When i was testing it i still had it restricted the way i had it before. (Forgot that it was) so if i open it up all the way it should run smoothly u think?You could have the drains run into a sock, or foam, or a bucket. They will still be going down but will float to top and not make it into other sections or skimmer intake.

We did the math. That pump with that head should be perfect for your tank size. There’s no was that pump is putting up more than the two drains can handle. Add water if need be, it will level off.

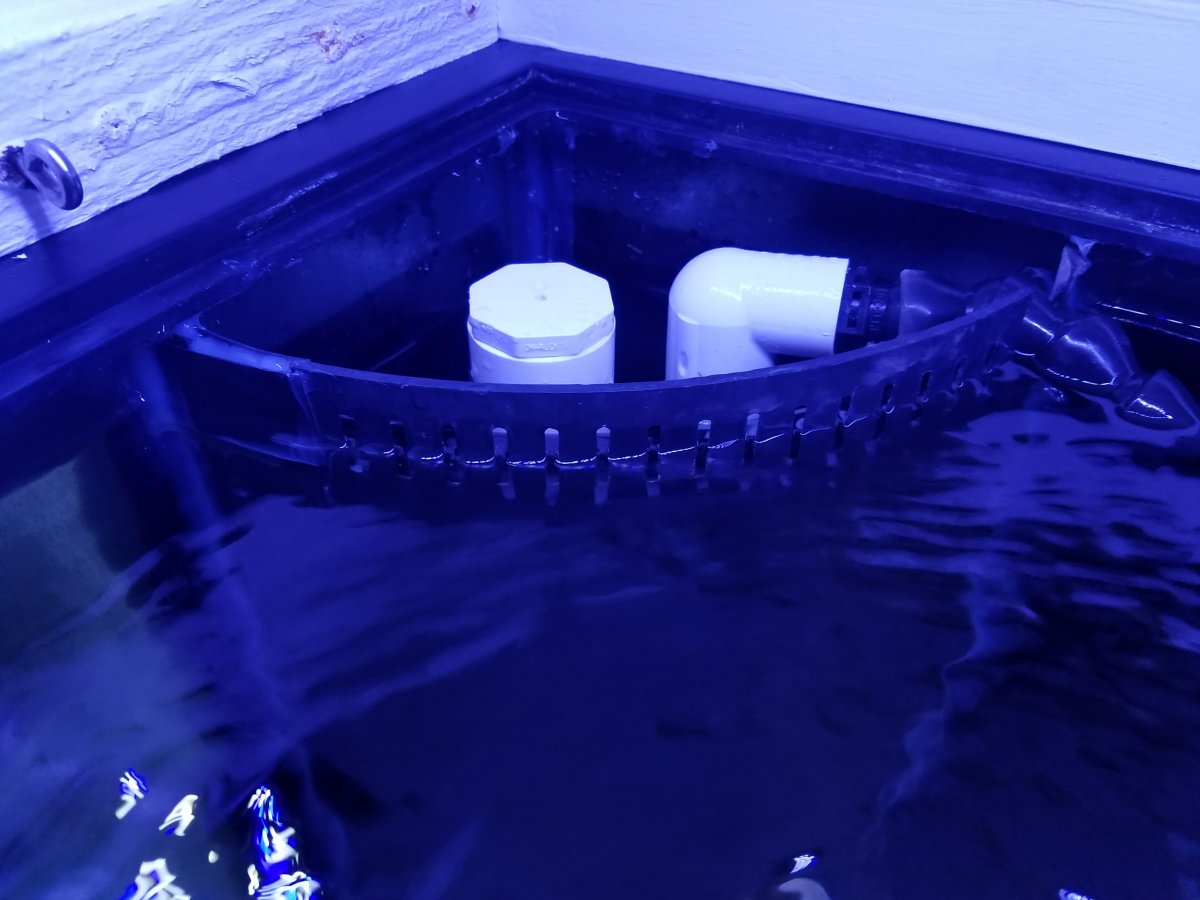

Make sure the weir on the overflows are clean

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can i quiet a noisy overflow?

