I had my SCA 150 set up for 10 months and had to break it down at the end of August '19 to move from Georgia to Michigan. Here is my original build thread: https://www.reef2reef.com/threads/matts-natural-reef.488794/

I decided to move the tank and stand together by lifting the stand with a hydraulic duck bill jack high enough to get 2 - 4 wheel furniture dollies under the stand and using ratchet straps vertically around the dollies, stand, and tank. I removed all of the rock into plastic totes for the move through the house and into th back of the Uhaul. I didn't remove the sand which probably weighed 200 lbs which made the transfer much harder. Once the tank was in place ratchet strapped the tank and stand horizontally to the slats that run horizontally along the inside of the box truck. Then I added the rock and enough water to cover the rock in order to keep the surfaces "wet".

During the planning for this move I considered transporting my livestock in the tank partially filled with water or transporting in sealed buckets. It was suggested to me that the sloshing of the water during the moving of the truck would cause too much stress for the livestock so I choose to transport them in a bucket with some sand and rock. It took several days to finish packing the truck so I kept a powerhead on low and a heater in the bucket with the livestock until we were ready to go. I also took the bucket into the hotel room when we stopped to sleep to run the powerhead while we slept. Upon arriving at my new apartment late at night I brought the bucket in and added the powerhead and heater. The next morning I start moving the stuff in which is blocking in my tank so I can hurry up and get my tank set back up. That's when I discovered that my daughter's skateboard had shifted during transport and chipped the top inch of the side panel. Needless to say I was heartbroken. So after a little sulking about my broken tank I decided to turn one of the two 55 gallon pickle drums I picked up for my planned basement water change station and use it for a temporary holding tank for all of my displaced refugees. I transferred the sand and rock from the now broken DT and made up some fresh IO with a couple powerheads and a heater. I had a nice surprise while moving the sand over and found Stache my lawnmower Blenny alive buried in the sand. Now for the rest of the bad news for my move....I transfer the bucket with my livestock to find all but my Canarie Gobie have perished (he ended up in a different bucket, one without powerheads or heaters).

Before water:

Before move:

