Good evening R2R, my name is Joel and I'm a reef addict

My family and I have been keeping reefs for years (though there was a few years between tanks) and we're proud owners of two reef tanks currently including a standard 90G and a Reefer 170, the latter of which we documented here on R2R. For the longest time, I'm dreamed of owning a massive reef system and have never had the time, budget, or frankly space to make it happen. A few months ago a causal conversation with my lovely wife turned into the blueprint for creating this dream tank in our house. Yesterday we plopped down untold amounts of (presumably) fresh Benjamin's for deposits on our custom tank and I can now officially say, the build has begun!

for deposits on our custom tank and I can now officially say, the build has begun!

To give you a little background on how we got here:

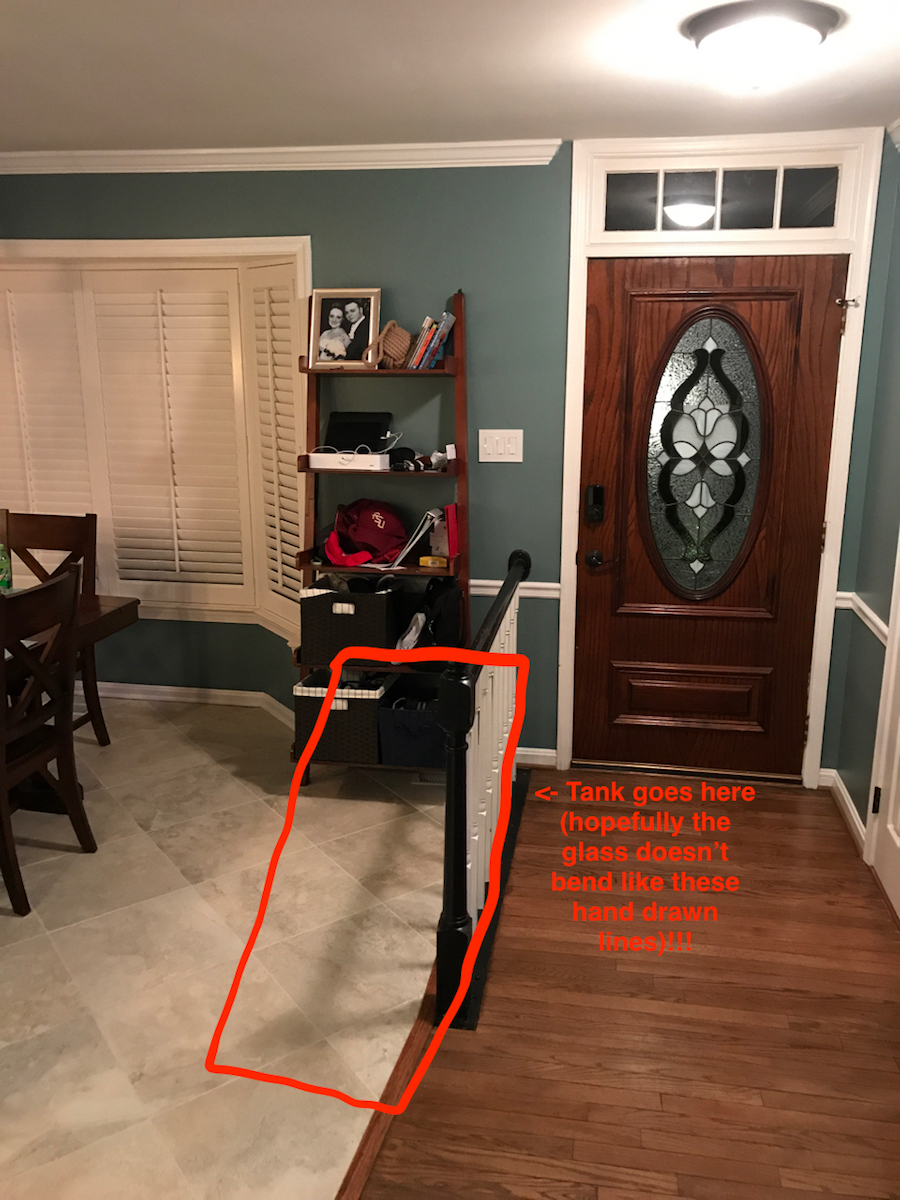

To start this off right, here's a few pics of what we've done in the past few days including a picture of the ultimate location (it's going to be a room divider between our front door and dining room), a picture of my son helping paint the stand which will house the water mixing station currently under construction, and my son also "vanna white-ing" the first shipment which was primarily supplies for the mixing station!

Looking forward to sharing the journey with my fellow reefers!

My family and I have been keeping reefs for years (though there was a few years between tanks) and we're proud owners of two reef tanks currently including a standard 90G and a Reefer 170, the latter of which we documented here on R2R. For the longest time, I'm dreamed of owning a massive reef system and have never had the time, budget, or frankly space to make it happen. A few months ago a causal conversation with my lovely wife turned into the blueprint for creating this dream tank in our house. Yesterday we plopped down untold amounts of (presumably) fresh Benjamin's

To give you a little background on how we got here:

- We didn't want yet "another" tank, so we wanted a tank that was big enough to allow for us to consolidate our existing tanks into it and also give us the room to grow substantially - both in terms of corals (which my wife loves) and fish (which I love).

- I have been a big fan of peninsula style tanks both in terms of aesthetics and function. I also love the rimless design - thanks Red Sea - but quickly realized there were limitations to this style even in the custom designed arena which I discussed briefly on this thread.

- As much as I love our tanks and inhabitants, I hated the maintenance particularly water changes. So in the new tank I wanted as much automation as possible and, of course, never wanted to haul another 5G bucket up what in some cases was multiple sets of stairs.

- The tank is going to be a peninsula style, 72" long x 30" wide x 36" deep all glass aquarium with starphire (low-iron) glass on the 3 viewing sides bring us to approximately 336 gallons in the DT.

- The tank will be placed on our second floor and all plumbing will run down to a basement sump designed / manufactured by Synergy Reef. For those wondering, we chose their SS-48 model which is not listed on their website but is the same design as what was used for the @Bulk Reef Supply 160 (which is a great series if you haven't checked it out)

To start this off right, here's a few pics of what we've done in the past few days including a picture of the ultimate location (it's going to be a room divider between our front door and dining room), a picture of my son helping paint the stand which will house the water mixing station currently under construction, and my son also "vanna white-ing" the first shipment which was primarily supplies for the mixing station!

Looking forward to sharing the journey with my fellow reefers!