- Joined

- Feb 3, 2018

- Messages

- 525

- Reaction score

- 567

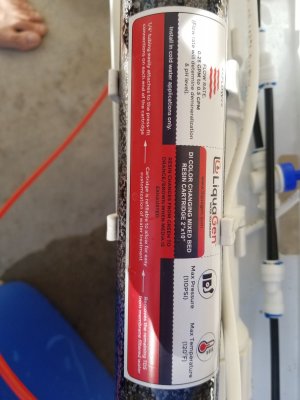

So I have a 5 stage RODI. This morning, I changed all my filters cause my tds was 0.01 and my resin looked like it was exhausted (all orange). I started making new water and my first 5 gallon batch came as a tds of 0.03. I figured maybe since it was the first batch, it wasnt completely clean so i tossed it and made a new 5 gallon batch with a different container and it still came out 0.03 tds. I checked my tds meter with my older rodi water and it read 0.01. The new filters have been laying around for a few months. Ive changed filters 3-4 times already and never had this problem. Any thoughts?