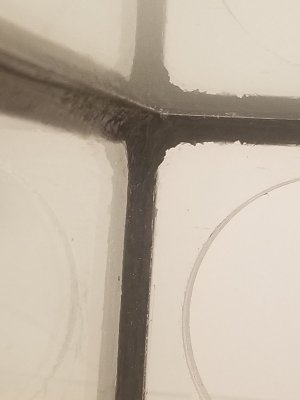

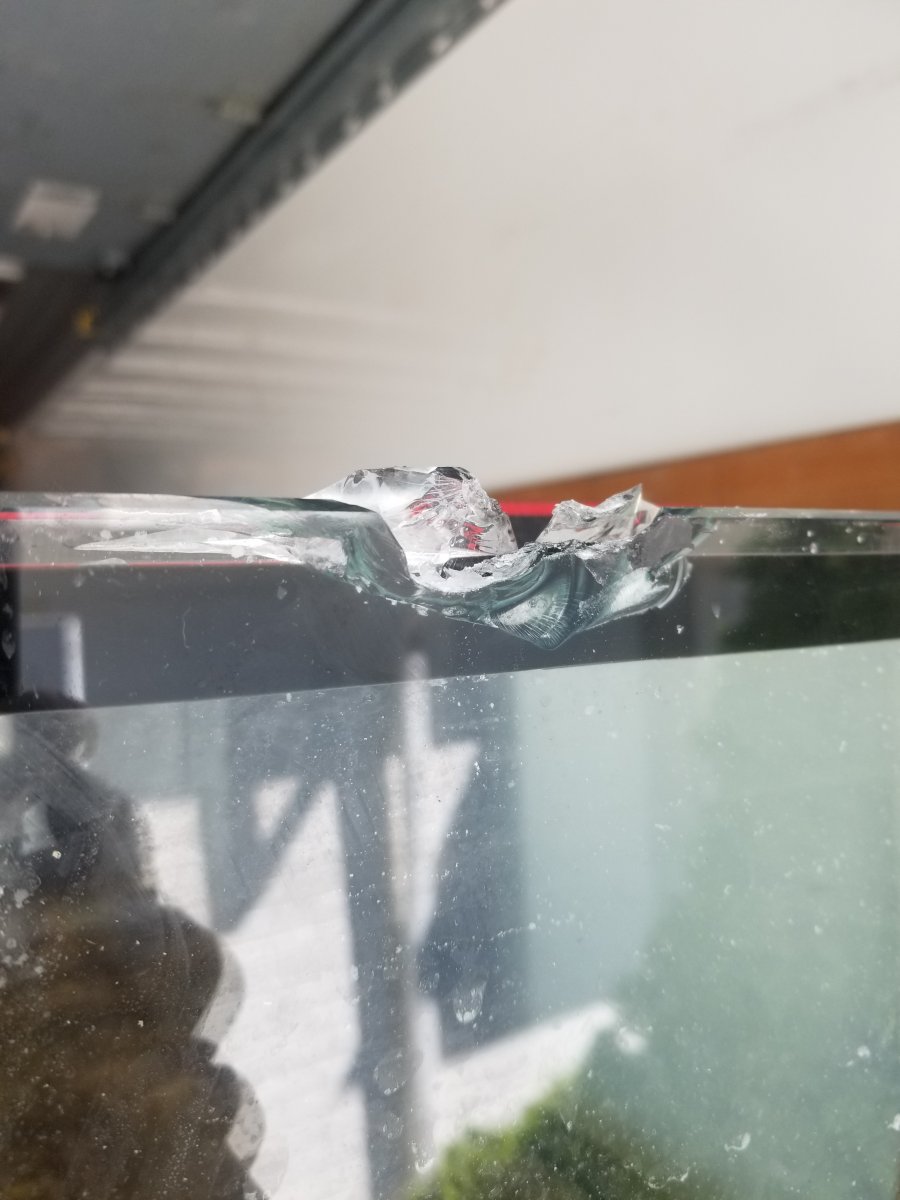

After break:

WET AGAIN FINALLY!!!

9/14/2022

9/14/2022

I decided to move the tank and stand together by lifting the stand with a hydraulic duck bill jack high enough to get 2 - 4 wheel furniture dollies under the stand and using ratchet straps vertically around the dollies, stand, and tank. I removed all of the rock into plastic totes for the move through the house and into th back of the Uhaul. I didn't remove the sand which probably weighed 200 lbs which made the transfer much harder. Once the tank was in place ratchet strapped the tank and stand horizontally to the slats that run horizontally along the inside of the box truck. Then I added the rock and enough water to cover the rock in order to keep the surfaces "wet".

During the planning for this move I considered transporting my livestock in the tank partially filled with water or transporting in sealed buckets. It was suggested to me that the sloshing of the water during the moving of the truck would cause too much stress for the livestock so I choose to transport them in a bucket with some sand and rock. It took several days to finish packing the truck so I kept a powerhead on low and a heater in the bucket with the livestock until we were ready to go. I also took the bucket into the hotel room when we stopped to sleep to run the powerhead while we slept. Upon arriving at my new apartment late at night I brought the bucket in and added the powerhead and heater. The next morning I start moving the stuff in which is blocking in my tank so I can hurry up and get my tank set back up. That's when I discovered that my daughter's skateboard had shifted during transport and chipped the top inch of the side panel. Needless to say I was heartbroken. So after a little sulking about my broken tank I decided to turn one of the two 55 gallon pickle drums I picked up for my planned basement water change station and use it for a temporary holding tank for all of my displaced refugees. I transferred the sand and rock from the now broken DT and made up some fresh IO with a couple powerheads and a heater. I had a nice surprise while moving the sand over and found Stache my lawnmower Blenny alive buried in the sand. Now for the rest of the bad news for my move....I transfer the bucket with my livestock to find all but my Canarie Gobie have perished (he ended up in a different bucket, one without powerheads or heaters).

Before water:

Before move:

After break:

WET AGAIN FINALLY!!!

9/14/2022

9/14/2022

Last edited: