Well I was able to get some more done on the stand over the past few days and it has turned out pretty well. When I was putting the siding on the stand I noticed that the bottom piece of wood that the doors would rest on would not be wide enough for them seems like I missed a calculation somewhere. So Since I still needed to come up with an idea on how to cover up the bottom to make it look good I brought the kerfing technique back into the picture to get the job done. This way I am able to extended the bottom piece of wood far enough out for the doors and make it look good all at the same time.

So I went out and got a piece of poplar wood to get started I got a 1x4 from ace hardware.

The panel up front for the wood to be added too.

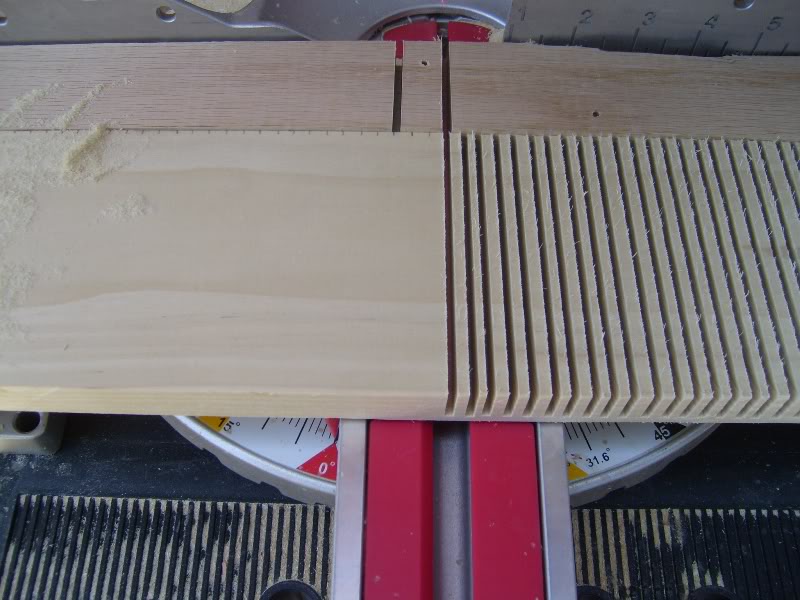

This is what it looked like before the cutting began.

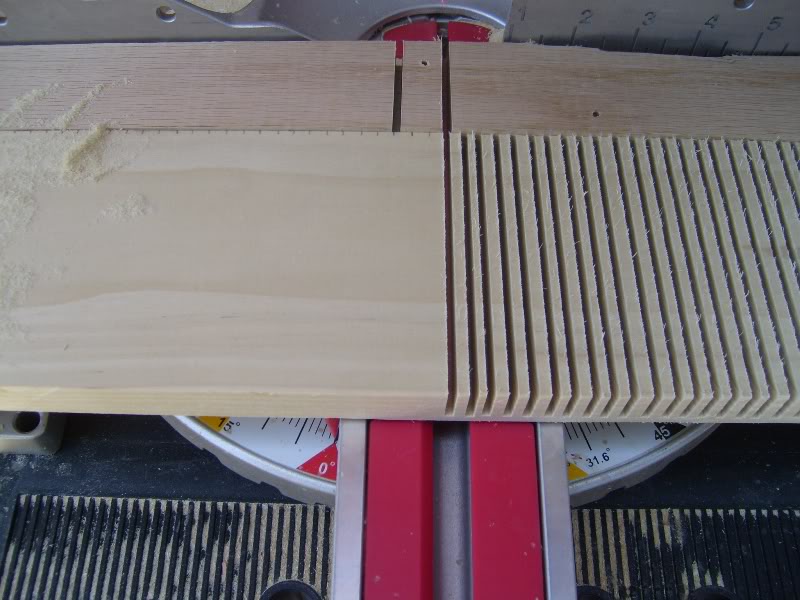

And this is what it looked like after the kerfing technique.

I have gotten pretty good at this technique and can now say I am a kerfing expert!

So after that I got the piece set up to be glued to the bottom panel. Supplies were needed I need lots of glue and lots of wood clamps ranging in size, as you can see it set up.

Poplar set up and ready to go.

Glue added and clamps on!

Looks good doesn’t it well here is some bad new remember how I said that I had gotten 1x4 wood well my thinking was that I need to get a piece that was 4 1/4†in order to make it fit perfect but I thought that a 4†would be enough and we wouldn’t be able to tell the difference. Well since I didn’t measure the piece of wood I later found out that at ace they go by another method of measuring wood so it is only a 3 1/2†piece of wood. Since it is that small it won’t work so after I realized this I took all the clamps off and got the wood off before the glue dried. So I went back out to Home Depot this time with a measuring tape to be sure to get the right piece of wood. When I got there I look at their way of measuring and it is accurate (why can’t they all be on the same page) well I got a 5 1/2†piece and I will trim it the size on a table saw.

All trimmed the process begins again.

Half way done.

Close up shot every 1/4â€

Clamped on!

So I went out and got a piece of poplar wood to get started I got a 1x4 from ace hardware.

The panel up front for the wood to be added too.

This is what it looked like before the cutting began.

And this is what it looked like after the kerfing technique.

I have gotten pretty good at this technique and can now say I am a kerfing expert!

So after that I got the piece set up to be glued to the bottom panel. Supplies were needed I need lots of glue and lots of wood clamps ranging in size, as you can see it set up.

Poplar set up and ready to go.

Glue added and clamps on!

Looks good doesn’t it well here is some bad new remember how I said that I had gotten 1x4 wood well my thinking was that I need to get a piece that was 4 1/4†in order to make it fit perfect but I thought that a 4†would be enough and we wouldn’t be able to tell the difference. Well since I didn’t measure the piece of wood I later found out that at ace they go by another method of measuring wood so it is only a 3 1/2†piece of wood. Since it is that small it won’t work so after I realized this I took all the clamps off and got the wood off before the glue dried. So I went back out to Home Depot this time with a measuring tape to be sure to get the right piece of wood. When I got there I look at their way of measuring and it is accurate (why can’t they all be on the same page) well I got a 5 1/2†piece and I will trim it the size on a table saw.

All trimmed the process begins again.

Half way done.

Close up shot every 1/4â€

Clamped on!