- Joined

- Oct 1, 2017

- Messages

- 3,060

- Reaction score

- 2,523

1- Let’s start with needle valve off or all the way open

2- not sure why you need the needle valve if flow restrictor is working and sized right. The capillary , when used with flush kit, should be placed in small piece of tube in between two y connections, parallel to flush valve. And tail end of capillary pointing in direction with flow of water

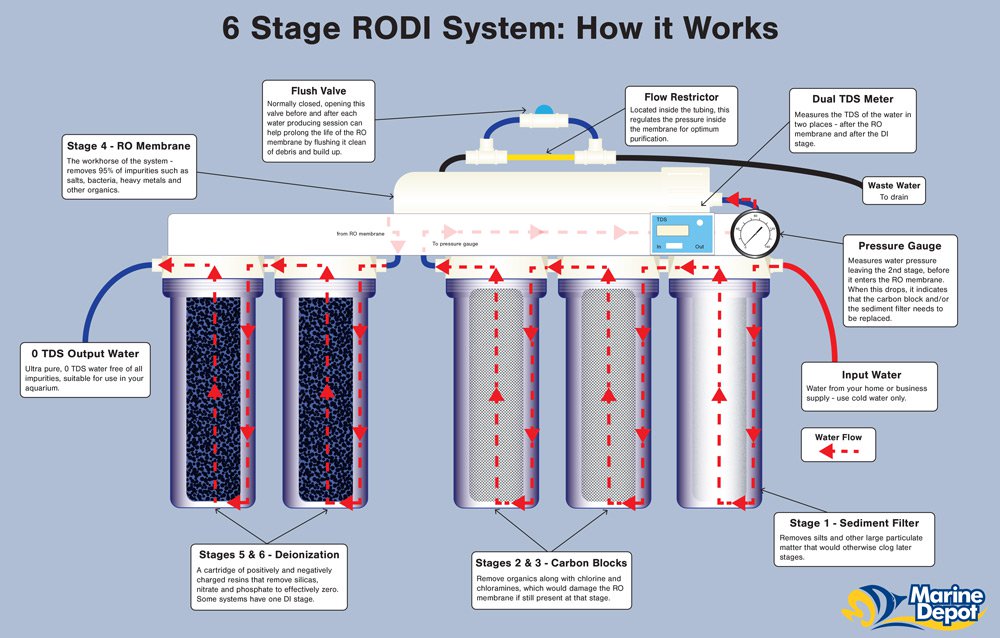

3-should be booster pump, then whatever particle filters, then carbon block which you don’t need because you’re on well, then membrane, then silica buster , maxcap whatever, then di resin

Also will note that on membrane you have on one side a single fitting that goes in to membrane from cartridges.

On the other side there are 2. The one in center continues out to eventually become product. The other one is off center and goes to waste

2- not sure why you need the needle valve if flow restrictor is working and sized right. The capillary , when used with flush kit, should be placed in small piece of tube in between two y connections, parallel to flush valve. And tail end of capillary pointing in direction with flow of water

3-should be booster pump, then whatever particle filters, then carbon block which you don’t need because you’re on well, then membrane, then silica buster , maxcap whatever, then di resin

Also will note that on membrane you have on one side a single fitting that goes in to membrane from cartridges.

On the other side there are 2. The one in center continues out to eventually become product. The other one is off center and goes to waste

Last edited: