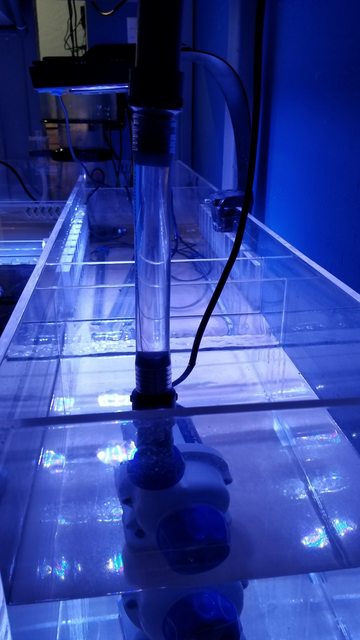

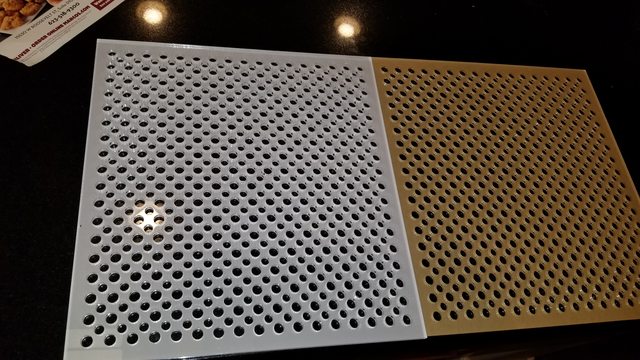

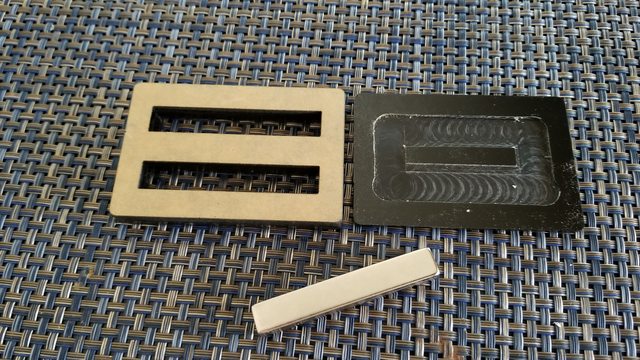

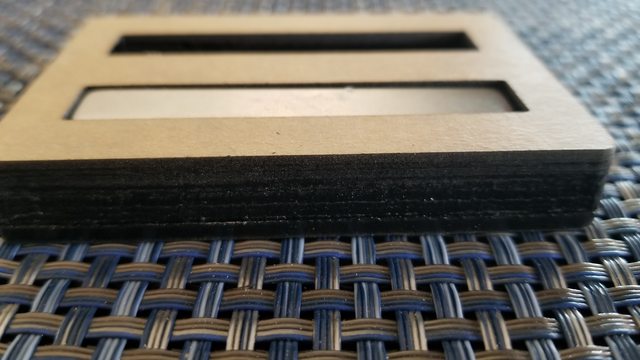

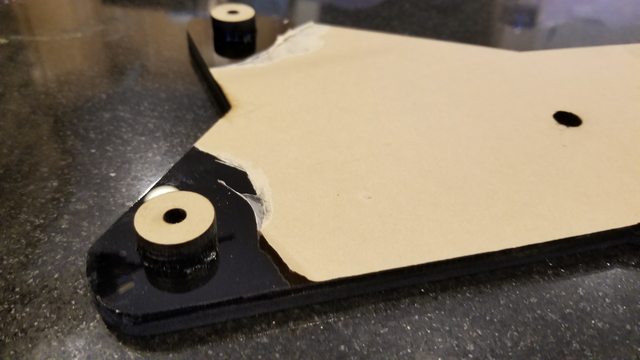

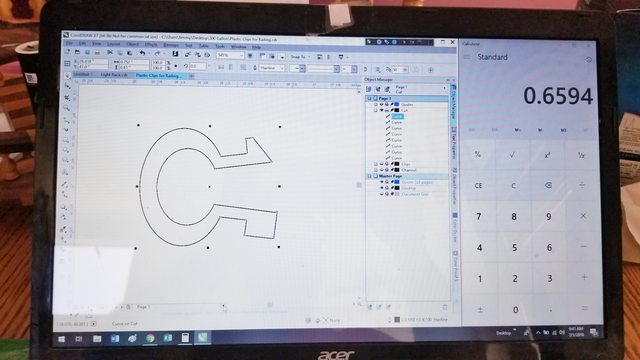

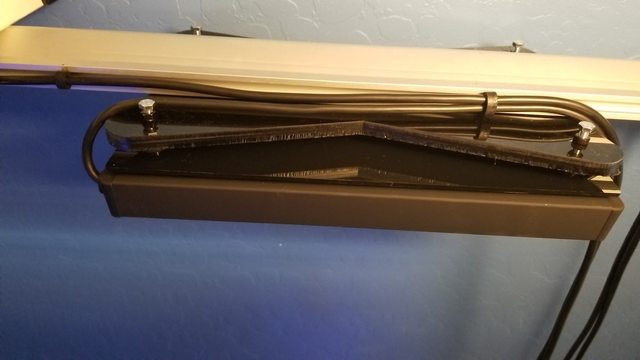

Since I re-aligned my laser it has been slicing through acrylic like butter. The filter sock cover is layered with 1/4" black, 3/8" clear and another 1/4" black, that's 7/8" thick piece that it had to cut through to make this hole for the uniseal.

And just like that:

1. Build and paint the platform under the tank for the sump DONE

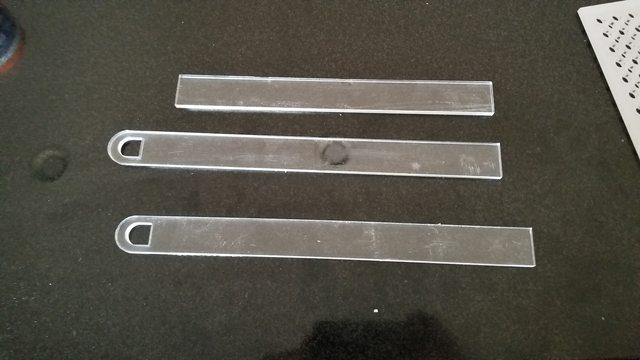

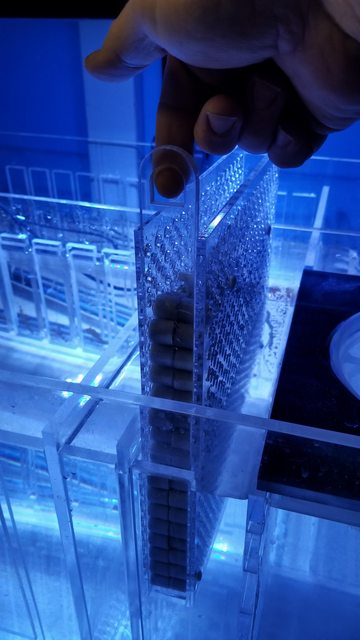

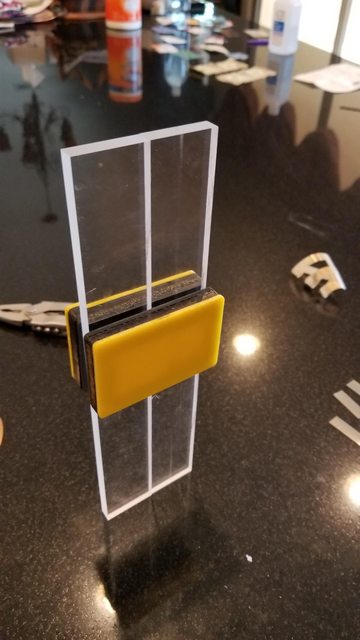

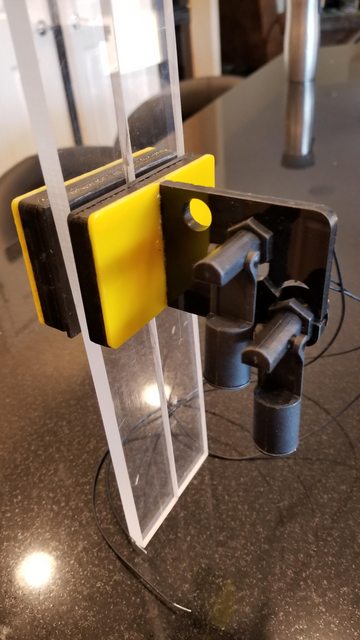

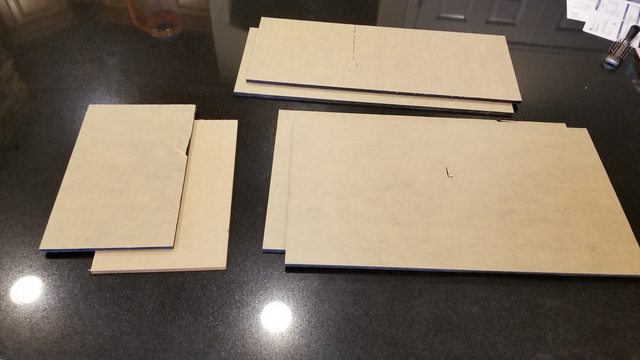

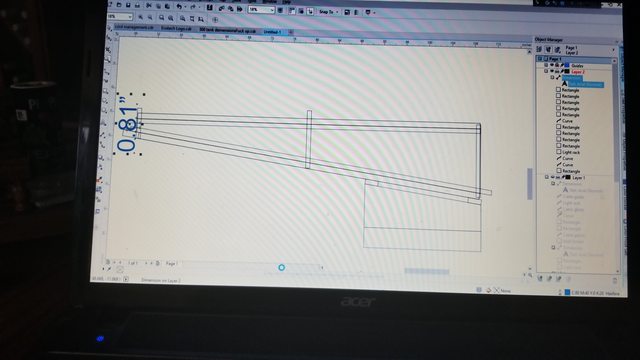

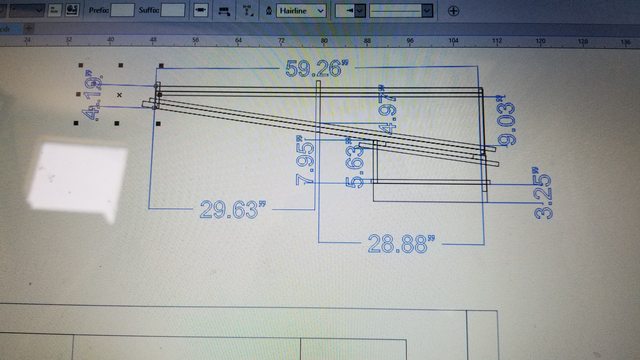

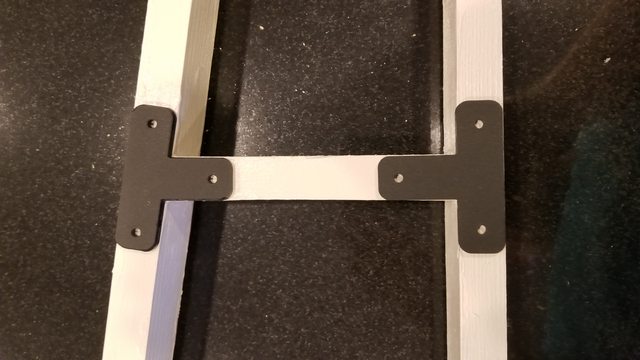

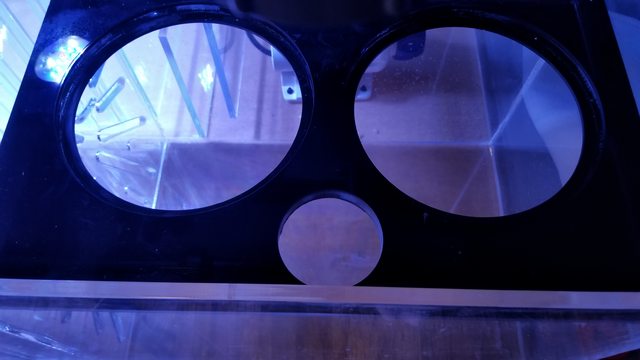

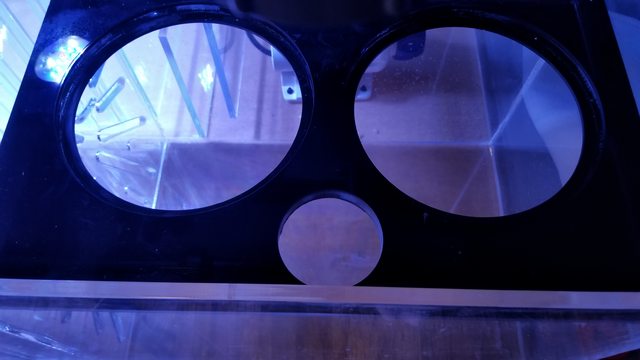

2. Cut out the acrylic for the ghost overflow DONE

3. Glue the overflow DONE

4. Drill holes in the tank for the overflow DONE

5. Drill holes in the tank for the returns DONE

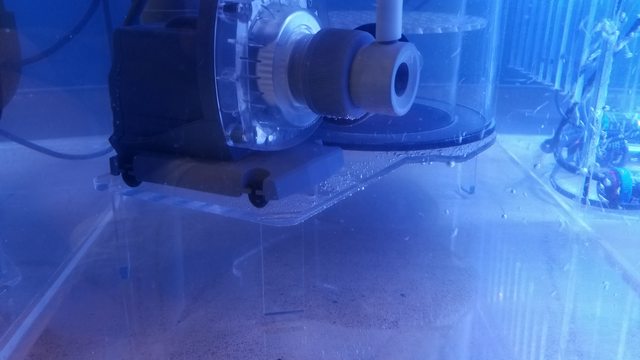

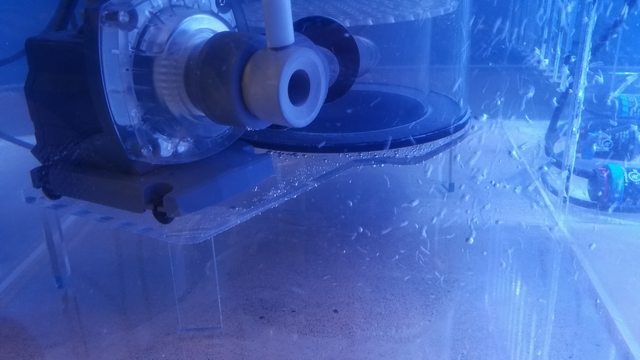

