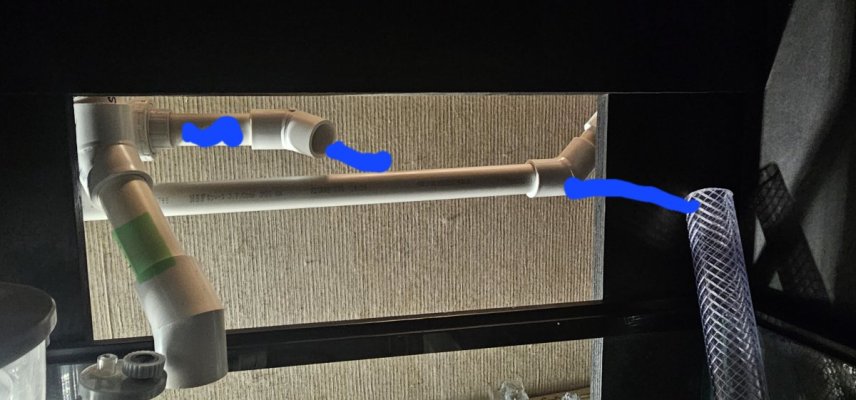

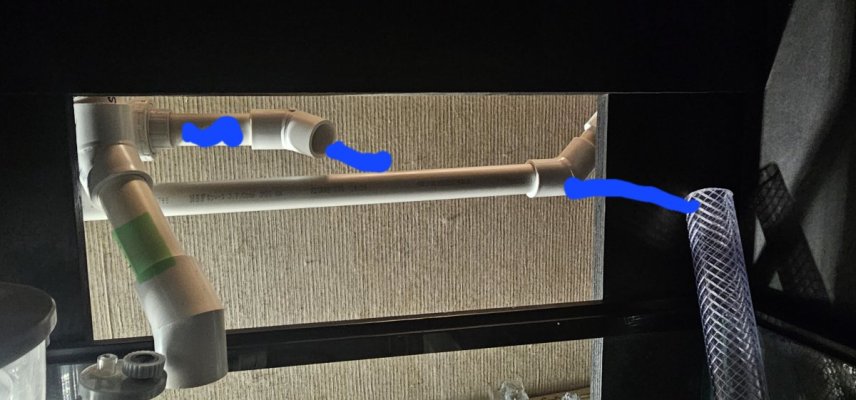

First time plumbing a tank, it's all dry fitted finally. I ran out of 3/4 pvc so going to finish tomorrow, just the pipe to the pump. But overflow/ emergency drain and return is done. I placed unions where I thought was needed, are they in the right spots?

I'm connecting vinyl hose from the pump to the pvc with that fitting its threaded , is it the right fitting I need? Couldn't find plastic hose clamps locally cant I just use zip ties ? Thanks for the help, p,s blue is return to pump in pics, do I add union after pump hose to pvc connection?

I'm connecting vinyl hose from the pump to the pvc with that fitting its threaded , is it the right fitting I need? Couldn't find plastic hose clamps locally cant I just use zip ties ? Thanks for the help, p,s blue is return to pump in pics, do I add union after pump hose to pvc connection?