So today I started on the NSW mixing tanks at the other end of the house to where the display tank are. These are each 350G, and I go through them reasonably rapidly because I change 20G per day. I used to get (filtered) NSW delivered from Half Moon Bay but that stopped recently, so I wanted to set up an automated-as-possible solution before I run out of my current ~300G-remaining tank....

Here's what they look like:

... they're painted black and also put under black cloth with weighted sandbags to prevent sunlight from powering algae growth. You can see the result of the day's labour, with an Apex set up in a waterproof box and ready to be set up to monitor float switches, and use a solenoid to allow RODI water to come into the tank if we're in "make NSW" mode. The inside of the box looks like:

... so, ready (for two tanks) to have salinity probes, float-switches to determine when the tank is full, control mixing pumps, and have some manual buttons to start sequences of actions going.

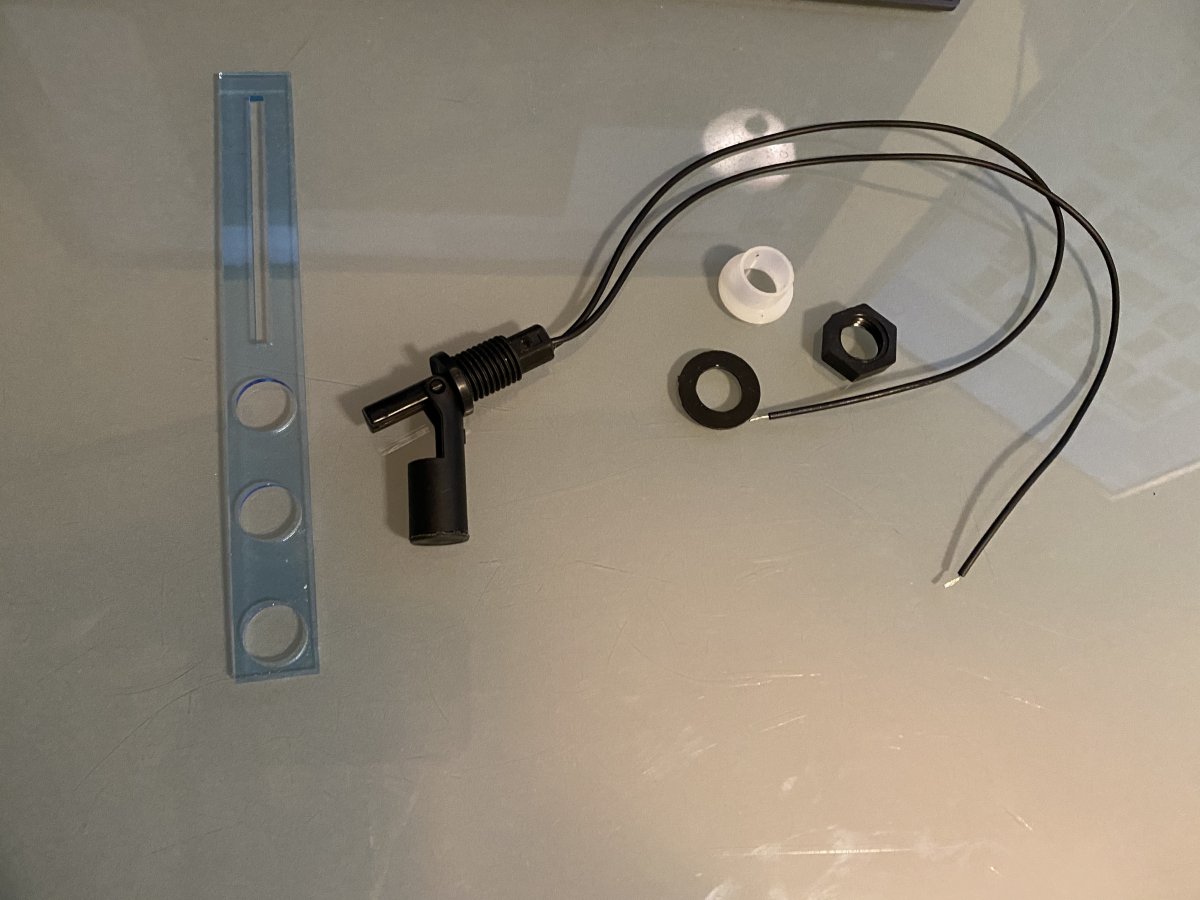

I bought some float switches and needed to mount them, so I fired up the laser cutter and cut out an adjustable bracket to mount at least 2 float switches in (one for level, one set higher for STOP)...

All I need to do to get this to work is put a screw through the vertical part of the top of the tank and adjust it up and down to suit. The float switch then goes on just like:

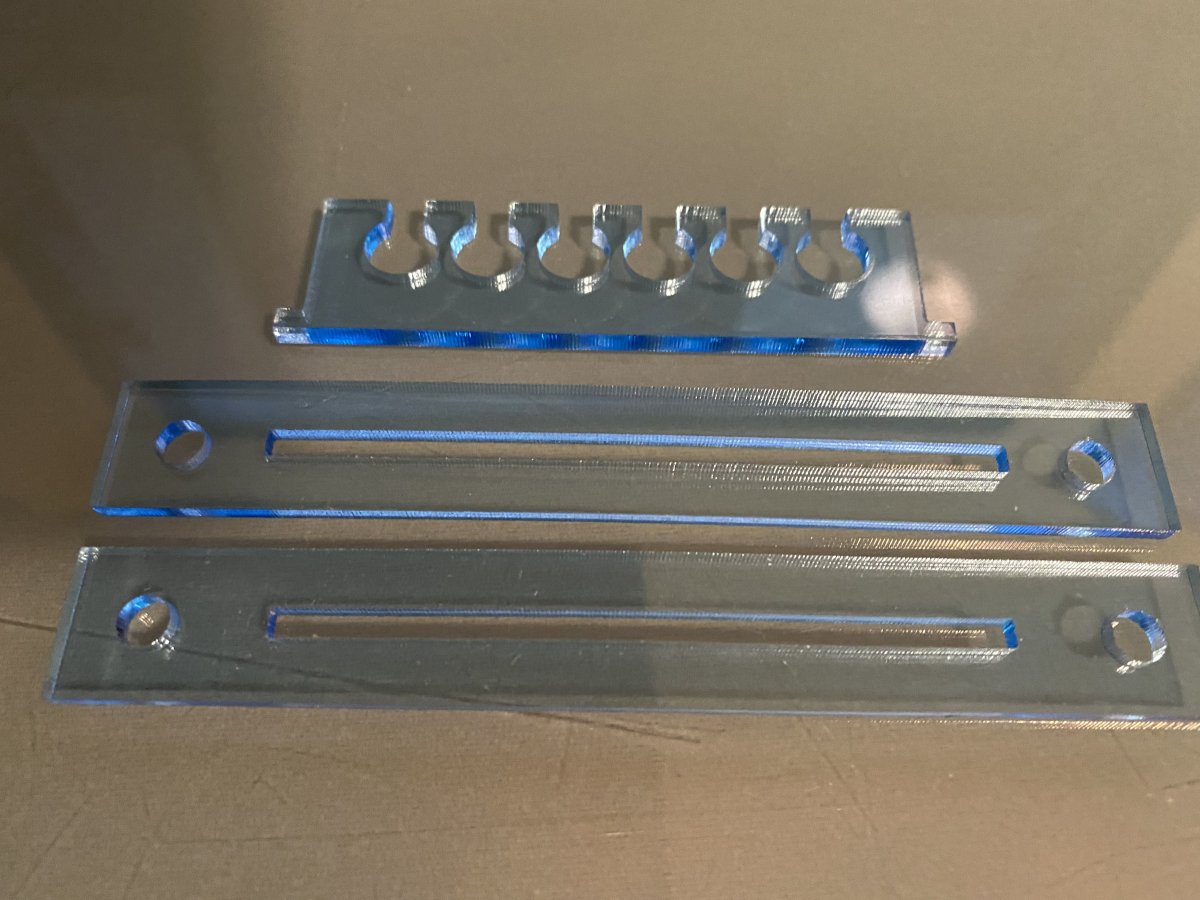

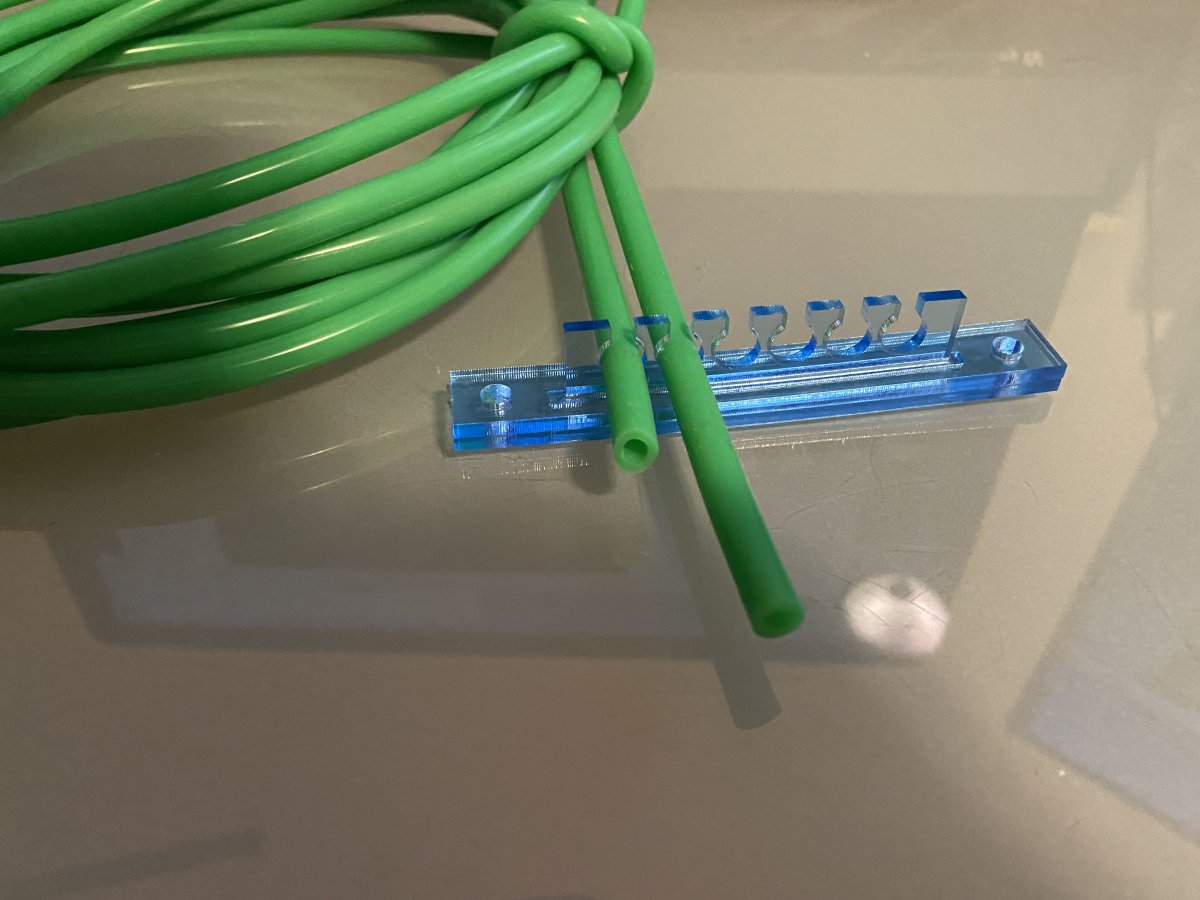

They seem to work well enough in practice. While I had the laser-cutter on, I roughed up an RODI line wall mount for the fish-room. I've got 3 DOS dosers mounted in the fish room, and the lines are untidy. I'd bought several different-coloured 5M lengths of silicone 1/4" tube, so I could easily see what went where, and wanted to mount them on the wall around to the tank and down to the dosing containers. The design looked like:

... which, when assembled, gives me a flush-to-the-wall push-to-fit contraption that looks like (this is the green silicone tubing ...

...

All told, I'm pretty happy with the day's work

Here's what they look like:

... they're painted black and also put under black cloth with weighted sandbags to prevent sunlight from powering algae growth. You can see the result of the day's labour, with an Apex set up in a waterproof box and ready to be set up to monitor float switches, and use a solenoid to allow RODI water to come into the tank if we're in "make NSW" mode. The inside of the box looks like:

... so, ready (for two tanks) to have salinity probes, float-switches to determine when the tank is full, control mixing pumps, and have some manual buttons to start sequences of actions going.

I bought some float switches and needed to mount them, so I fired up the laser cutter and cut out an adjustable bracket to mount at least 2 float switches in (one for level, one set higher for STOP)...

All I need to do to get this to work is put a screw through the vertical part of the top of the tank and adjust it up and down to suit. The float switch then goes on just like:

They seem to work well enough in practice. While I had the laser-cutter on, I roughed up an RODI line wall mount for the fish-room. I've got 3 DOS dosers mounted in the fish room, and the lines are untidy. I'd bought several different-coloured 5M lengths of silicone 1/4" tube, so I could easily see what went where, and wanted to mount them on the wall around to the tank and down to the dosing containers. The design looked like:

... which, when assembled, gives me a flush-to-the-wall push-to-fit contraption that looks like (this is the green silicone tubing

All told, I'm pretty happy with the day's work