6. Cut and glue all the plumbing for the drain and return DONE

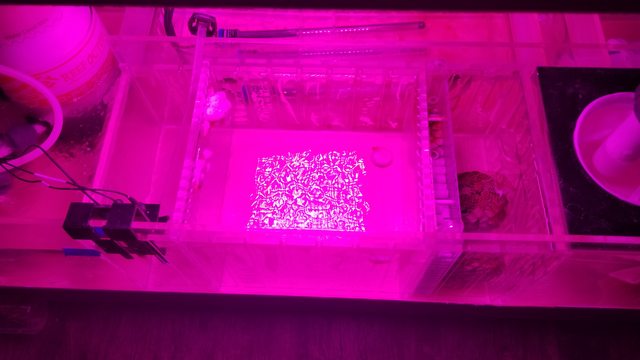

I mapped out the inside of the tank foot print

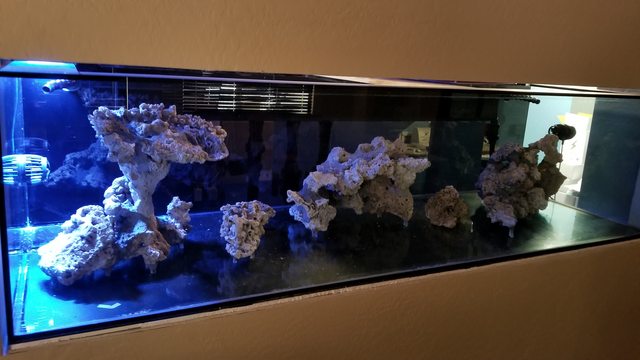

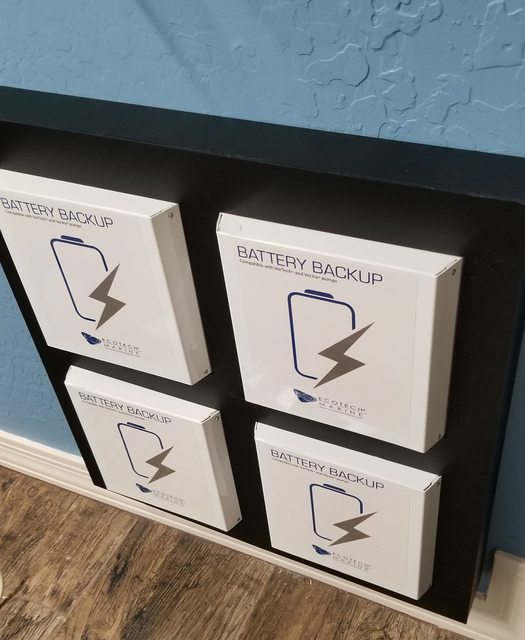

Since yesterday evening this is what my living room looks like:

I had every intention to work on it today but we had a family day, when I got back home this evening, this is what I walked in on, hopefully tomorrow we will make progress on aquascaping.

SawCJack00 was kind enough to give me his extra bucket of E-Marco 400, It's not enough to complete the task but it's a start. Last Thursday, I put in an order for another bucket. In the back of my mind I thought of this as a drug dealer giving me the first one for free!!! Now that I need more.....

