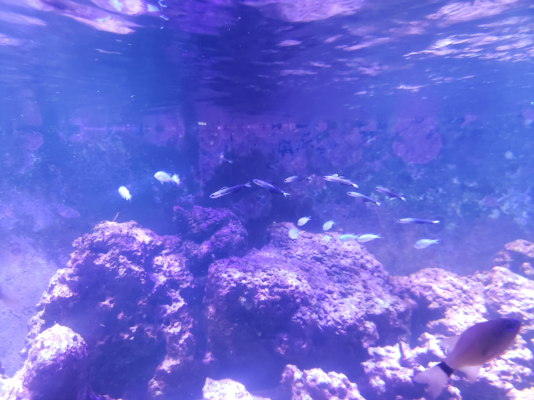

The moon light you have created is amazing! It's definitely on my reef bucket list.

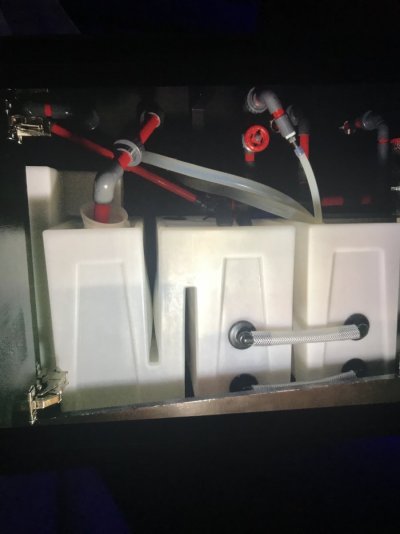

Bummer, all the anthias passed? You will probably hate starting it but once you simply the return plumbing you can sleep easier.

What do you mean by a modified bean animal?

Bummer, all the anthias passed? You will probably hate starting it but once you simply the return plumbing you can sleep easier.

What do you mean by a modified bean animal?