- Thread starter Bthomas

- Start date

- Tagged users None

Ok system is running perfectly now. Im just really not to happy about the noise from the bubbles in the sump.

I saw someone else mention a tee with a couple inches of pipe going up from the top with a cap with a hole in it.. would this work along my straight horizontal pipe to let that air out before it reaches the sump?

I saw someone else mention a tee with a couple inches of pipe going up from the top with a cap with a hole in it.. would this work along my straight horizontal pipe to let that air out before it reaches the sump?

You can either extend the pipe or have it run into a sump sock to get rid of the bubbles. Alot of us use controllabe dc return pumps to where you can match the rate of return by turning the pump speed up or down. Before that we used a union valve after the return pump as you asked about. Return pumps do fine restricting the return flow. You are basically adding head pressure.

Last edited:

Thanks for the input but the sock wont get rid of the noise since the bubbles are still there just contained. I need a way of letting air out of the pipe before it reaches the sump if possibleYou can either extend the pipe or have it run into a sump sock to get rid of the bubbles. Alot of us use controllabe dc return pumps to where you can match the rate of return by turning the pump speed up or down. Before that we used a union valve after the return pump as you asked about. Return pumps do fine restricting the return flow. You are basically adding head pressure.

- Joined

- Oct 1, 2017

- Messages

- 3,060

- Reaction score

- 2,521

With a single pipe drain air must go down with water, therefore noise. You could do a diy stockman so at least you have a bit of control/adjustment and it will reduce but not eliminate noise

I dont know if you can eliminate the micro bubbles from a durso drain. If you look at my sump the whole purpose of the baffles is to keep the micro bubbles from making it to the return pump. It is called a bubble trap. I hope someone can chime in and help. It would be new to me also.

I managed to make mine totally silent by turning down my return pump, extending the return line a few inches below the waterline in the sump and adding a sump sock. The majority of flow in your tank should be coming from your powerheads.

Some people put air valves on them to fine tune the airflow and eliminate the flushing noise. I just drilled my durso with a smaller size hole.

Mine

I managed to make mine totally silent by turning down my return pump, extending the return line a few inches below the waterline in the sump and adding a sump sock. The majority of flow in your tank should be coming from your powerheads.

Some people put air valves on them to fine tune the airflow and eliminate the flushing noise. I just drilled my durso with a smaller size hole.

Mine

Last edited:

