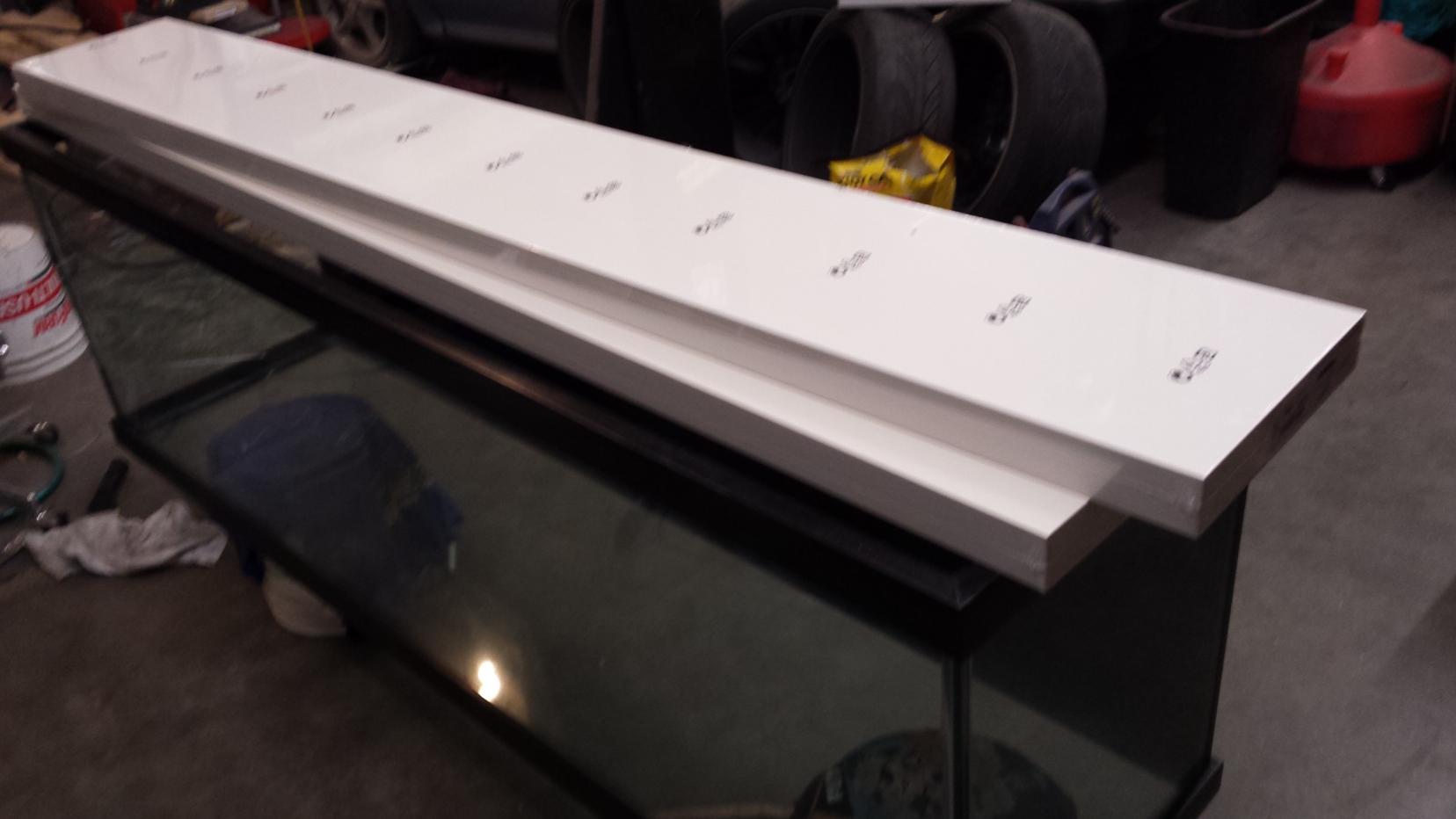

after loosing a bid on ebay for a marineland light fixture for a lot of money i gave up and built my own. just kind of an idea to aesthetically hold some ebay led flood light fixtures.

so the inside of the shelves are honey comb cradboard, there is some wood mdf i think two in the middle were there bracket rods hold the shelve two strips at the ends and one running down the back of the shelve that would sit against the wall. if you hit them it will be a pain, my lights laid out to miss them, but on dif. sized shelve dif. number of lights id could lay out right on them and make things impossible and or weaken the shelve a lot. I decided to rip out the cardboard near my holes and great stuff the inside, wich is a lot harder to get the great stuff to stay in then you would think, ideally you could build some type of false wall around the hole to help it fill in stronger but i didnt want to spend the time as i wasnt sure if this whole thing was going to work in the first place. i used a hole saw that we had it was so dull it would actually throw sparks of the plastic lol, but it was the onlly one i had that would fit the recessed light trims.

the image uplaoder stinks so multiple post write up, please dont comment there is alot more and id like it to be in a row, it is going to take a while the way this thing is going

so the inside of the shelves are honey comb cradboard, there is some wood mdf i think two in the middle were there bracket rods hold the shelve two strips at the ends and one running down the back of the shelve that would sit against the wall. if you hit them it will be a pain, my lights laid out to miss them, but on dif. sized shelve dif. number of lights id could lay out right on them and make things impossible and or weaken the shelve a lot. I decided to rip out the cardboard near my holes and great stuff the inside, wich is a lot harder to get the great stuff to stay in then you would think, ideally you could build some type of false wall around the hole to help it fill in stronger but i didnt want to spend the time as i wasnt sure if this whole thing was going to work in the first place. i used a hole saw that we had it was so dull it would actually throw sparks of the plastic lol, but it was the onlly one i had that would fit the recessed light trims.

the image uplaoder stinks so multiple post write up, please dont comment there is alot more and id like it to be in a row, it is going to take a while the way this thing is going