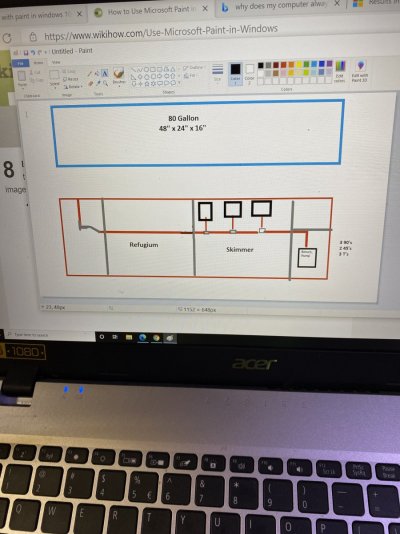

I am restarting my reef new after Sterilizing everything due not quarantining. I am making some changes in my plumbing and I am looking for any comments and or suggestions on the best way to go.

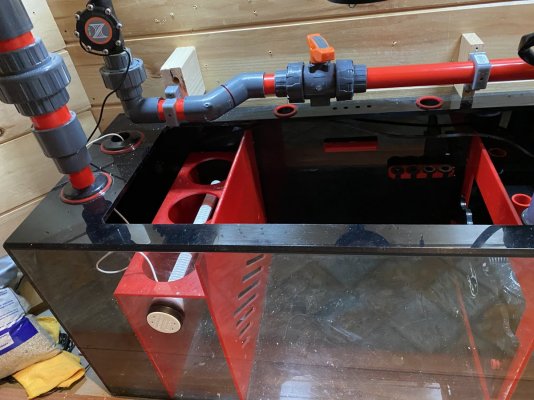

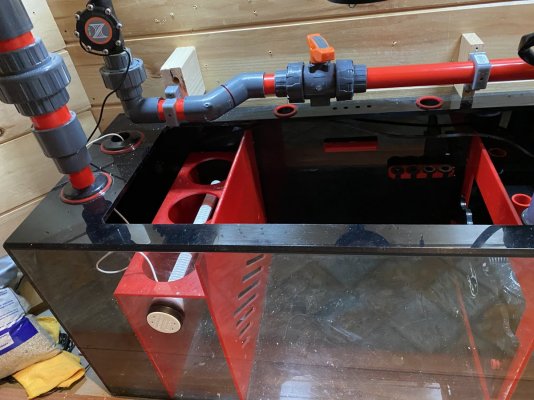

I am running the Triton Method and I have modified my sump. At first I had allot of problems with algae getting to the return pump came to find that the biggest problem was the Sea Lettuce once I took that out didn't have to many problems once I put the plate in you can see before the Skimmer Section.

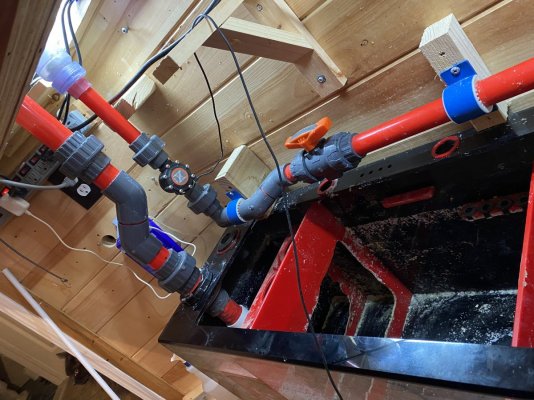

I am using a Syncra Silent Sicce 5.0 pump (1321GPH) That gives me 550 GPH at the flow sensor located where the return line goes to the Tank.

I will be using a Red Sea Reef Wave 25 on the far end of my Peninsula style tank.

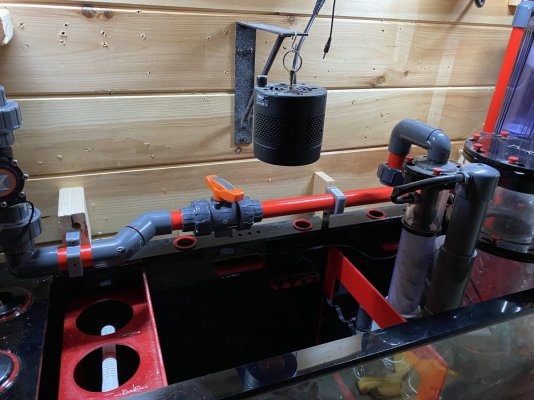

I was using a small pump that I could just fit next to my Skimmer pump. I am looking to go to a manifold to run my Carbon and GFO reactors and I would like to plumb in another Reactor that I could use when I wanted to run a sediment filter when I want to. Right now I just hang one with a small pump if I want to polish water.

That being said if you can understand me what would be the right size return pump if I go that way and can I get enough Flow from my 2 return nozzles on the overflow side of the tank for a Mixed Reef.

I am running the Triton Method and I have modified my sump. At first I had allot of problems with algae getting to the return pump came to find that the biggest problem was the Sea Lettuce once I took that out didn't have to many problems once I put the plate in you can see before the Skimmer Section.

I am using a Syncra Silent Sicce 5.0 pump (1321GPH) That gives me 550 GPH at the flow sensor located where the return line goes to the Tank.

I will be using a Red Sea Reef Wave 25 on the far end of my Peninsula style tank.

I was using a small pump that I could just fit next to my Skimmer pump. I am looking to go to a manifold to run my Carbon and GFO reactors and I would like to plumb in another Reactor that I could use when I wanted to run a sediment filter when I want to. Right now I just hang one with a small pump if I want to polish water.

That being said if you can understand me what would be the right size return pump if I go that way and can I get enough Flow from my 2 return nozzles on the overflow side of the tank for a Mixed Reef.