As of right now the plan is to make 3 islands in the tank, leaving plenty of open space for fish and coral grow out, but who knows what type of inspiration I will get along the way. Hopefully by days end tomorrow I will make some progress and get at least 1 island in the tank.

And just like that:

1. Build and paint the platform under the tank for the sump DONE

2. Cut out the acrylic for the ghost overflow DONE

3. Glue the overflow DONE

4. Drill holes in the tank for the overflow DONE

5. Drill holes in the tank for the returns DONE

6. Cut and glue all the plumbing for the drain and return DONE

I mapped out the inside of the tank foot print

Since yesterday evening this is what my living room looks like:

I had every intention to work on it today but we had a family day, when I got back home this evening, this is what I walked in on, hopefully tomorrow we will make progress on aquascaping.

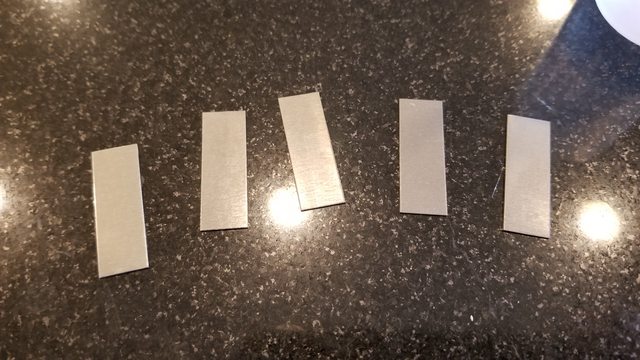

SawCJack00 was kind enough to give me his extra bucket of E-Marco 400, It's not enough to complete the task but it's a start. Last Thursday, I put in an order for another bucket. In the back of my mind I thought of this as a drug dealer giving me the first one for free!!! Now that I need more.....

As of right now the plan is to make 3 islands in the tank, leaving plenty of open space for fish and coral grow out, but who knows what type of inspiration I will get along the way. Hopefully by days end tomorrow I will make some progress and get at least 1 island in the tank.