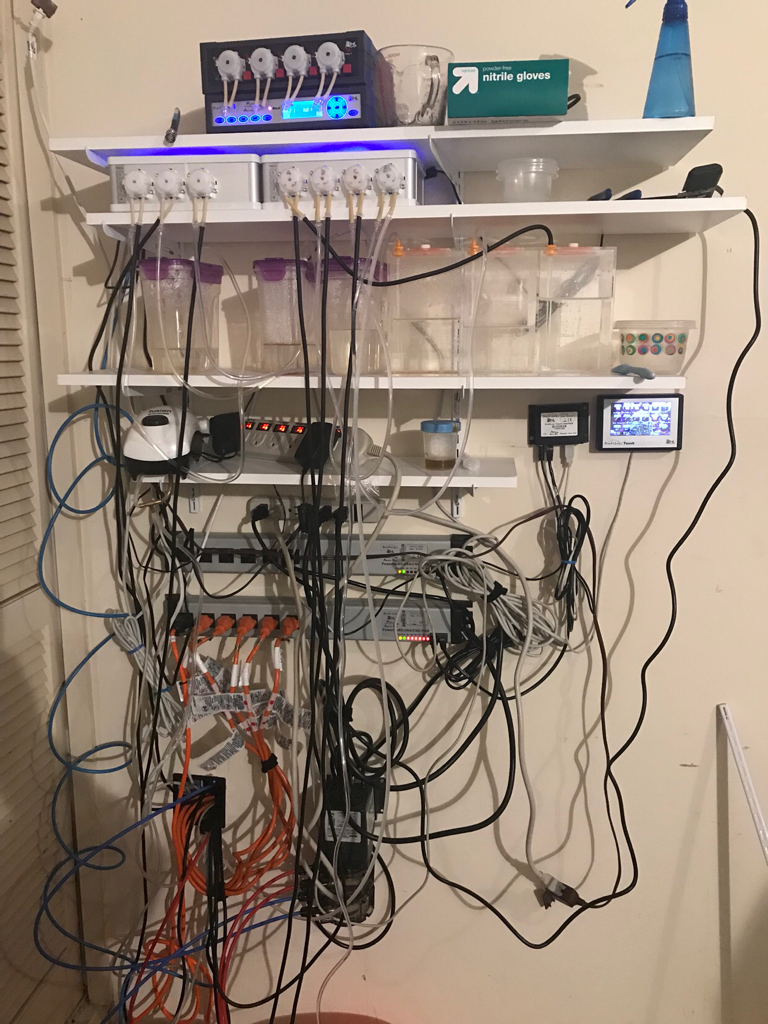

Very interesting concept. I would never do it with 2 part but I do like the idea for trace elements.Finally got around to testing this concept. The POC worked so well that I went ahead and plumbed it into my DT:

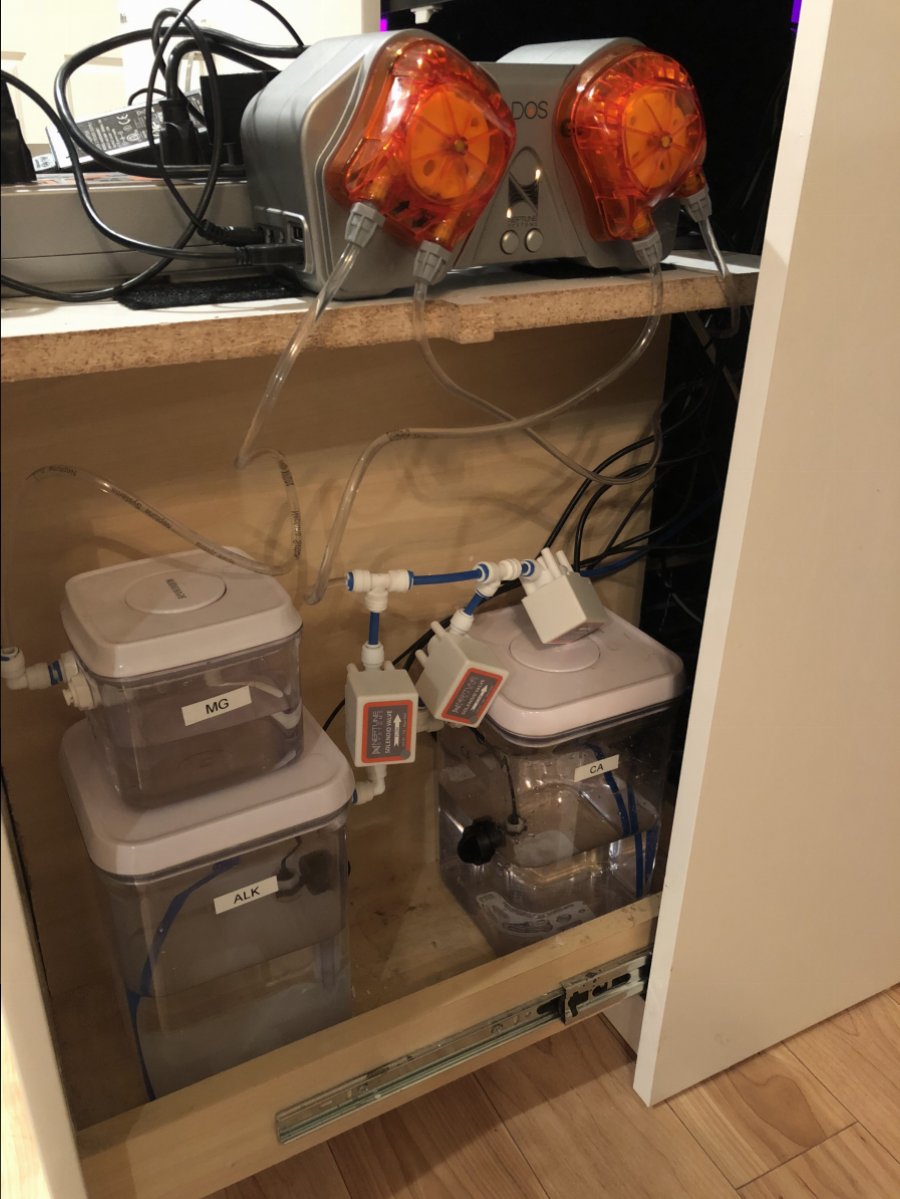

I put the ALK and CA on one pump, MG on the other for now. I could have put all three (or more) on one pump, but I only ordered three solenoids for the test.

Rather than draw from an ATO reservoir (which is out in the garage), I ended up just running the "flush" line back into my sump. No need to worry about any kind of salinity swing that way.

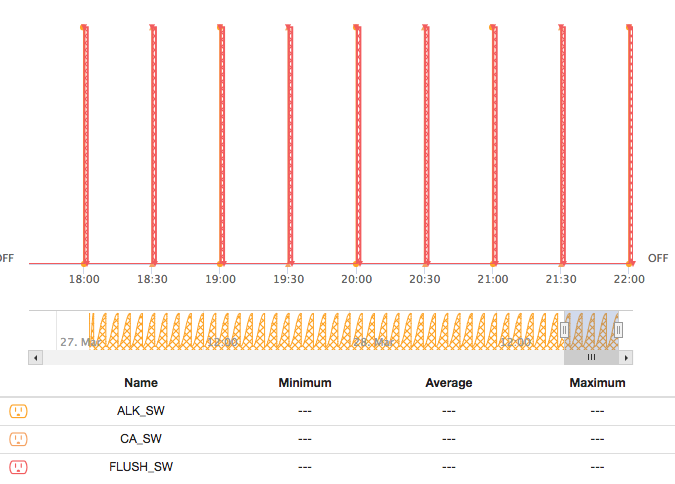

This is about as good a visual I can provide on how it's working:

Each spike is either ALK or CA (they alternate) followed by a "flush" execution.

The dosing time and amount is controlled using an "OSC" (oscillate) command as you would for a normal dosing pump program. Except instead of turning on a pump, it opens the appropriate solenoid. Any time a solenoid is open, the dosing pump turns on. The "flush" procedure is based on a "Min Time" command - a virtual outlet is told to open any time either the CA or ALK are open, with an additional "Min Time" to ensure that the entire line gets flushed (the DOS defaults to 25ml/min when told to just be "on"). The actual "flush" solenoid is hooked up to that virtual outlet, but also told to remain closed if either of the other two are open. The net result of this is that it stays closed while dosing the additive, and opens as soon as it's closed - remaining open for the remainder of the "Min Time" defined. Finally; I added in sensors to check the container levels; if they are empty, the solenoid stays closed (and I get an alert).

In the POC, I had a flow meter on the "out" side of the pump, but it never registered any flow. I'm pretty sure (reading the docs) that is due to it requiring a minimum pressure/flow rate - and the dosing pump just isn't getting there. Ah well; I wanted the flow meter for my RO/DI anyways.

If all I were doing with this were dosing in 2-part like this, it likely wouldn't be worth it cost-wise. But I can extend this system to include the four Triton additives I'm planning on simply by purchasing the additional solenoids (and a 1Link in order to get two more 24V outlets; I have 2 open in my current setup currently). I also don't get all the detailed reporting that the DOS can support if you use the normal method of programming it. Had I not already had the DOS, I likely would have just picked up a BRS top-off dosing pump and adjusted the timing (cut the "open" time in half since it's a 50mL/day pump).

Right now I am dosing saturated Kalkwasser and I dose 60 times a day for stability. Once I reach the limit of what I can add safely because of evaporation I will start incorporating 2 part and let it dose many times throughout the day.

When I start dosing trace elements, I will likely just spend the $400 on another 4 head GHL doser. If I still used an Apex, I would seriously have to consider something like this. Nice work!