I have the Syncra SDC pump successfully linked with Apex Fusion, I also have a floor flood sensor, a 4 inch liquid level monitor (In the tank) and a optical sensor (In my PF-800 HOB)

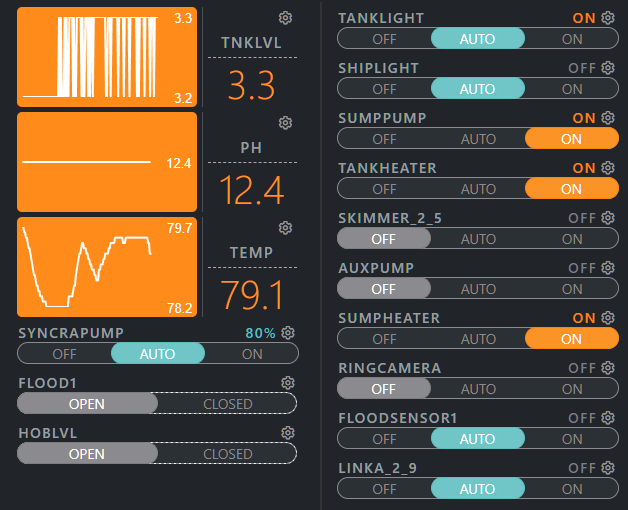

With the Syncra pump I have 2 spots to control things in Fusion, there's the control via the Outlet itself and control via the Syncra pump slider that it adds. I am unsue of where I should be putting my code? At the Outlet level or the Syncra level? I'm including a picture for reference....

SUMPPUMP is the regular outlet control for the Syncra

SYNCRAPUMP is the control that get added when you connect the pump

Currently I have this in the SYNCRAPUMP section and nothing in the SUMPPUMP section

(First 2 lines were default)

Fallback ON

tdata 00:00:00,0,0,80,0,0,0,0,0,0,0,0,0,0

If TNKLVL > 3.4 Then OFF

If HOBLVL CLOSED Then OFF

If Flood1 CLOSED Then OFF

I ran a test by going in and setting the 3.4 in the above to 3.0 and saved it to force test a failure condition.

I assumed that the pump should just shut off as the level is above 3.0, but what happened was the pump shut off and then powered right up again and continued to cycle on and off every 3 seconds or so....

This doesn't seem right so I wonder if I should put the If Then statements in the SUMPPUMP section, but with the Syncra pump it doesnt seem like I can put any programming in the Outlet section....

Side note, while testing the Optical sensor in my PF-800 it reacts so slowly that the HOB would overflow before even triggering, is that normal? (I have it positioned very low down near the water line in the HOB to giver it the most time to react... I assumed this stuff would trigger mostly instantly but maybe that isnt the case?

With the Syncra pump I have 2 spots to control things in Fusion, there's the control via the Outlet itself and control via the Syncra pump slider that it adds. I am unsue of where I should be putting my code? At the Outlet level or the Syncra level? I'm including a picture for reference....

SUMPPUMP is the regular outlet control for the Syncra

SYNCRAPUMP is the control that get added when you connect the pump

Currently I have this in the SYNCRAPUMP section and nothing in the SUMPPUMP section

(First 2 lines were default)

Fallback ON

tdata 00:00:00,0,0,80,0,0,0,0,0,0,0,0,0,0

If TNKLVL > 3.4 Then OFF

If HOBLVL CLOSED Then OFF

If Flood1 CLOSED Then OFF

I ran a test by going in and setting the 3.4 in the above to 3.0 and saved it to force test a failure condition.

I assumed that the pump should just shut off as the level is above 3.0, but what happened was the pump shut off and then powered right up again and continued to cycle on and off every 3 seconds or so....

This doesn't seem right so I wonder if I should put the If Then statements in the SUMPPUMP section, but with the Syncra pump it doesnt seem like I can put any programming in the Outlet section....

Side note, while testing the Optical sensor in my PF-800 it reacts so slowly that the HOB would overflow before even triggering, is that normal? (I have it positioned very low down near the water line in the HOB to giver it the most time to react... I assumed this stuff would trigger mostly instantly but maybe that isnt the case?