- Joined

- Dec 4, 2018

- Messages

- 184

- Reaction score

- 107

Not sure if this project will be successful or not. But I’ve been itching to build something and I have a 180g in the works. I would love a closed loop if I could come up with a random flow generator. Luckily I have a 3d printer. So I don’t have much to loose but a few hours.

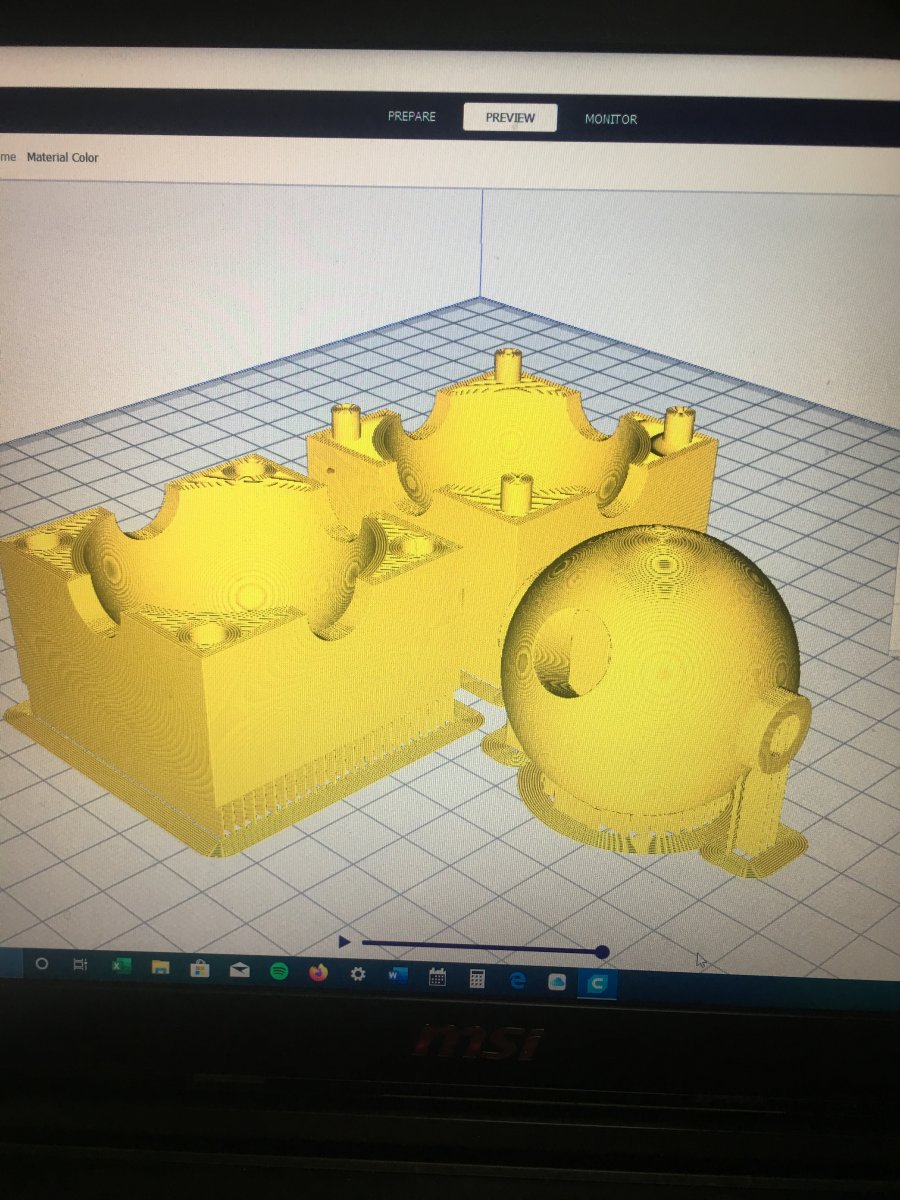

I initially designed a larger 6 port design, but it would have been a large print. So I designed a smaller square version to at least try and see if the design would work. It’s on the printer right now. Should be done in a few hours(14hr print). I’m hoping it’s at least partly successful, so I can hammer out some flaws and maybe make a better design. If you have Any input or ideas to add, I’d love to hear them. The goal is to come up with a random flow generator that won’t break the bank. I’ll post both designs I’ve come up with so far. Both are built with the idea of using a stepper motor to power them.

I initially designed a larger 6 port design, but it would have been a large print. So I designed a smaller square version to at least try and see if the design would work. It’s on the printer right now. Should be done in a few hours(14hr print). I’m hoping it’s at least partly successful, so I can hammer out some flaws and maybe make a better design. If you have Any input or ideas to add, I’d love to hear them. The goal is to come up with a random flow generator that won’t break the bank. I’ll post both designs I’ve come up with so far. Both are built with the idea of using a stepper motor to power them.