Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

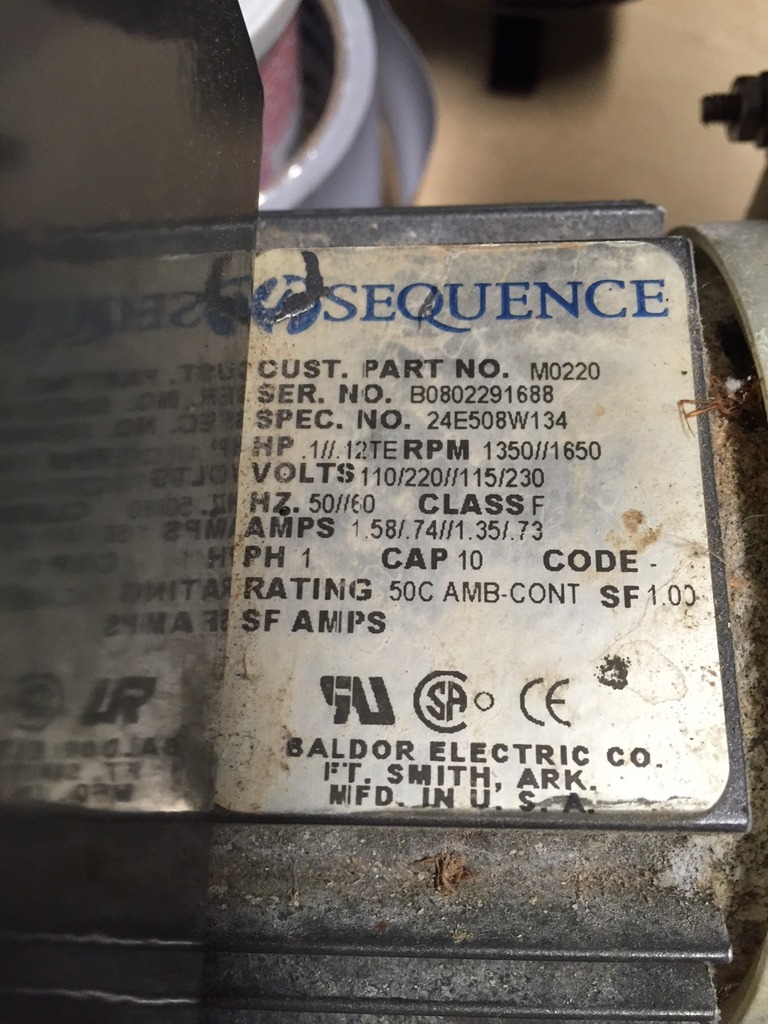

reeflo baldor motor repair

- Thread starter steveb

- Start date

- Tagged users None

- Joined

- Dec 25, 2015

- Messages

- 284

- Reaction score

- 254

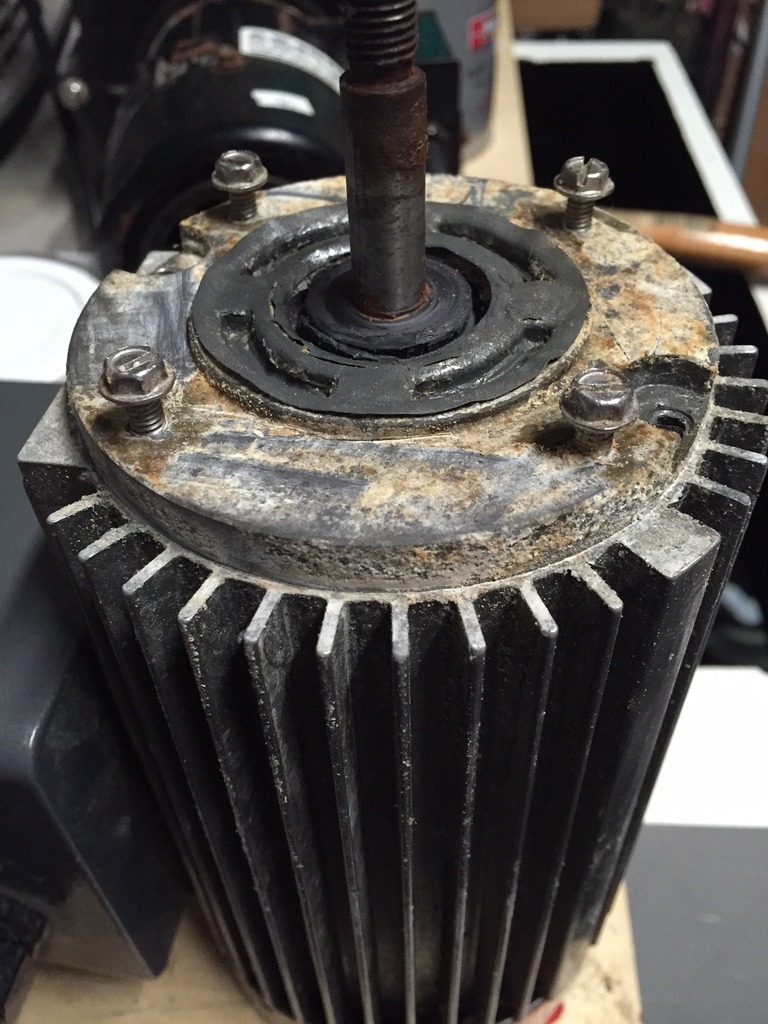

You will defiantly need to remove the fan. The set screw is visible in the last image. The body of the motor should be three parts. The end caps and the heat sink. You should be able to separate the ends from the heat sink. Force may be necessary. Then the shaft with the bearings should just slide out.

I haven't worked on this exact motor but it is very similar in appearance to one I have worked on so I may not be correct but that is where I would start.

I haven't worked on this exact motor but it is very similar in appearance to one I have worked on so I may not be correct but that is where I would start.

yeah its actually removed (or at least the set screw is), still need to pull the fan. I just wanted to make sure I was going down the right path. More than likely the motor is toast as it does not spin. I'm mostly wanting to see if it is just bearings or more. Also depending on what I see I might take to a electric motor shop for repair or end up tossing it in the trash.

- Joined

- Dec 25, 2015

- Messages

- 284

- Reaction score

- 254

If you decide to toss it, take it to a recycle place and get the cash. It is probably worth about $5.00. There is one on Aldine-Westfield near my house. Otherwise, I am interested in it. I like tinkering with things!

I was able to tap the rotor shaft to get it to come apart. I then pulled the shaft from the top housing piece which contains one of the two bearings. The top bearing is definitely frozen, but the bottom one is fine..

