- Joined

- Nov 21, 2016

- Messages

- 646

- Reaction score

- 362

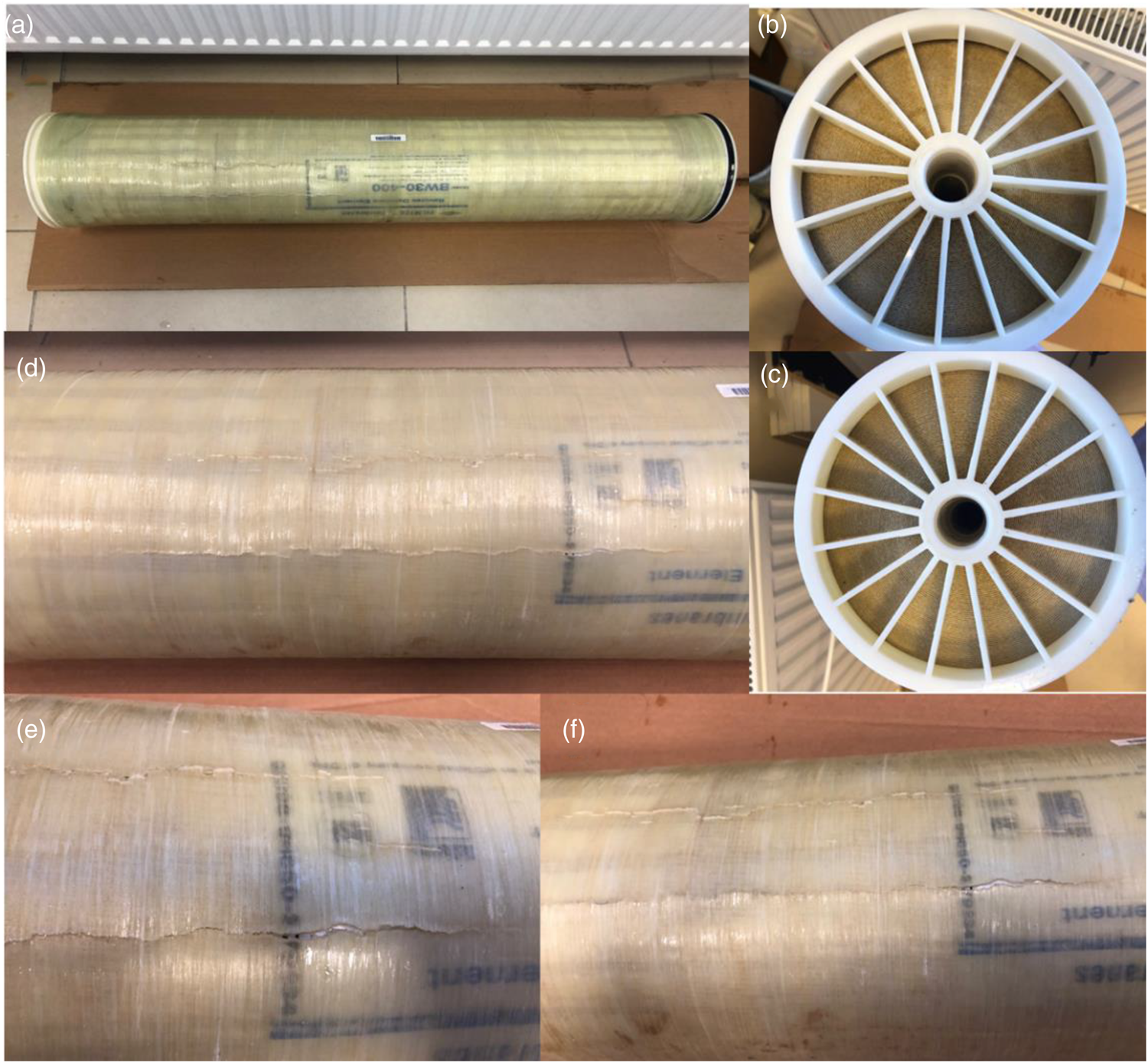

I’m having terrible problems with the filmtec ro membranes that BRS sells. The membrane fails in 5-6 months like clock work. When I unroll the membrane there is cracks in the film. I’ve tried everything I could think of and BRS has been very helpful in trouble shooting the problem. I’ve tried changing the carbon block every few months, I’ve contacted my water management office and they tell me only a small amount of chlorine is used, no chloramines are used, even when the membrane has failed the is no trace of chlorine in the product water. The membrane is not drying out between use and the supply water has been tried @50 to 60 psi and cool water not warm or hot. Keep in mind in this 5-6 month time I’m only making about 150-200 gallons of water.

my tds runs 350-450

With all new filters and membrane the tds will be as low as 8-15 going into my DI.

as the membrane fails the tds going into the DI increases rapidly

my question is, is anyone else having this problem with these membranes? And is there any other suggestions you might have to correct the problem?

my tds runs 350-450

With all new filters and membrane the tds will be as low as 8-15 going into my DI.

as the membrane fails the tds going into the DI increases rapidly

my question is, is anyone else having this problem with these membranes? And is there any other suggestions you might have to correct the problem?