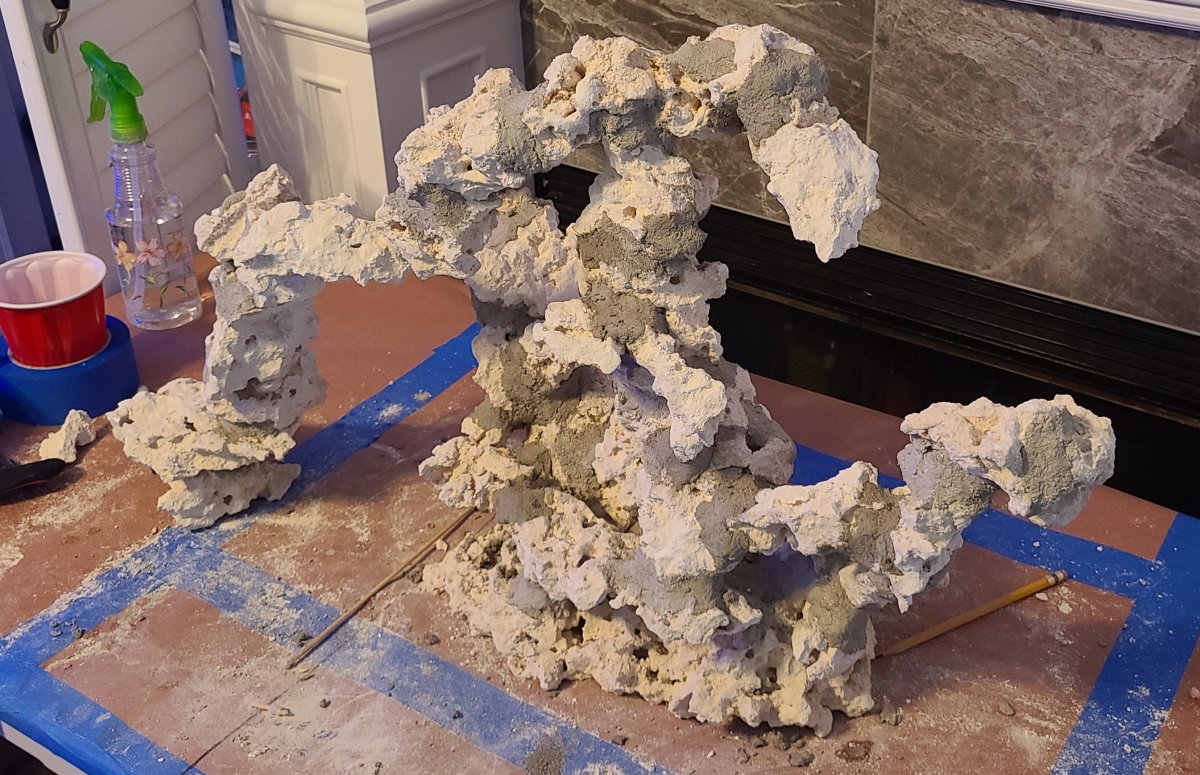

Right hand side Aquascape. Have 2 more to build which will occupy the left 4 feet of the tank. This one has the joints mortared, but I have not added sand to cover the joints... Will do all 3 at once since I think it will be a very messy job. Left side of the arch is not connected yet... will glue that once I have it in the tank.

Tried to make sure I had some ledges and caves which don't show up too well in the pics

Took me about 8 hours to build this, but a lot of that time was sitting there staring at it, trying to figure out where the next piece goes. For me, I never worked more than an hour at a time, so everything could "cure" before I moved on and I could think about where the next set of rocks were going.

This took 1 x 10oz of BRS glue, 2 x 2OZ bottles of glue accelerator (Insta-Set) and about 70% of an EMarco-400 Mortar container. My estimate is that there is about 25-30lbs of rock.

Definitely helps that my tank is still 6-8 weeks out, so I don't feel rushed to complete it.

Tried to make sure I had some ledges and caves which don't show up too well in the pics

Took me about 8 hours to build this, but a lot of that time was sitting there staring at it, trying to figure out where the next piece goes. For me, I never worked more than an hour at a time, so everything could "cure" before I moved on and I could think about where the next set of rocks were going.

This took 1 x 10oz of BRS glue, 2 x 2OZ bottles of glue accelerator (Insta-Set) and about 70% of an EMarco-400 Mortar container. My estimate is that there is about 25-30lbs of rock.

Definitely helps that my tank is still 6-8 weeks out, so I don't feel rushed to complete it.