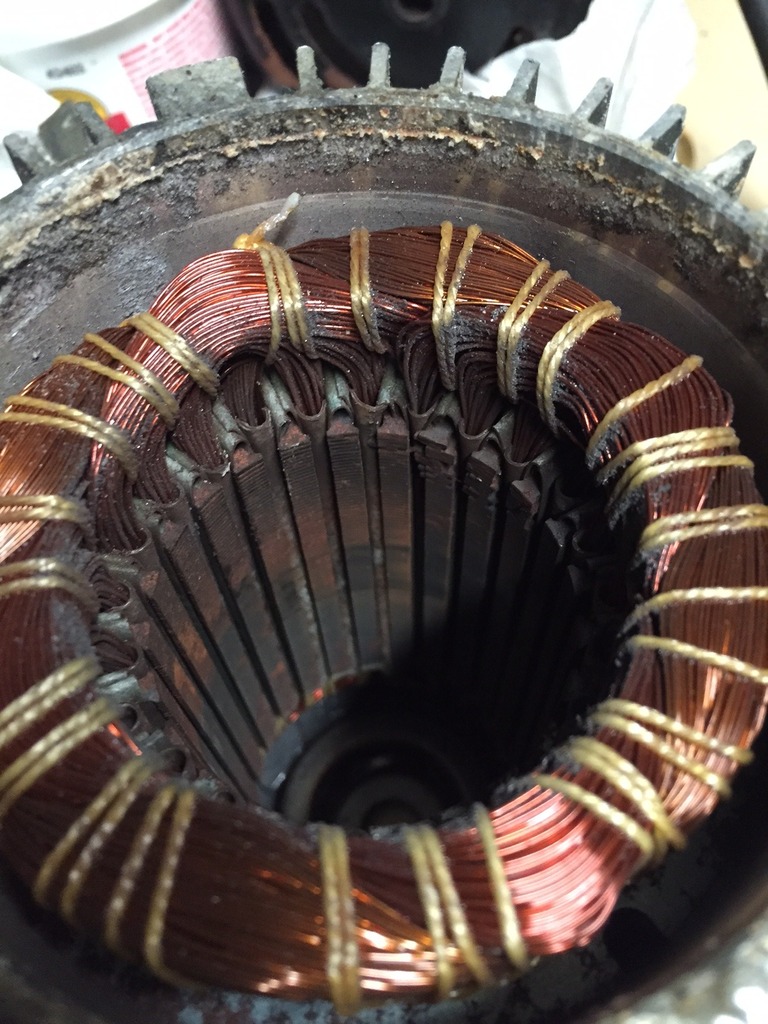

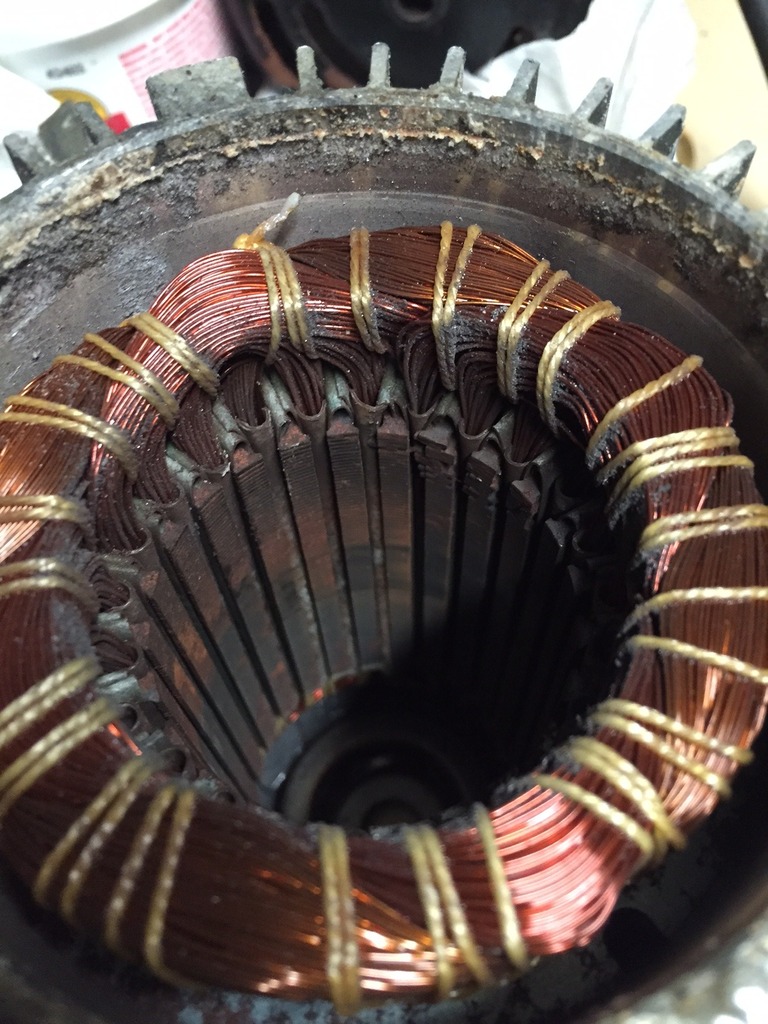

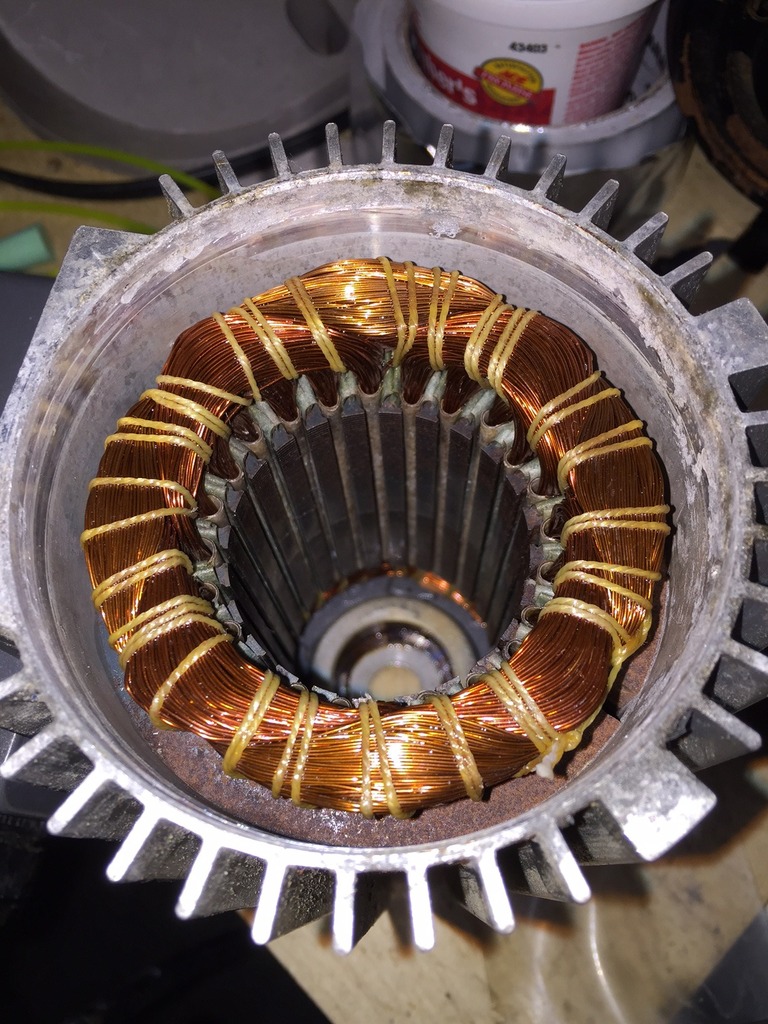

more concerned about the rotor and stator showing some rust. Is this repairable by either me or a electric motor shop?

more concerned about the rotor and stator showing some rust. Is this repairable by either me or a electric motor shop?

For grins and giggles I tapped around on the front bearing and put some oil in it and low and behold it freed up. So I put the motor back together loosely and wow it runs.. noisy as all get out..

Still looking for opinions on the rotor/stator. What needs to be done?

I know some of you are thinking why is he doing this? Mostly bored but I need a stronger mixing pump. I have a spare reeflo seal kit so...

Still looking for opinions on the rotor/stator. What needs to be done?

I know some of you are thinking why is he doing this? Mostly bored but I need a stronger mixing pump. I have a spare reeflo seal kit so...

- Joined

- Dec 25, 2015

- Messages

- 284

- Reaction score

- 254

Im the same way. I like to mess with things to see if I can get them working. I would think that with everything greased up you should be fine. Replace the bearings and as you probably know, It will be much quieter. I can usually find any bearings I need at Granger on the North Freeway.

As long as the windings (copper wires) in the stator are in good shape, I would not worry about rust on the rotor or stator laminations. They are made of low grade carbon steel for good electo-magnetic properties. Take a little emory cloth or scotch brite and clean them up unit smooth. You should definitely replace the bearings. You might need to contact a motor shop to get the proper size unless you can read the bearing size on the bearings themselves (you should always replace both), To put the new bearings on, use gloves as the oil on your hands can cause the bearings to rust where you touch them. I have pulled bearings off of larger motors and seen perfect rust finger prints. Wipe the new bearings with a paper towel to clean off the packing grease and wrap them in aluminum foil. Put the bearings in the oven at 225 degrees F for about 45 minutes (you should warm up the oven with the bearings in it). Make sure the shafts are clean then quickly remove one bearing at a time and slide it onto the shaft making sure the inner race of the bearing slides up against the collar on the shaft.

the bearings I took off had 6200zc3 stamped on them. I ordered 6200zzc3 replacements from zoro tools.

I like your directions on the bearings - heating them to avoid having to use a press to get them on and not touching them with bare skin. I probably would have done that at some point. Thank you.

I have cleaned up the stator (used emory cloth and scotchbrite pad), once done I hosed it down with electrical contact cleaner and then put a light oil on the lamination's.

I also took a piece of cloth and put the rotor in my drill, ran it high speed and took the scrotchbrite (00 steel wool equivalent) pad and removed most of the rust from the lamination's.. I need to get a picture.

I like your directions on the bearings - heating them to avoid having to use a press to get them on and not touching them with bare skin. I probably would have done that at some point. Thank you.

I have cleaned up the stator (used emory cloth and scotchbrite pad), once done I hosed it down with electrical contact cleaner and then put a light oil on the lamination's.

I also took a piece of cloth and put the rotor in my drill, ran it high speed and took the scrotchbrite (00 steel wool equivalent) pad and removed most of the rust from the lamination's.. I need to get a picture.

Last edited:

seal kit PS 163 - STANDARD SEAL - LIBERTY POOL PRODUCTS - not 100% sure its reef safe but looks identical to the reeflo kit.. others have indicated that they have been using for 2+ years with no ill effects..

viton seal kit PS 163V - OZONE SALT SEAL - LIBERTY POOL PRODUCTS

or go with the reeflo kit PARTS

bearing 6200zzc3 (for ReeFlo pumps with Sequence/Baldor motors M-0220)

bearing r6zz (for ReeFlo AO Smith motor JF2K024N)

I also purchased a "Shaft Oil Seal TC10x22x7 Rubber Covered Double Lip w/Garter Spring ID 10mm OD 22mm 10x22x7" from avxseals.com to replace the busted rubber seal and busted fiber seal on the baldor motor and ao smit respectively. Will update if this works out. Its just a better seal to keep crap out of the front bearing should the volute shaft seal fail again.

viton seal kit PS 163V - OZONE SALT SEAL - LIBERTY POOL PRODUCTS

or go with the reeflo kit PARTS

bearing 6200zzc3 (for ReeFlo pumps with Sequence/Baldor motors M-0220)

bearing r6zz (for ReeFlo AO Smith motor JF2K024N)

I also purchased a "Shaft Oil Seal TC10x22x7 Rubber Covered Double Lip w/Garter Spring ID 10mm OD 22mm 10x22x7" from avxseals.com to replace the busted rubber seal and busted fiber seal on the baldor motor and ao smit respectively. Will update if this works out. Its just a better seal to keep crap out of the front bearing should the volute shaft seal fail again.

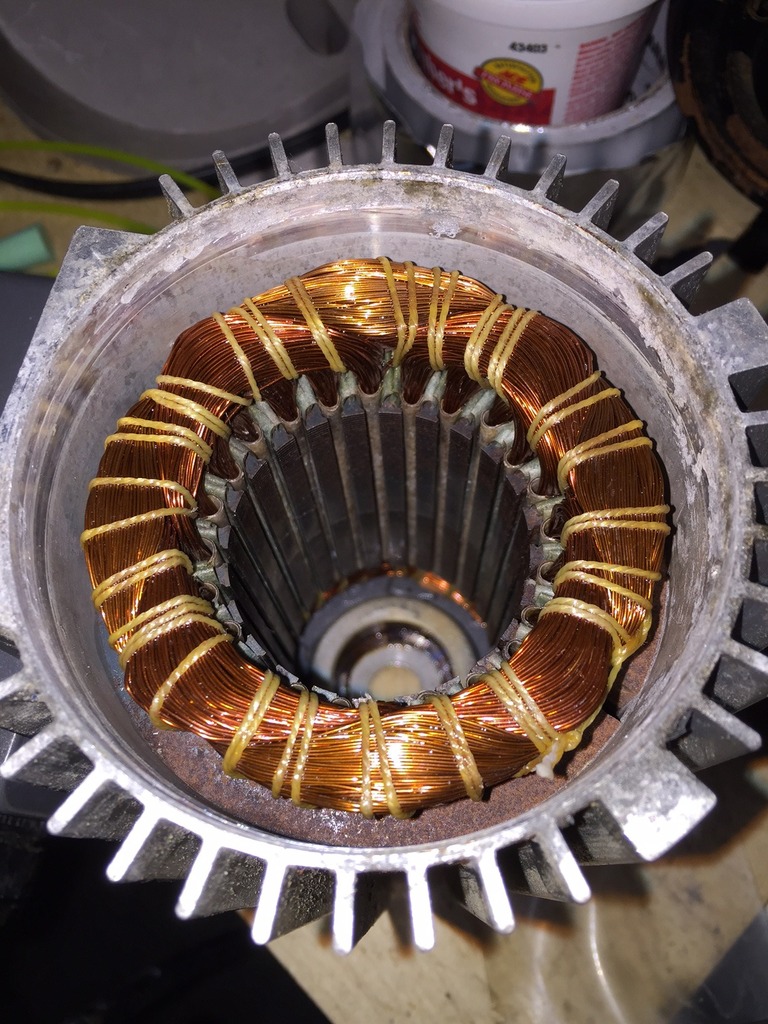

replaced the bearings, cleaned up the rust. Not sure I'm totally happy with it (sound) at the moment but considering it was frozen up maybe ok. Wondering if a motor shop could do a better job of balancing the shaft...

All three pumps are finito!

All have new bearings (zz), new seals, new O-rings, new dart impellers, motor metal was wire brushed/sanded and painted (were applicable), new volute bolts and nuts, and a lot of the machine screws were replaced due to rust.

I will try to get some closeups here shortly. Now I need to build a test rig to hook these up to...

All have new bearings (zz), new seals, new O-rings, new dart impellers, motor metal was wire brushed/sanded and painted (were applicable), new volute bolts and nuts, and a lot of the machine screws were replaced due to rust.

I will try to get some closeups here shortly. Now I need to build a test rig to hook these up to...

I'm so glad I found this thread. I have a very old Baldor that has started screeching and my Sequence sticker looks identical to yours. I assume it's the bearings and have been looking for a while to determine which ones to get. Did you replace the drive shaft? Mine has a lot of rust where the impeller attaches and I'd like to change it while I have everything apart.

No I didn't change out the drive shaft. Mine had some light rusting but I removed it when I had the shaft out to replace the bearings. I removed the rust from the shaft by using emery cloth on it while the motor was running (trying to keep it balanced..).

Well that was a well put together thought and sentence..

When I had the shaft out I removed the rust from rotor and stator,

I then replaced the bearings, then when I re-assembled the motor, before the pump housing was re-attached, I ran the motor on the bench and used emery paper to clean the shaft.

When I had the shaft out I removed the rust from rotor and stator,

I then replaced the bearings, then when I re-assembled the motor, before the pump housing was re-attached, I ran the motor on the bench and used emery paper to clean the shaft.

Similar threads

- Replies

- 5

- Views

- 132

- Replies

- 5

- Views

- 186

- Replies

- 2

- Views

- 170

- Price: 250

- Shipping Available

- Replies

- 4

- Views

- 349

- Replies

- 2

- Views

- 72

New Posts

-

-

Nebraska Live Goods SPONSOR Fresh Live 10 Species Phytoplankton Blend

- Latest: Reef By Steele

-