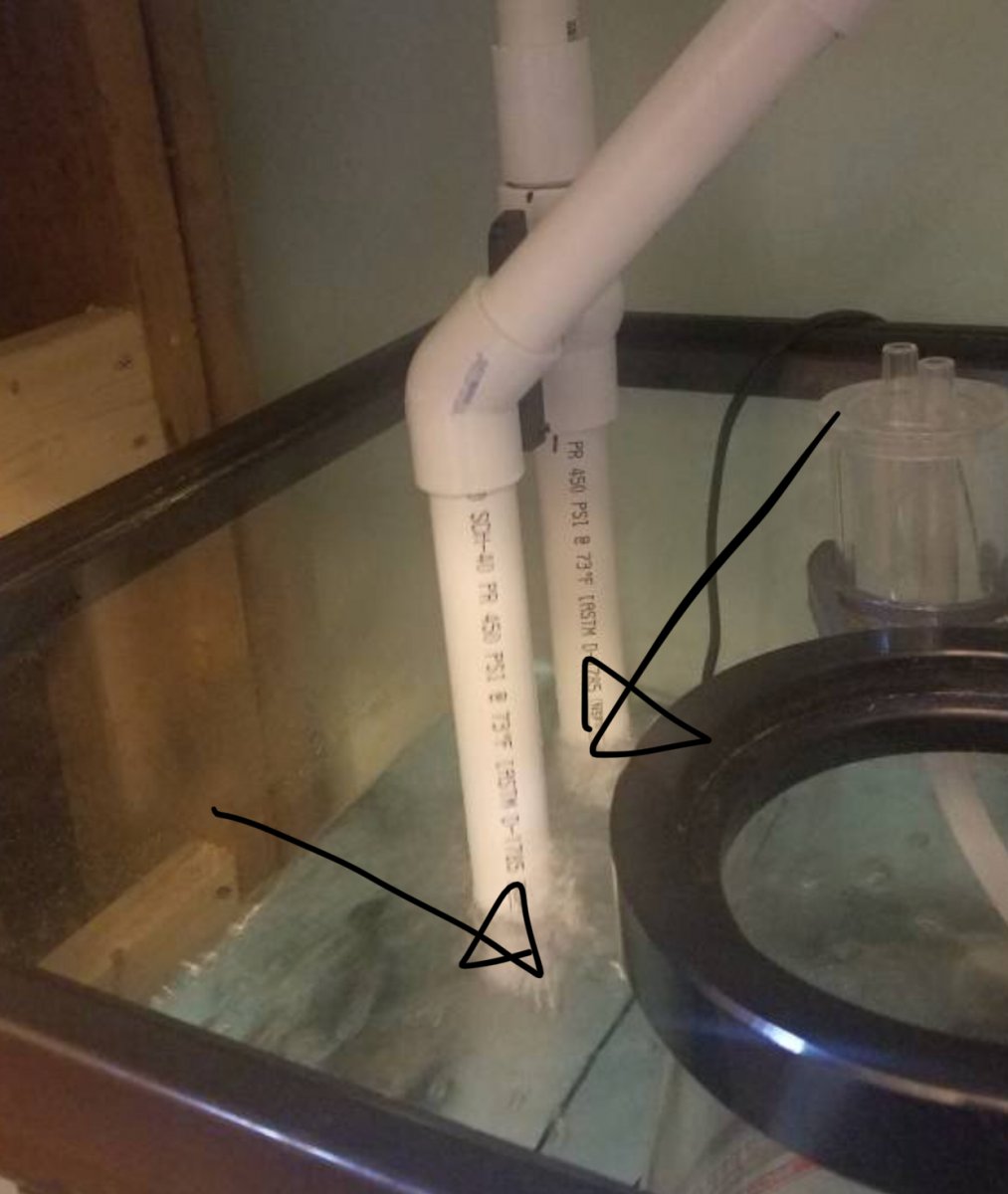

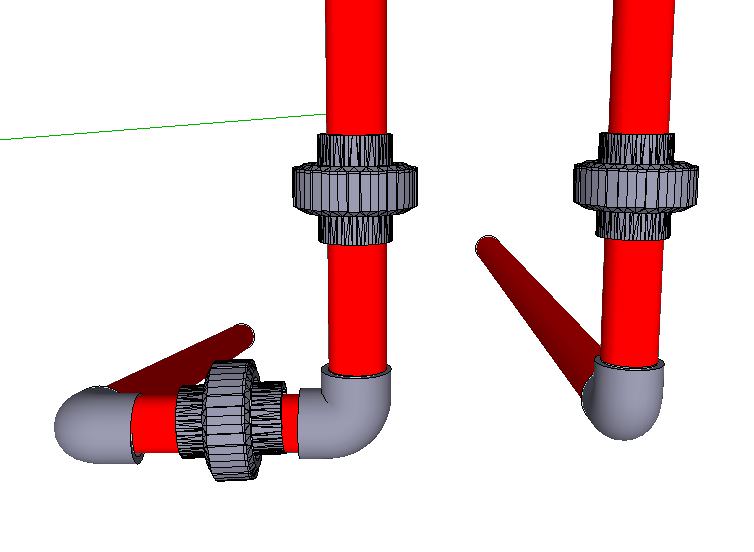

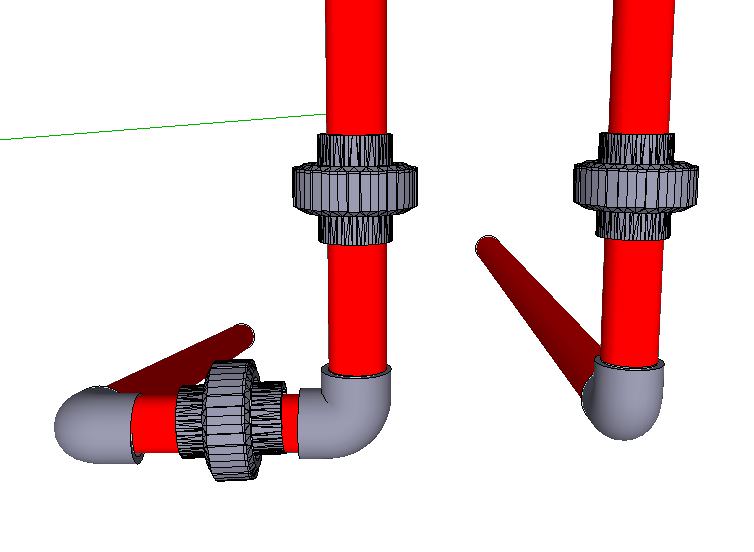

If it's trapped air inside the long horizontal pipe that's making noise I would add another union to that section (before the horizontal part and after the elbow). Then you should be able to get an angle on that pipe that would let air out more easily. Hope you understand what I mean...

Edit: Oh, and you'd need another elbow as well..

Edit: Oh, and you'd need another elbow as well..

Your system changed over the last few posts I read. Couple questions:

Is it possible to ditch your horizontal run and instead 45 it into your sump?

Earlier you mentioned one pipe is quiet and the other is now quieter, but there are still bubbles present in the sump. Are the bubbles coming from the pipe with the air valve in the top?

Do you have gate valves on the pipe(s) with an airline on the top?

Ideally, you should have your siphon drop straight into or 45’d into your sump without a horizontal run, with no gate valve or airline. A gate isn’t needed on a full siphon.

Your open channel(the one with an air valve) should have a gate on it and it should only handle the excess of what your siphon cannot. If you throw a gate on this pipe and adjust it so water is just “hugging” the sides of the pipe and not falling down the center your issue will be solved. No bubbles and tons of turnover. As mentioned earlier an emergency drain is nice to have but some consider it not necessary. ( I do)

Is it possible to ditch your horizontal run and instead 45 it into your sump?

Earlier you mentioned one pipe is quiet and the other is now quieter, but there are still bubbles present in the sump. Are the bubbles coming from the pipe with the air valve in the top?

Do you have gate valves on the pipe(s) with an airline on the top?

Ideally, you should have your siphon drop straight into or 45’d into your sump without a horizontal run, with no gate valve or airline. A gate isn’t needed on a full siphon.

Your open channel(the one with an air valve) should have a gate on it and it should only handle the excess of what your siphon cannot. If you throw a gate on this pipe and adjust it so water is just “hugging” the sides of the pipe and not falling down the center your issue will be solved. No bubbles and tons of turnover. As mentioned earlier an emergency drain is nice to have but some consider it not necessary. ( I do)

This is exactly the issue but im not sure im following what you mean here..If it's trapped air inside the long horizontal pipe that's making noise I would add another union to that section (before the horizontal part and after the elbow). Then you should be able to get an angle on that pipe that would let air out more easily. Hope you understand what I mean...

Edit: Oh, and you'd need another elbow as well..

Also its not micro bubbles im getting its large noisey bubbles

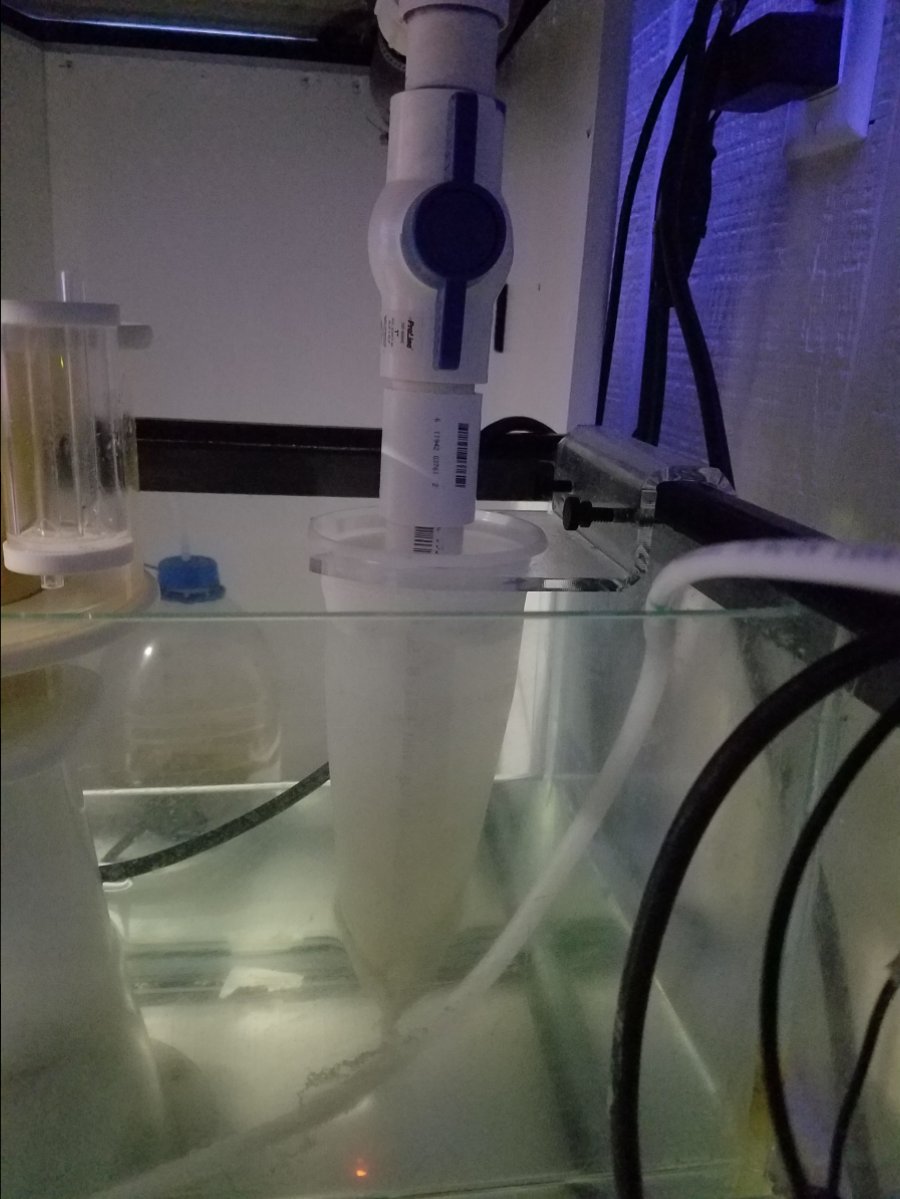

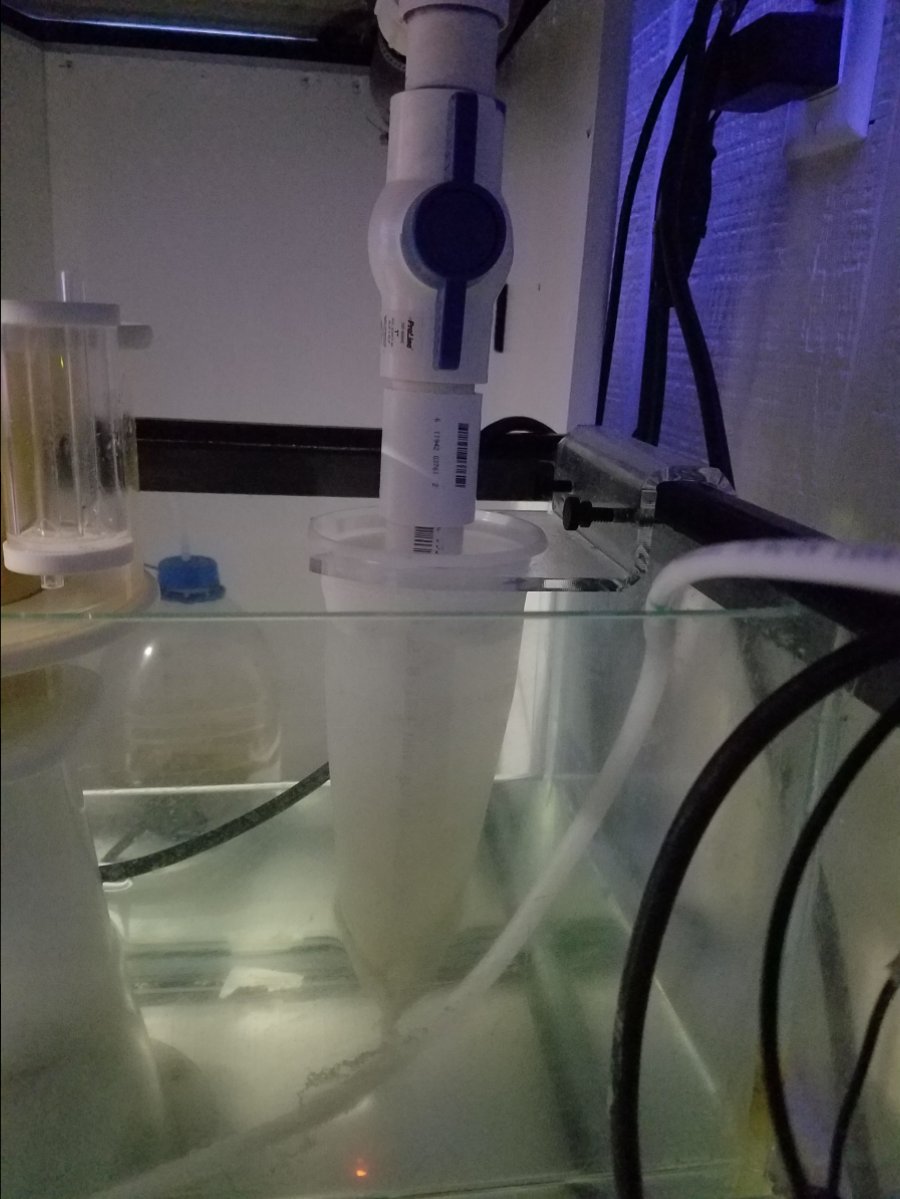

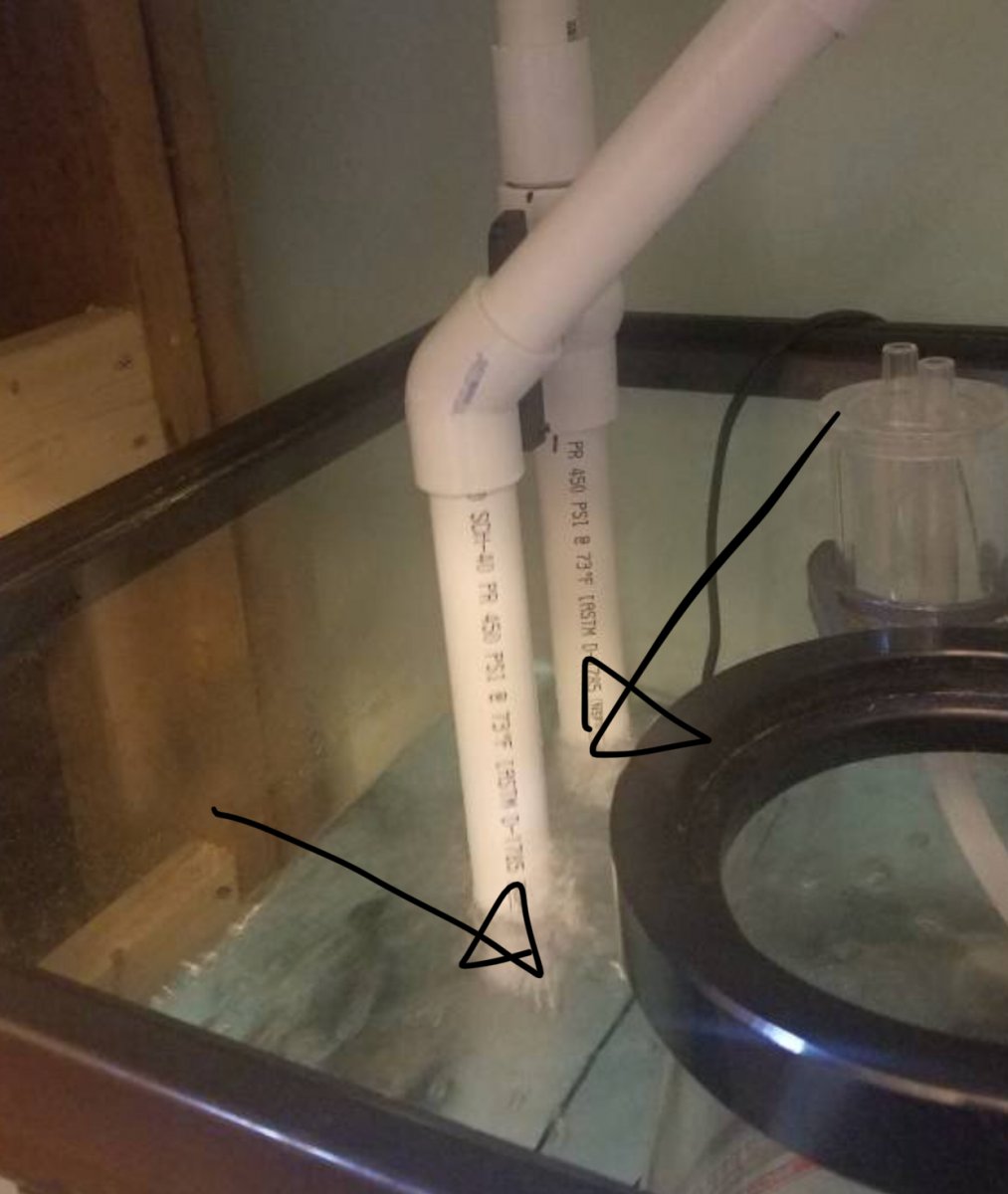

Just noticed your drains. They terminate too far into the sump. Which causes cavitation and startup issues with the siphon.

I would trim them down. Either remove the pipes and cut them, or if they’re glued( which they should be) take a hacksaw blade( without the saw) and use it to cut the bottoms of your standpipes so they terminate a half inch into the waterline. Or adjust the water level in your sump to achieve the same goal.

I would trim them down. Either remove the pipes and cut them, or if they’re glued( which they should be) take a hacksaw blade( without the saw) and use it to cut the bottoms of your standpipes so they terminate a half inch into the waterline. Or adjust the water level in your sump to achieve the same goal.

Did a quick sketch in Sketchup. Don't know if you have room for it though.

I cant get rid of the horizontal.. the pipe wont make it to the first section of my sump without it. I did do the last bit of it at 45 degrees hoping that would quiet it but it did not.Your system changed over the last few posts I read. Couple questions:

Is it possible to ditch your horizontal run and instead 45 it into your sump?

Earlier you mentioned one pipe is quiet and the other is now quieter, but there are still bubbles present in the sump. Are the bubbles coming from the pipe with the air valve in the top?

Do you have gate valves on the pipe(s) with an airline on the top?

Ideally, you should have your siphon drop straight into or 45’d into your sump without a horizontal run, with no gate valve or airline. A gate isn’t needed on a full siphon.

Your open channel(the one with an air valve) should have a gate on it and it should only handle the excess of what your siphon cannot. If you throw a gate on this pipe and adjust it so water is just “hugging” the sides of the pipe and not falling down the center your issue will be solved. No bubbles and tons of turnover. As mentioned earlier an emergency drain is nice to have but some consider it not necessary. ( I do)

That horizontal pipe is the issue tho.. the overflow from the other chamber that is dropping straight down is not producing bubbles.

I do not have any gate valves on these pipes. The one thats not the problem does have a ball valve but im not using it

How would this help with the bubbles?Did a quick sketch in Sketchup. Don't know if you have room for it though.

Is this related to the bubble noise or just an unrelated issue i should take care of lolJust noticed your drains. They terminate too far into the sump. Which causes cavitation and startup issues with the siphon.

I would trim them down. Either remove the pipes and cut them, or if they’re glued( which they should be) take a hacksaw blade( without the saw) and use it to cut the bottoms of your standpipes so they terminate a half inch into the waterline. Or adjust the water level in your sump to achieve the same goal.

I had them go down a little farther thinking that would help with bubbles

This is where i got the idea to use a Tee with an air release at the top along the vertical pipe.The gurgling is trapped air. I had a similar setup to this several years ago. I was able to quiet it by using a “4 way” of 1.5” instead of a 1” “T” where the two drains join. The “top” of the “4 way” was a few inches of pipe going up with a cap that had a hole drilled in it. The larger diameter pipe where they joined coupled with the “air release” made it far quieter.

-Ed

Any chance that would work?

How would this help with the bubbles?

It was a way to get an angle on that horizontal pipe that could hopefully help with getting rid of the trapped air. From what I've heard that could be a problem with longer sections of horizontal pipes.

Put your hand under the pipe that’s not causing issues. Is it a strong full siphon?I cant get rid of the horizontal.. the pipe wont make it to the first section of my sump without it. I did do the last bit of it at 45 degrees hoping that would quiet it but it did not.

That horizontal pipe is the issue tho.. the overflow from the other chamber that is dropping straight down is not producing bubbles.

I do not have any gate valves on these pipes. The one thats not the problem does have a ball valve but im not using it

Then feel the flow under the pipe with an air valve causing noise/ bubbles. Is it also strong flow or is it barely strong enough to feel? If this pipe has strong flow, it shouldn’t and there’s your problem.

This can be fixed by a gate (or a ball) on this channel.

I’d also experiment valving down the return pump (on the output side) and trying to tune it so that you have a full siphon in pipe 1, and just a little extra flow in pipe2( the one with the air valve)

That would also potentially solve the issue.

The horizontal pipe would still be just as long tho with that setup unless im missing somethingIt was a way to get an angle on that horizontal pipe that could hopefully help with getting rid of the trapped air. From what I've heard that could be a problem with longer sections of horizontal pipes.

The horizontal pipe would still be just as long tho with that setup unless im missing something

The problem could be that it's horizontal with no angle to it. The air is just stuck to the roof of the pipe. With an angle the air would travel upwards and out.

Similar threads

- Replies

- 5

- Views

- 131

- Replies

- 6

- Views

- 118

- Replies

- 14

- Views

- 361

- Replies

- 4

- Views

- 230