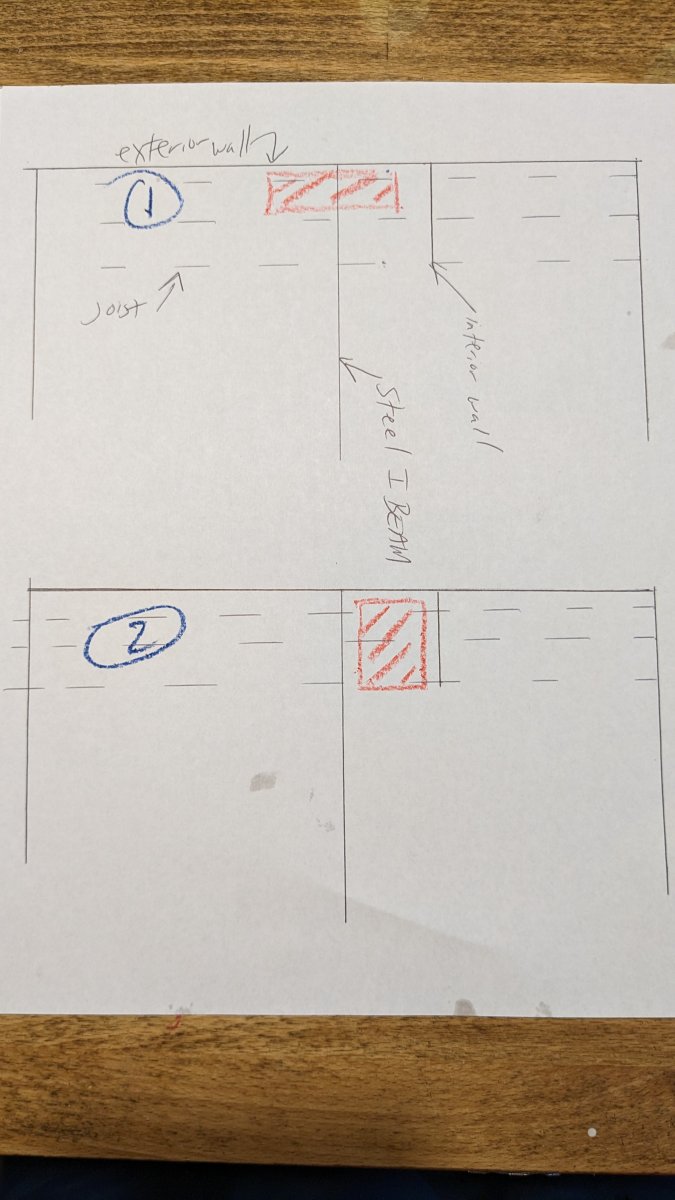

Looking for recommendations on best spot to place my 120g with 30g sump. 4x2 footprint. Joist are wood I joist with 2.5 inch flanges (10 inches tall I believe). 19.5 on center. Located on a raised crawl space. And due to HVAC runs it would be difficult to add additional support parallel to tank and steel I beam in #2. In #2 the steel I beam will be 6-10 inches in front of the front glass panel.

What's the best spot for support? And bonus if I don't need to add additional support.

And yes I realize only a engineer can give a definite answer but please post advice based on past experiences. I feel like a 120+sump is a very common size.

Edit: steel beam is existing from the builder (during construction)

What's the best spot for support? And bonus if I don't need to add additional support.

And yes I realize only a engineer can give a definite answer but please post advice based on past experiences. I feel like a 120+sump is a very common size.

Edit: steel beam is existing from the builder (during construction)

Last edited: